Robotics now stretches from warehouse aisles to surgical suites to last fifty meters delivery. Capital keeps flowing because robots shift cost curves and improve safety while unlocking speed that manual processes just cannot sustain.

McKinsey Global Institute has estimated that roughly half of current work activities are technically automatable with today’s tech, which tells you the ceiling remains high even after a decade of progress. Demand feels cyclical, yet the long arc points to more autonomy, better sensors, and tighter links between software and hardware.

A robust value chain matters because growth dies when integration wobbles. Customers do not buy a robot, they buy a reliable outcome at a predictable cost over the full life. Miss on any hand off and margins leak faster than you can say root cause analysis. Leaders wire design, supply, and service into one rhythm so prototypes become scalable products without drama.

Robotics Value Chain Fundamentals and the Moving Parts

A value chain is the connected system that turns ideas into fielded robots into lifecycle cash. The robotics version spans research, design, core components, intelligence, and the gritty last mile of deployment and service. Think choreography, not a linear pipeline. The win comes when each node reduces friction for the next team and raises confidence for the customer.

The Robotics Value Chain includes:

Primary activities

- Market & Application Research

- Concept & System Design

- Component Engineering & Manufacturing

- Software & Algorithm Development

- System Integration & Assembly

- Testing, Validation & Certification

- Sales, Deployment & Installation

- After Sales Support & Lifecycle Services

Support activities

- Research Partnerships & Open Innovation

- Supply Chain & Vendor Management

- Quality & Regulatory Compliance

- Information Technology & Data Infrastructure

- Human Capital Management

- Finance & Investor Relations

- Marketing & Brand Management

- Sustainability & Risk Management

Download an in-depth presentation breaking down all the Robotics Value Chain activities here.

Where the Project Is Won on the Floor

System Integration & Assembly

Integration converts parts into performance. Teams orchestrate compute, power, sensors, actuators, and communications while managing thermal, weight, and cost constraints that never seem to agree with each other. Great integrators design for test from day one, use simulation to pre validate behavior, and standardize interfaces to swap suppliers without a forklift rewrite. The best lines instrument everything, from torque signatures on critical joints to calibration drift, and push that data back to design weekly. Margins rise when takt time, yield, and software flash success all trend in the right direction with no heroics.

After Sales Support & Lifecycle Services

Lifecycle services now hold a growing slice of profit pools. Predictive maintenance, software updates, remote troubleshooting, and consumables management anchor the relationship and smooth cash through downturns. Winning organizations treat installed base data like gold, building health scores, churn flags, and parts risk models that drive proactive outreach. Service teams need clear entitlement rules and tight links into engineering so field learnings actually shorten the bug backlog. Customers forgive the odd hiccup. They do not forgive radio silence.

Innovation that Actually Pays Its Way

Simulation and digital twins shorten iteration cycles and de risk deployments. Teams that combine physics engines with synthetic data generation train perception stacks faster and arrive on site with tuned behaviors rather than science projects. A twin that mirrors the line or warehouse lets you trial routing logic and human interactions without stopping production. That looks boring to outsiders. Your schedule loves it.

Modularity is back in fashion and for good reason. Common compute boards, standardized sensor bays, and reusable motion stacks cut redesign time and broaden supplier choice. Price pressure hit more than one segment, so swappable modules let you deliver a premium trim and a value trim without rewriting control software every quarter. Customers read this as faster feature velocity, which quietly raises win rate.

Edge AI is moving from experiment to routine. Better on board acceleration and clever compression let robots run richer models with lower latency while keeping privacy sensitive data local. Perception gets more robust in messy environments and safety zones adapt dynamically to real world behavior. Teams should maintain a tight MLOps loop for datasets, labeling quality, drift monitoring, and rollback plans. That discipline looks unglamorous and completely pays off.

Business model innovation matters as much as tech. Robotics as a service aligns cash flows with value delivered and lowers adoption friction for cautious buyers. Contract structures that peg fees to uptime, picks per hour, or units processed create skin in the game on both sides. McKinsey has shown automation can add meaningful productivity growth for economies, roughly one percent per year, which gives finance leaders comfort to back models that scale with usage rather than only unit sales.

Rules that Build Trust and Keep You Shipping

Safety and functional safety sit at the core. Standards like ISO 10218 for industrial robots and ISO 13849 for safety related parts of control systems shape design, validation, and documentation. Certification artifacts must be treated as product features, not afterthoughts, because buyers will audit them. Cybersecurity needs equal attention as robots connect to enterprise IT and cloud services. Secure boot, signed updates, and network segmentation are table stakes.

Regulators are raising the bar on AI inside robotic systems. The EU AI Act introduces obligations for high risk systems including risk management, data governance, and post market monitoring. Teams should map each algorithm to intended use, document training datasets, and maintain event logs that support forensic review. That lowers regulatory risk and speeds customer approvals because your evidence package is ready on day one.

Sector rules add extra layers. Medical robotics face quality system expectations under ISO 13485 and premarket clearance pathways that demand clinical and usability evidence. Food and pharma settings add GMP constraints that ripple into material selections and cleanability. Warehouse and manufacturing deployments must align with local machine directives and worker safety rules that vary more than you expect, often by region inside the same country. Compliance leaders who speak the language of operations win internal trust.

Supply chain transparency is now strategic. Ethics questions around certain minerals, lithium battery transport and testing, and country of origin are moving into contracts. Vendor scorecards that track audit coverage, corrective actions, and tier two visibility reduce surprises. Sustainability reporting asks for product level data on energy and emissions, which requires meters on your own lines and credible models for supplier processes. No one enjoys the spreadsheet wrangling. Your next RFP will silently reward it.

Your Board Level FAQ

Where should we place the next large bet, software or hardware.

Invest where you remove friction for integration and service. Software and data platforms that unify perception, control, and fleet management usually create more reuse and faster gross margin lift.

How aggressive should we go on robotics as a service.

Pilot where reliability is proven and usage is trackable. Protect unit economics with clear uptime definitions, spare pools, and step down clauses if environments change.

What is the fastest path to improve deployment velocity.

Create pre engineered reference cells and playbooks by use case. Pair them with customer readiness checklists so facility changes, IT hooks, and safety validations happen before trucks roll.

Which KPIs belong on the executive dashboard.

Yield through final test, first thirty day failure rate, integration cycle time, software defect escape rate, service response time, and revenue mix from recurring sources. Add crew retention for both factory technicians and field engineers.

How do we avoid vendor lock on critical components.

Standardize electrical and data interfaces, qualify at least two suppliers per class, and maintain adaptor boards as insurance. Track last time buy dates and keep a rolling redesign plan for obsolete parts.

What is our realistic AI roadmap inside the robot.

Focus on perception robustness and simple planning wins first. Layer in advanced models only when your data engine and rollback controls can support them without drama.

How do we scale internationally without compliance headaches.

Build a core evidence package once, then map deltas for each region. Use internal auditors who travel with deployment teams for the first wave so lessons feed back quickly.

Where does sustainability create margin instead of only cost.

Energy monitoring and smart power profiles reduce operating cost on site. Design for repair and module reuse lowers your service costs and improves win rate with buyers tracking emissions.

Closing Thoughts from the Lab Bench

Robotics rewards organizations that love feedback loops. Engineers who watch service tickets, service leads who sit in design reviews, and product managers who review yield data each Friday create a culture that learns faster than competitors do. The surprising part is how much of this is process discipline, not breakthrough math, although the math still matters a lot.

Ask one blunt question at your next leadership check in. Where in our value chain do we create trust and where do we leak it. Fix one leak per quarter with visible owners and measurable outcomes, then publicize those wins internally. Teams will copy the habit and your roadmap will suddenly feel lighter. McKinsey’s long standing point about automation driven productivity growth becomes personal when your own operation starts to move that way.

Do You Want to Implement Business Best Practices?

You can download in-depth presentations on Automation and 100s of management topics from the FlevyPro Library. FlevyPro is trusted and utilized by 1000s of management consultants and corporate executives.

For even more best practices available on Flevy, have a look at our top 100 lists:

These best practices are of the same as those leveraged by top-tier management consulting firms, like McKinsey, BCG, Bain, and Accenture. Improve the growth and efficiency of your organization by utilizing these best practice frameworks, templates, and tools. Most were developed by seasoned executives and consultants with over 20+ years of experience.

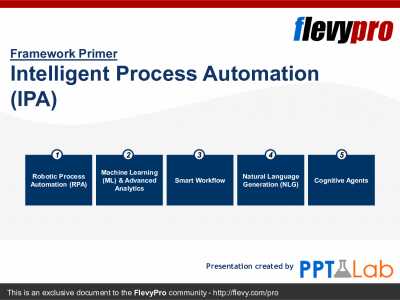

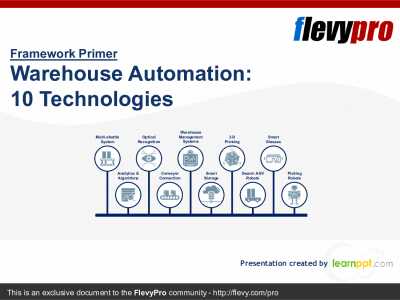

Readers of This Article Are Interested in These Resources

26-slide PowerPoint presentation

Shortage of labor, intensified demand from e-tailers (online retailers), and technological disruption is forcing many organizations in the Logistics and Warehousing sectors to embrace technology, particularly Automation.

Automation is facilitating Warehouse operations predominantly by

[read more]

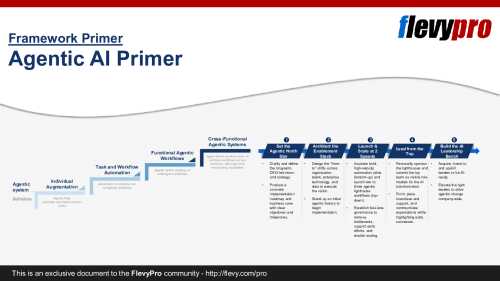

32-slide PowerPoint presentation

Agentic AI addresses a critical challenge in enterprise adoption: while most organizations achieve early success with individual models, few connect them into cohesive systems that transform business performance.

Traditional automation improves efficiency, yet it rarely redefines how decisions

[read more]

20-slide PowerPoint presentation

Technology has promoted every industry and occupation. Marketing has been one such function where scores of firms are now leveraging technological advancement to personalize marketing or bring efficiency in their advertisement expenditure--leading to the rise of Marketing Automation.

With more

[read more]

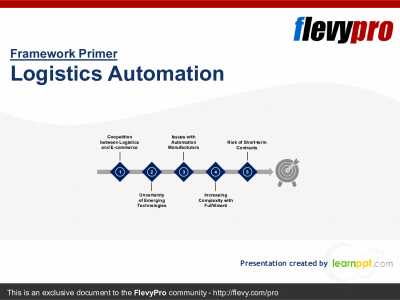

28-slide PowerPoint presentation

Automation is disrupting the entire Logistics Supply Chain, not just the warehousing, picking, and sorting functions. The impact of Automation on roads, rails, and ports is immense. Automation is assisting in reducing operating expenses of ports by 15 to 35%, yet output is diminishing by 7 to

[read more]