Editor's Note: Take a look at our featured best practice, End-to-end (E2E) Operating Model Transformation (30-slide PowerPoint presentation). In many industries, executives have had their hands full staying competitive and surviving market downturns. This is done by making cuts, often silo by silo, and occasionally in ways that negatively affected customers.

It is time for organizations to rework their Operating Models in a new way, [read more]

Also, if you are interested in becoming an expert on Process Improvement, take a look at Flevy's Process Improvement Frameworks offering here. This is a curated collection of best practice frameworks based on the thought leadership of leading consulting firms, academics, and recognized subject matter experts. By learning and applying these concepts, you can you stay ahead of the curve. Full details here.

* * * *

Market pressures, technological disruption, and process related challenges adversely affect organizational performance, and force the organizations to continuously refine, reduce costs, and perform better. Eventually, they start exploring the possibilities of implementing continuous process improvement or other innovation methodologies.

Market pressures, technological disruption, and process related challenges adversely affect organizational performance, and force the organizations to continuously refine, reduce costs, and perform better. Eventually, they start exploring the possibilities of implementing continuous process improvement or other innovation methodologies.

Continuous Process Improvement (CPI) involves improving a product, service or process, either incrementally or revolutionally. However, process improvement isn’t a one-time engagement, rather, it runs continuously, necessitating the need to evolve constantly. CPI initiatives assist the executives analyze workplace systems and procedures, and transform those to improve efficiency and productivity. For instance, Business Process Re-engineering, Lean Six Sigma, and Theory of Constraints are all different methodologies to enable organized transformation and promote a culture of thinking and upgrading.

Likewise, Process Innovation assists the organizations in encouraging innovative thinking and ideas testing using prototyping and multiple rounds of validation. Through process innovation, organizations work out an existing problem or execute a business process in a unique way to enhance efficiency and performance. Creating completely different workflows for an existing production process that accelerates production—by saving organizational resources, e.g., money and time—is an example of process innovation. Process Innovation is distinct from Continuous Improvement, in that, it generates marked or game-changing improvement in value, sometimes in the range of 50 to 100%, or even more. Whereas continuous or incremental improvements generate limited value.

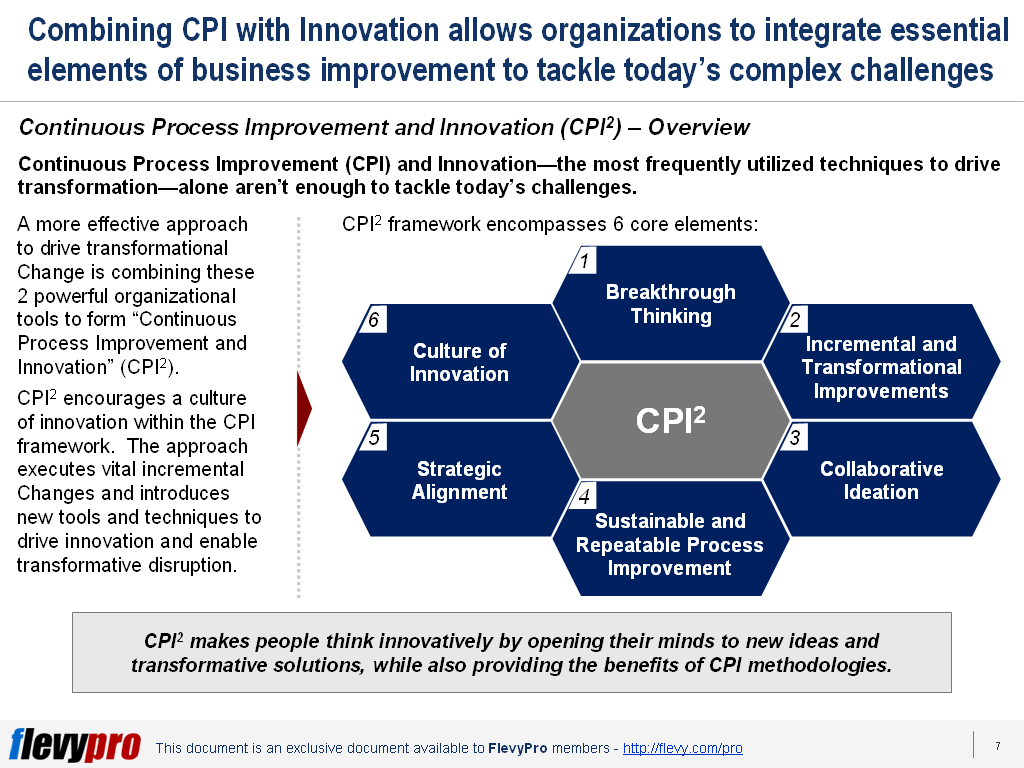

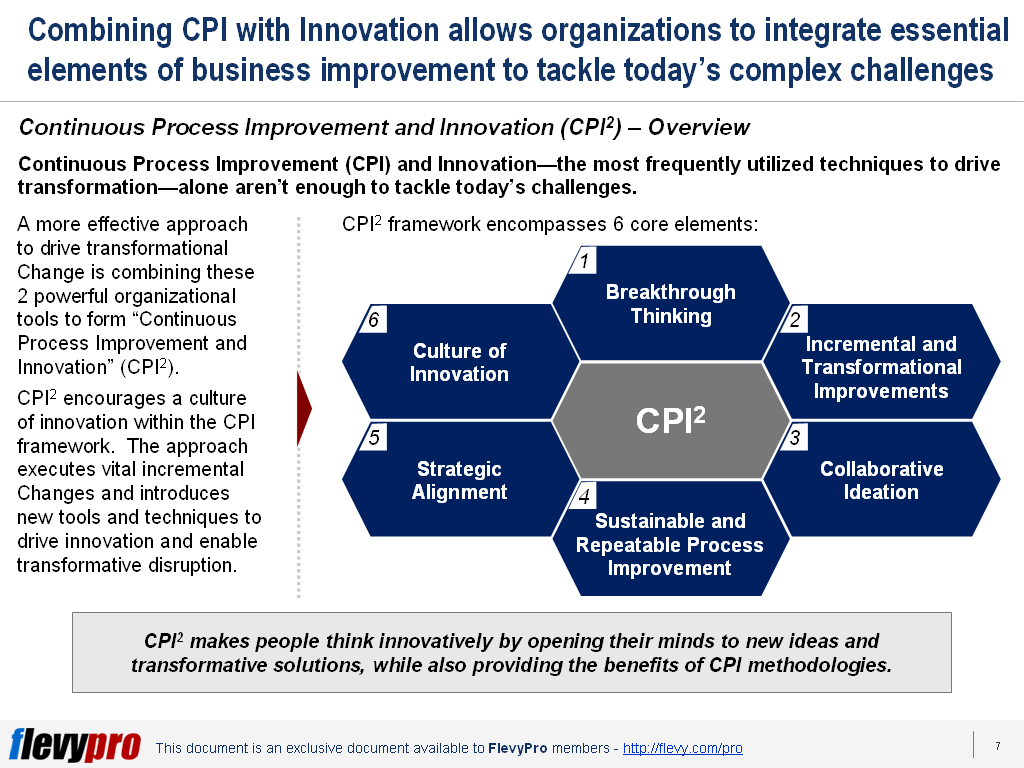

However, Continuous Process Improvement (CPI) and Innovation alone aren’t enough to tackle today’s challenges. A more effective approach to drive transformational change is combining these 2 powerful organizational tools in the form of “Continuous Process Improvement and Innovation” (CPI2). The CPI2 approach executes vital incremental changes and introduces new tools and techniques to drive innovation and enable transformative disruption. CPI2 framework encompasses 6 core elements that set organizations up for long-term success:

- Breakthrough Thinking

- Incremental and Transformational Improvements

- Collaborative Ideation

- Sustainable and Repeatable Process Improvement

- Strategic Alignment

- Culture of Innovation

By employing CPI2 companies can train their employees to think about problems differently and ingrain creativity needed to thrive in the evolving market. Implementing CPI2 facilitates in developing innovative ideas into change initiatives. This is achieved by executing sustainable process improvements—both incremental and transformational—engaging diverse teams to communicate with the entire value chain, and embedding an innovation culture in the organization.

The CPI2 approach perfectly blends Continuous Process Improvement tools and Innovation methodologies to assist the organizations analyze viable solutions and establish their strategic fit. Furthermore, the CPI2 framework helps nurture shared ideation among internal and external stakeholders—such as, leaders, employees, customers, and partners—and creates new organizational capabilities.

The CPI2 approach involves 4 phases of activity designed to discern and resolve organizational challenges:

- Define

- Discover

- Develop

- Deploy

Let’s now discuss the first 2 phases of the CPI2 approach.

Define

The first phase of CPI2 involves defining the scope of the challenge and recognizing opportunities to meet the requirements. During this stage, the senior leadership establishes and confirms the aspirations from the engagement. The program stakeholders, teams, and roles and responsibilities are outlined. Utilizing tools and techniques—such as Voice of the Customer and Maturity Assessment—the future state of the organization and success parameters are defined and agreed. The CPI2 Maturity Assessment assists in obtaining top management’s sponsorship for the engagement and steers team-based workgroups.

Discover

In the Discover phase, the CPI2 team embark on assessing and mapping the existing organizational practices, processes, and ways of doing business. They work towards setting up a problem solving ecosystem that empowers employees to control and improve the results of their work by incorporating customer experience, feedback, and needs. The team conducts quantitative and qualitative analysis of the “As-Is,” identifying any gaps and unfulfilled needs; and evaluate the environment, values, and experiences. By employing Innovation methodologies like “Crowd Sourcing”, the CPI2 team gathers information from process or service users, prioritize initiatives to improve critical areas, and line up people to develop solutions.

Interested in learning more about the phases of the Continuous Process Improvement and Innovation (CPI2) framework? You can download an editable PowerPoint on Continuous Process Improvement and Innovation (CPI2) here on the Flevy documents marketplace.

Are You a Management Consultant?

You can download this and hundreds of other consulting frameworks and consulting training guides from the FlevyPro library.

254-slide PowerPoint presentation

[NOTE: Our Kaizen presentation has been trusted by an array of prestigious organizations, including industry leaders such as Apple, Bayer, University of Michigan, General Motors, Cummins, Johnson Controls, Ulta, Daimler Truck, Aramark, Parsons Corporation, Minerals Technologies, Hunter Douglas, to

[read more]

Want to Achieve Excellence in Process Improvement?

Gain the knowledge and develop the expertise to become an expert in Process Improvement. Our frameworks are based on the thought leadership of leading consulting firms, academics, and recognized subject matter experts. Click here for full details.

Process Improvement involves analyzing and improving existing business processes in the pursuit of optimized performance. The goals are typically to continuously reduce costs, minimize errors, eliminate waste, improve productivity, and streamline activities.

As we continue to deal with COVID-19 and its economic aftermath, most organizations will prioritize Business Process Improvement initiatives. This is true for a few reasons. First, Process Improvement is one of the most common and effective ways of reducing costs. As the global economy slows down, Cost Management will jump to the forefront of most corporate agendas.

Secondly, a downturn typically unveils ineffective and broken business processes. Organizations that once seemed agile and focused during periods of growth may become sluggish and inefficient when demand drops off.

Lastly, COVID-19 has expedited Digital Transformation for most organizations. One of the quickest and most impactful forms of Digital Transformation is Robotic Process Automation (RPA). Thus, we have included numerous RPA frameworks within this Stream.

Learn about our Process Improvement Best Practice Frameworks here.

Readers of This Article Are Interested in These Resources

181-slide PowerPoint presentation

Total Quality Management (TQM) is a strategic approach that embeds a culture of continuous improvement across an organization. It goes beyond processes and outcomes, fostering a mindset where every function, system, and individual contributes to quality and excellence. By engaging all

[read more]

22-slide PowerPoint presentation

Market pressures, technological disruption, and process related challenges adversely affect organizational performance, and force the organizations to rethink the way they do business. They end up implementing continuous process improvement or other innovation methodologies.

Continuous Process

[read more]

114-slide PowerPoint presentation

This document provides a collection of 100+ Key Performance Indicators (KPIs) related to the Operations functions listed further below.

Keeping in mind that each organization is different, the enclosed KPIs are intended as a general reference and their relevance depends on the specific

[read more]

46-slide PowerPoint presentation

The Lean Leader Green Belt Series are designed and developed specifically for Team Leaders and Supervisors. These series are at a higher standard than the shop floor series. When a staff member completes all the 12 modules he / she can be awarded a "Lean Leader" certificate and can lead his team in

[read more]

Market pressures, technological disruption, and process related challenges adversely affect organizational performance, and force the organizations to continuously refine, reduce costs, and perform better. Eventually, they start exploring the possibilities of implementing continuous process improvement or other innovation methodologies.

Market pressures, technological disruption, and process related challenges adversely affect organizational performance, and force the organizations to continuously refine, reduce costs, and perform better. Eventually, they start exploring the possibilities of implementing continuous process improvement or other innovation methodologies.