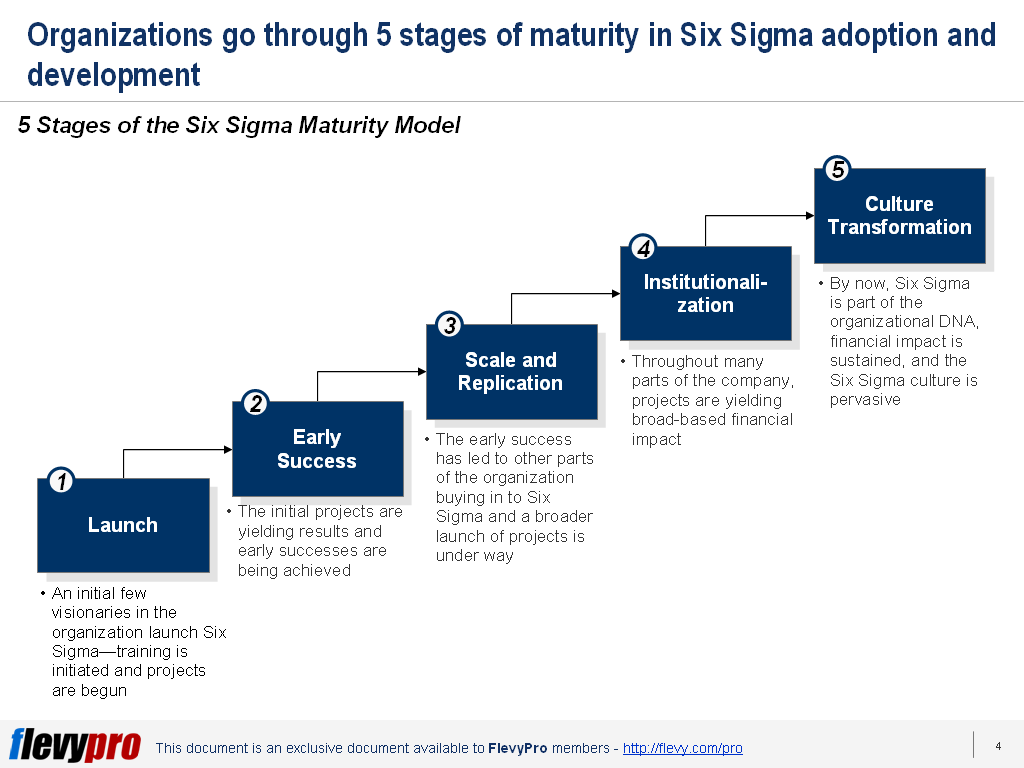

Are You Finding It Difficult to Deploy Six Sigma?

As the case with all management models, the theory may come easily, but execution can be tough. The same goes with Six Sigma. To assist with Six Sigma deployment, follow the Six Sigma Maturity Model. The… Are You Finding It Difficult to Deploy Six Sigma?