Editor's Note: Take a look at our featured best practice, End-to-end (E2E) Operating Model Transformation (30-slide PowerPoint presentation). In many industries, executives have had their hands full staying competitive and surviving market downturns. This is done by making cuts, often silo by silo, and occasionally in ways that negatively affected customers.

It is time for organizations to rework their Operating Models in a new way, [read more]

Also, if you are interested in becoming an expert on Process Improvement, take a look at Flevy's Process Improvement Frameworks offering here. This is a curated collection of best practice frameworks based on the thought leadership of leading consulting firms, academics, and recognized subject matter experts. By learning and applying these concepts, you can you stay ahead of the curve. Full details here.

* * * *

A recent report from AlixPartners posited a surprising finding in the field of Process Improvement Programs for manufacturers: Most companies engaged in Lean Management, Sigma Six, or another management philosophy are achieving a poor return on their investment, and appear to be only partially engaged in the process itself. Considering that the entire purpose of a CI program is to reduce costs, a lax ROI is one of the last results one might expect to find, but going by the observations of Steve Maurer, Head of the Manufacturing Practice at AlixPartners, it’s clear that these disappointing numbers are not a failure of Continuous Improvement, but rather skewed perceptions and flawed applications

A recent report from AlixPartners posited a surprising finding in the field of Process Improvement Programs for manufacturers: Most companies engaged in Lean Management, Sigma Six, or another management philosophy are achieving a poor return on their investment, and appear to be only partially engaged in the process itself. Considering that the entire purpose of a CI program is to reduce costs, a lax ROI is one of the last results one might expect to find, but going by the observations of Steve Maurer, Head of the Manufacturing Practice at AlixPartners, it’s clear that these disappointing numbers are not a failure of Continuous Improvement, but rather skewed perceptions and flawed applications

Many manufacturers, particularly those who are achieving sub-par returns, have an idea that CI is simply a philosophy change, and not a capital investment.

Continuous Improvement (CI), sometimes called Continual Improvement, is the ongoing improvement of products, services or processes through incremental and breakthrough improvements. These efforts can seek “incremental” improvement over time or “breakthrough” improvement all at once.

Very often Organizational Leadership is disappointed with the results of their business improvement activities. This is usually because they do not make the changes needed to fully integrate improvement skills and behaviors into the daily work of their entire team, including the Leadership.

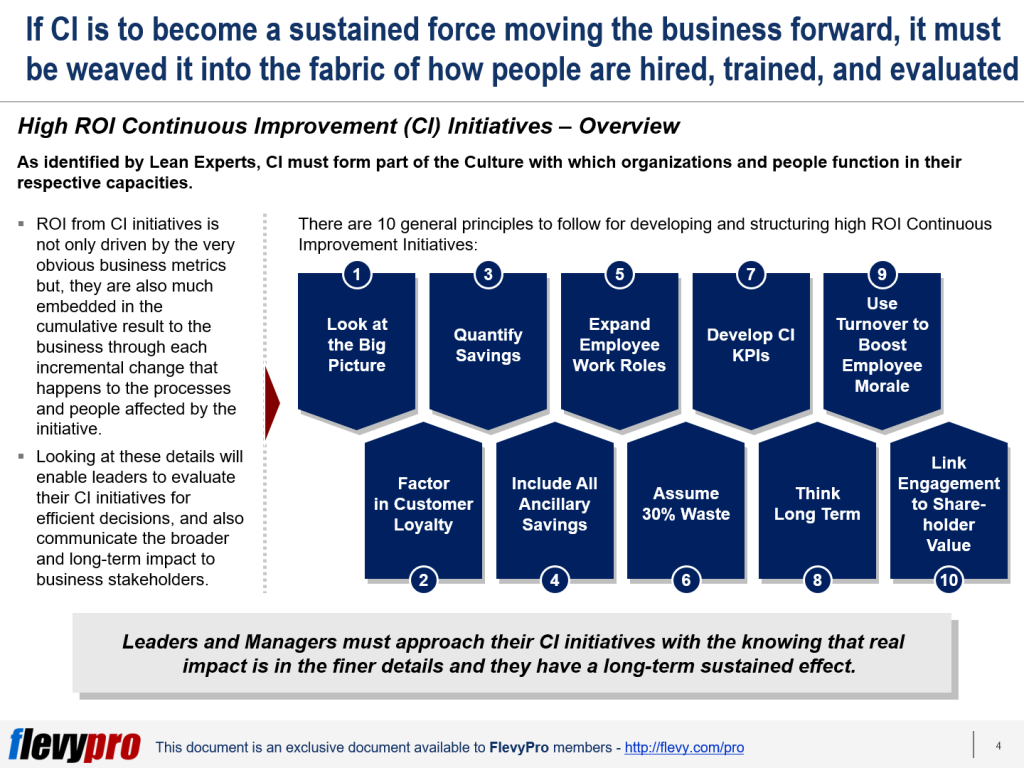

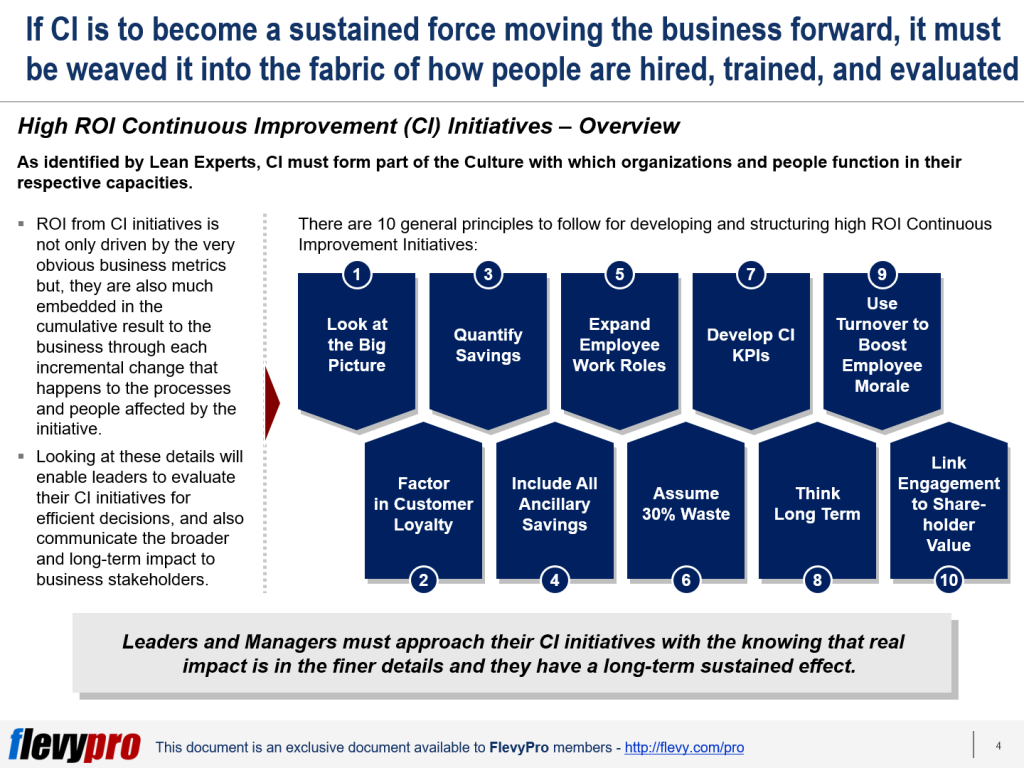

If Continuous Improvement is to become a sustained force moving the business forward, it must be weaved it into the fabric of how people are hired, trained, and evaluated.

As identified by Lean Experts, CI must form part of the Culture with which organizations and people function in their respective capacities.

- ROI from CI initiatives is not only driven by the very obvious business metrics but, they are also much embedded in the cumulative result to the business through each incremental change that happens to the processes and people affected by the initiative

- Looking at these details will enable leaders to evaluate their CI initiatives for efficient decisions, and also communicate the broader and long-term impact to business stakeholders

Lean experts point out 10 general guidelines for developing and structuring high ROI Continuous Improvement Initiatives:

Brief Outline

- Look at the Big Picture – Leaders and managers working on Continuous Improvement projects are typically focused on optimization, waste elimination, capacity utilization, process redesign, and other operational challenges. This focus can lead to a lack of big picture perspective. When calculating ROI, it is important to adopt a higher-level, big picture perspective, so that our ROI calculation is complete and not missing important components that could add up.

- Factor in Customer Loyalty – Continuous Improvement activities are seen to generate Customer Loyalty, an outcome which is often overlooked. Customer Loyalty increases sales and profitability, so it is a factor that should be included in ROI calculations.

- Quantify Savings – Savings estimation of Continuous Improvement initiative builds stakeholder confidence and generates the necessary excitement to foster collaboration from internal teams.

- Include All Ancillary Savings – Ancillary Savings estimation of Continuous Improvement initiative builds stakeholder confidence and generates the necessary excitement to draw participation from internal teams

- Expand Employee Work Roles – Work role expansion of employees have a direct influence on bottom line of the business .When employees who execute, are given more empowerment and expanded roles, they are seen to connect deeper with the business and deliver more value to customers

- Assume 30% Waste – The extent of waste in processes can be considered at 30% at the beginning of an improvement project to set a hypothetical baseline for estimating the potential

- Develop CI KPIs – Improvement initiatives must set the right KPIs and then estimate how those KPI achievement would translate into dollar value immediately and over the years.

- Think Long term – While short-term impact measurements are needed, long-term benefits must also be measured and quantified to understand the ROI impact of the CI initiative over a longer time horizon.

- Use Turnover to Boost Employee Morale – Positive turnover through waste reduction provide opportunities to improve ROI while parallelly boosting employee morale and also defer OPEX category investments. Use the KPIs of waste reduction, and improved performance to boost the morale of employees and ensure to communicate how these business improvements will benefit them

- Link Engagement to Stakeholder Value – Profitability is directly linked to efficient functioning of a business and this in turn is closely connected to the efficiency of the workforce. An engaged employee base increases profitability and thereby Shareholder Value.

Interested in gaining more understanding of these 5 steps to successful High ROI Continuous Improvement Initiatives? You can learn more and download an editable PowerPoint about Continuous Improvement: High ROI Initiatives here on the Flevy documents marketplace.

Are you a Management Consultant?

You can download this and hundreds of other consulting frameworks and consulting training guides from the FlevyPro library.

254-slide PowerPoint presentation

[

NOTE: Our Kaizen presentation has been trusted by an array of prestigious organizations, including industry leaders such as

Apple,

Bayer,

University of Michigan,

General Motors,

Cummins,

Johnson Controls,

Ulta,

Daimler Truck,

Aramark,

Parsons [read more]

Want to Achieve Excellence in Process Improvement?

Gain the knowledge and develop the expertise to become an expert in Process Improvement. Our frameworks are based on the thought leadership of leading consulting firms, academics, and recognized subject matter experts. Click here for full details.

Process Improvement involves analyzing and improving existing business processes in the pursuit of optimized performance. The goals are typically to continuously reduce costs, minimize errors, eliminate waste, improve productivity, and streamline activities.

As we continue to deal with COVID-19 and its economic aftermath, most organizations will prioritize Business Process Improvement initiatives. This is true for a few reasons. First, Process Improvement is one of the most common and effective ways of reducing costs. As the global economy slows down, Cost Management will jump to the forefront of most corporate agendas.

Secondly, a downturn typically unveils ineffective and broken business processes. Organizations that once seemed agile and focused during periods of growth may become sluggish and inefficient when demand drops off.

Lastly, COVID-19 has expedited Digital Transformation for most organizations. One of the quickest and most impactful forms of Digital Transformation is Robotic Process Automation (RPA). Thus, we have included numerous RPA frameworks within this Stream.

Learn about our Process Improvement Best Practice Frameworks here.

Readers of This Article Are Interested in These Resources

22-slide PowerPoint presentation

Market pressures, technological disruption, and process related challenges adversely affect organizational performance, and force the organizations to rethink the way they do business. They end up implementing continuous process improvement or other innovation methodologies.

Continuous Process

[read more]

181-slide PowerPoint presentation

Total Quality Management (TQM) is a strategic approach that embeds a culture of continuous improvement across an organization. It goes beyond processes and outcomes, fostering a mindset where every function, system, and individual contributes to quality and excellence. By engaging all

[read more]

114-slide PowerPoint presentation

This document provides a collection of 100+ Key Performance Indicators (KPIs) related to the Operations functions listed further below.

Keeping in mind that each organization is different, the enclosed KPIs are intended as a general reference and their relevance depends on the specific

[read more]

46-slide PowerPoint presentation

The Lean Leader Green Belt Series are designed and developed specifically for Team Leaders and Supervisors. These series are at a higher standard than the shop floor series. When a staff member completes all the 12 modules he / she can be awarded a "Lean Leader" certificate and can lead

[read more]