Operational Excellence is an element of organizational leadership that stresses the application of a variety of principles, systems, and tools toward the sustainable improvement of key performance metrics.

Much of this management philosophy is based on earlier continuous improvement methodologies, such as Gemba Walk, Lean Manufacturing, and Kaizen. The focus of Operational Excellence goes beyond the traditional event-based model of improvement toward a long-term change in organizational culture. In this article, we have compiled a list of methodology documents centered around this. They were developed by a management consultancy appropriately named Operational Excellence Consulting.

Gemba Walk

https://flevy.com/browse/business-document/gemba-walk-543

In business, ‘Gemba’ refers to the place where value is created and improved. The ‘Gemba Walk’ is an activity that takes management to the front lines to look for waste (non-value added activities) and opportunities. The objective of Gemba Walk is to grasp the situation by involving everyone touching the process to understand the Purpose, Process, and People.

Lean Office

https://flevy.com/browse/business-document/lean-office-350

Lean Office is a management philosophy based on the Toyota Production System (TPS). With Lean Office, you will be able to enhance value for your customers by improving and smoothing the process flow and eliminating waste. Simply put, by becoming a Lean Office, you will be able to increase productivity and create greater customer value with less resources.

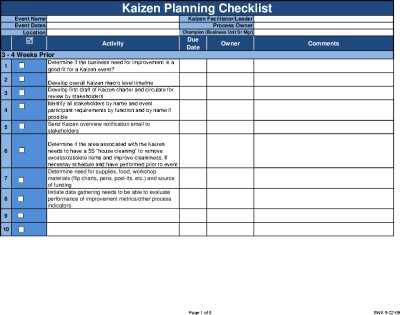

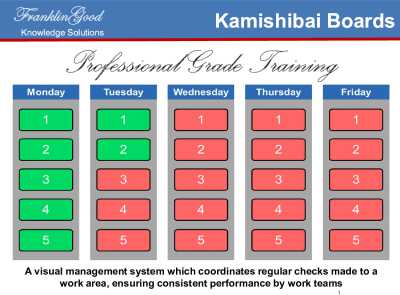

Kaizen

https://flevy.com/browse/business-document/kaizen-153

Kaizen strategy is the single most important concept in Japanese management – the key to successful Japanese companies such as Toyota. Kaizen, which simply means continuous improvement, is the foundation for all Lean improvements. Kaizen events are opportunities to make focused changes in the workplace.

Identifying Waste

https://flevy.com/browse/business-document/identifying-waste-618

All Lean production methods have the primary intention of improving manufacturing processes to bring increased profits to the manufacturer and increased value and satisfaction to the customer. To increase profits and delight the customer, you have to get rid of waste – all those extraneous assumptions, attitudes, activities, materials, machines, operations and processes.

5S for the Office

https://flevy.com/browse/business-document/5s-for-the-office-161

To become a Lean enterprise, office activities must fully support shop-floor manufacturing operations to eliminate waste. The adoption of 5S throughout all office functions is the first step to increase efficiency. The presentation covers 5S and Visual Management key concepts, best practices, step-by-step implementation guidance, and how to kick-start 5S in your organization.

In addition to these frameworks, Operational Excellence Consulting has 30+ similar documents on Flevy. View them here.

Do You Want to Implement Business Best Practices?

You can download in-depth presentations on Kaizen and 100s of management topics from the FlevyPro Library. FlevyPro is trusted and utilized by 1000s of management consultants and corporate executives.

For even more best practices available on Flevy, have a look at our top 100 lists:

- Top 100 in Strategy & Transformation

- Top 100 in Digital Transformation

- Top 100 in Operational Excellence

- Top 100 in Organization & Change

- Top 100 Management Consulting Frameworks

These best practices are of the same as those leveraged by top-tier management consulting firms, like McKinsey, BCG, Bain, and Accenture. Improve the growth and efficiency of your organization by utilizing these best practice frameworks, templates, and tools. Most were developed by seasoned executives and consultants with over 20+ years of experience.

Readers of This Article Are Interested in These Resources