Editor's Note: Take a look at our featured best practice, Supply Chain Sustainability (24-slide PowerPoint presentation). In the modern age, organizations are striving to form a sustainable Supply Chain system to cope with the challenges that are arising. Such issues include emission of hazardous substances, excessive resource consumption, Supply Chain risks, and complex procedures.

Organizations around the globe [read more]

Also, if you are interested in becoming an expert on Supply Chain Management (SCM), take a look at Flevy's Supply Chain Management (SCM) Frameworks offering here. This is a curated collection of best practice frameworks based on the thought leadership of leading consulting firms, academics, and recognized subject matter experts. By learning and applying these concepts, you can you stay ahead of the curve. Full details here.

* * * *

Even great products or services fail to save businesses if you don’t reach customers on time.

Even great products or services fail to save businesses if you don’t reach customers on time.

It is where supply chain activities come in.

Not that the industry always had the best of efficient supply chain systems.

There were always some “clouds of doubt” relating to its efficacy.

But the good part is, the advent of the “cloud” has shot up the performances of the supply chain activities.

No, it is a different cloud this time! We’re talking about Cloud Computing.

Cloud technology is on a phenomenal rise in enhancing the performances of key business areas.

The supply chain is one of the cloud’s most affected beneficiaries.

What Is Cloud Computing in the Supply Chain?

Cloud computing lets businesses take charge of data on remote servers rather than in-house servers.

Think of it as a common repository placed on the cloud, and everyone could get access to the supply chain network.

In a broader sense, Cloud Computing offers ways to optimize businesses with

- SaaS models

- Infrastructure

- Platform

- Software solutions for the supply chain network

- Operational and financial benefits

The supply chain involves many collaboration activities, the connection of resources, & coordination and communication at each network node.

SaaS models have been proved to ship cloud computing technology in the best way to such collaborative markets.

PAT Research forecasted the SaaS models for supply chain management should scale up by 24% in 2020.

Moreover, 57 percent of supply chain industry professionals already agree upon integrating cloud computing with supply chain operations in 2020.

So stats clarify that organizations have been taking advantage of cloud computing in solving supply chain inefficiencies.

If you’re looking to upgrade the S-C system, it’s best to turn to the professional consultants. They would integrate the system with cloud technologies and optimize the network for your business.

Where Do You Use Cloud Computing in the Supply Chain Department?

The supply chain has a list of activity components ranging from inventory to transportation or sources to information.

There’s no hardwired rule to using cloud computing in any specific activity. You can use the cloud to sharpen the components you like.

Here’s the list of activities most benefited with cloud computing:

- Forecasting and planning

- Logistics

- Services and spare parts management

- Sourcing and procurement

#1 Forecasting and planning

You want to forecast supply and demands to

- plan production and supply

- prevent future risk

Cloud computing

- lets you collect and unify data at one point, and

- allows you to apply needed analytics to predict and plan.

#2 Logistics

Mismanaged logistics like weak inventory systems & inefficient transport management are the weeds of the supply chain system.

They can pull down the best of the businesses.

Fortunately, cloud computing helps to stave off the logistics problems and optimizing:

- Transport route

- Operations tracking

- Inventory management

The unified data on the cloud eases the data flow and makes logistic planning simple.

#3 Services and spare part management

Services and spare part management can get tricky because they often go short. But Cloud computing

- keeps track of spare parts and orders them at the minimum level of availability.

- Predicts the time for automatic services and prevents downtime for the customers.

#4 Acquisition and procurement

You must order supplies with the suppliers and procure materials on time.

Many businesses fail to acquire materials from suitable sources solely because they lack information.

Cloud platforms pool master database that includes best prices, sources, and optimal date of the transaction to be made.

You can automate the buying process for procurement so the supply chain network orders from the best supplier if you reach a minimal level.

What Are the Benefits of Cloud Technologies in Supply Chain Management?

Though the transition from a traditional S-C management system to a cloud-based management system may feel challenging to you, its benefits outweigh migration hassle.

Have a look at some of them:

Benefit #1: You have a birds-eye view of data in real-time

These days, plenty of business actions take place in the background every minute.

You can quickly lose sight of information with such overloaded actions.

Cloud computing keeps you informed with supply chain actions in real-time and helps improve your plans accordingly.

Benefit #2: You can upscale or downscale anytime

Whether your customer base grows or your supply chain system needs to be upgraded; cloud computing can get you there without overhauling the entire system.

The off-site computing power can scale you up or down much faster than you can plan and execute it yourself.

Benefit #3: You may get the supply chain upgraded immediately

Immediacy is the key to cloud computing.

You’re not gathering resources and planning execution yourself. The set-up is already stacked-up.

All you really need to do is get in touch with professional cloud-backed supply chain management providers and see yourself up and running quickly.

Benefit #4: It’s cost-efficient for you

Imagine the cost you save from supply chain mishaps.

A non-efficient bottleneck chain can cost you clients and businesses.

But cloud-based supply management systems come cheaper to you with minimal downtime.

You only need to subscribe rather than investing in the resources yourself and fend off the logistics and inventory mishaps from happening.

The Conclusive Argument

The bottom line is— if you’re on a collaborative network, everyone should be able to share data smoothly without adding to the silo stress.

Cloud computing can handle thousands of supply chain actions at any given point in time without you having to suffer from data overloading.

Want to Achieve Excellence in Supply Chain Management (SCM)?

Gain the knowledge and develop the expertise to become an expert in Supply Chain Management (SCM). Our frameworks are based on the thought leadership of leading consulting firms, academics, and recognized subject matter experts. Click here for full details.

Supply Chain Management (SCM) is the design, planning, execution, control, and monitoring of Supply Chain activities. It also captures the management of the flow of goods and services.

In February of 2020, COVID-19 disrupted—and in many cases halted—global Supply Chains, revealing just how fragile they have become. By April, many countries experienced declines of over 40% in domestic and international trade.

COVID-19 has likewise changed how Supply Chain Executives approach and think about SCM. In the pre-COVID-19 era of globalization, the objective was to be Lean and Cost-effective. In the post-COVID-19 world, companies must now focus on making their Supply Chains Resilient, Agile, and Smart. Additional trends include Digitization, Sustainability, and Manufacturing Reshoring.

Learn about our Supply Chain Management (SCM) Best Practice Frameworks here.

Readers of This Article Are Interested in These Resources

67-slide PowerPoint presentation

This deck was developed to support supply chain visioning and strategic diagnostics. It provides checklists of key questions to ask in formulating a supply chain strategy, core frameworks, tools and techniques that facilitate the strategic thinking process.

See also "Supply Chain Performance and

[read more]

27-slide PowerPoint presentation

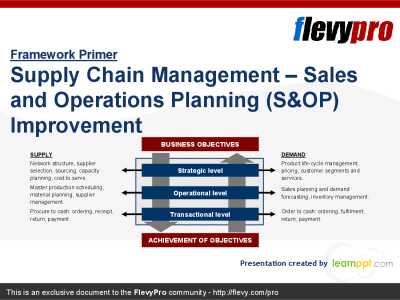

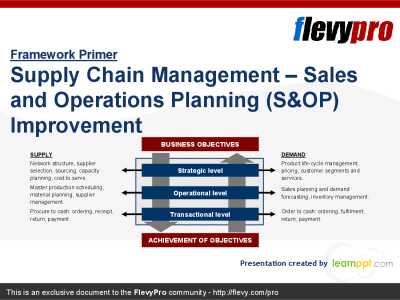

Today's competitive global markets necessitate a strong attention on Supply Chain Management and the underlying Sales & Operations Planning (S&OP) process. Shorter product life cycles, unstable demand, and international supply chains yield planning even more difficult.

This presentations

[read more]

113-slide PowerPoint presentation

This document provides a collection of 100+ Key Performance Indicators (KPIs) related to the Supply Chain functions listed further below.

Keeping in mind that each organization is different, the enclosed KPIs are intended as a general reference and their relevance depends on the specific

[read more]

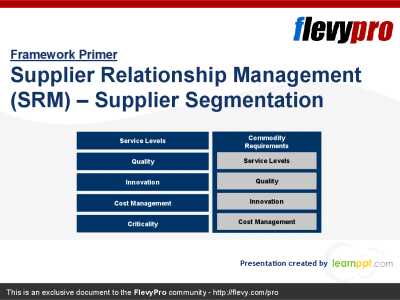

24-slide PowerPoint presentation

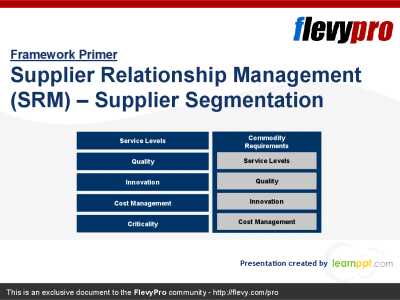

Competition has forced industries to converge on efficiency. Most of them have recognized that they must investigate all potential levers for creating value. As a result, they are actively pursuing collaboration across the supply chain.

Supplier segmentation is one of the foremost lever that

[read more]

Even great products or services fail to save businesses if you don’t reach customers on time.

Even great products or services fail to save businesses if you don’t reach customers on time.