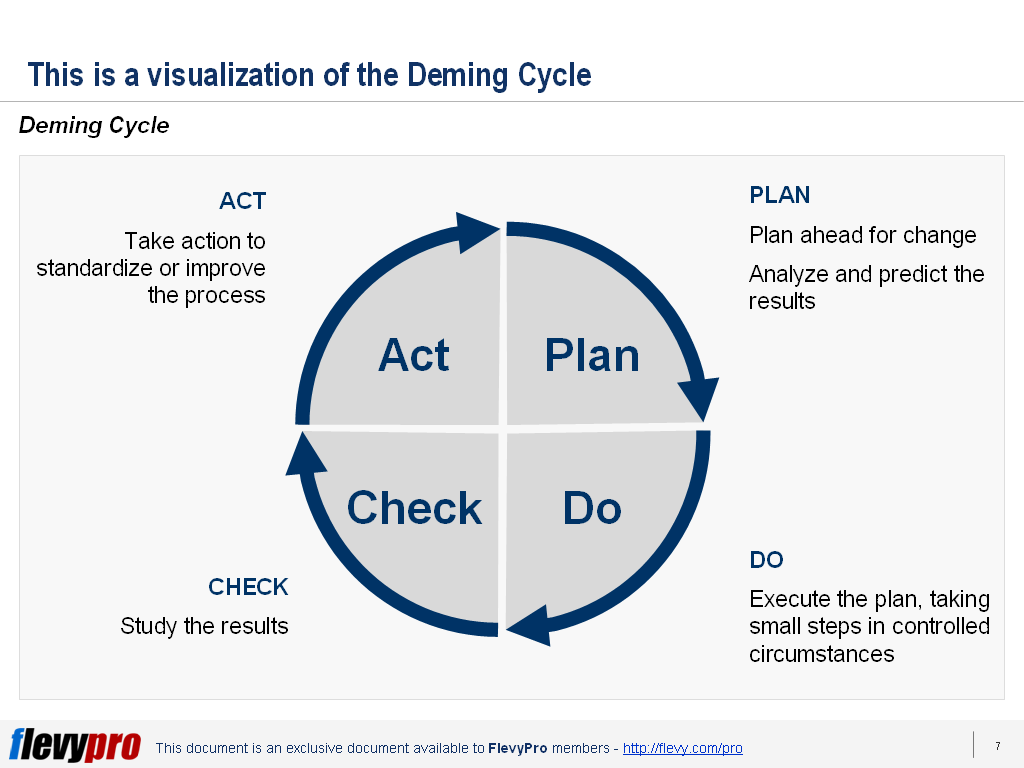

Continuous Improvement 101: The Deming Cycle (PDCA)

“Continuous Improvement” is a term management consulting firms love using. It’s also a driving principle behind Lean Management. So, how can we achieve Continuous Improvement in our organization? One of the most common Lean frameworks… Continuous Improvement 101: The Deming Cycle (PDCA)