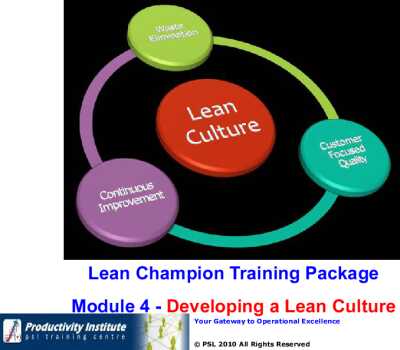

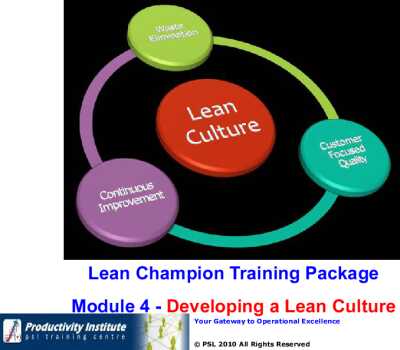

Editor's Note: Take a look at our featured best practice, Developing a Lean Culture (46-slide PowerPoint presentation). This presentation has 46 slides and consists of:

What is culture and definitions

What is organisational culture?

How to develop OC

Leaders & Leadership

Great leaders strategies

Developing a culture statement

Employee engagement

Organisational alignment

Also included with this [read more]

Also, if you are interested in becoming an expert on Organizational Culture (OC), take a look at Flevy's Organizational Culture (OC) Frameworks offering here. This is a curated collection of best practice frameworks based on the thought leadership of leading consulting firms, academics, and recognized subject matter experts. By learning and applying these concepts, you can you stay ahead of the curve. Full details here.

* * * *

Lean Management has been an area of increasing interest for Flevy customers. As of now, we have over 300 documents related to various Lean concepts and Vishnu Rayapeddi contributed close to 100 of these documents–with a focus on training series. Vishnu is a pioneer of Lean Management, combining the power of Lean Thinking, Six Sigma, Balanced Scorecard, and other best-class methodologies, like Standard Work, JIT, and Kanban. He ran a training institution focused on teaching people Lean for a decade and, during this time, interacted with many world-renown Lean experts. Most of the documents used by his training institution are now available on Flevy.

Lean Management has been an area of increasing interest for Flevy customers. As of now, we have over 300 documents related to various Lean concepts and Vishnu Rayapeddi contributed close to 100 of these documents–with a focus on training series. Vishnu is a pioneer of Lean Management, combining the power of Lean Thinking, Six Sigma, Balanced Scorecard, and other best-class methodologies, like Standard Work, JIT, and Kanban. He ran a training institution focused on teaching people Lean for a decade and, during this time, interacted with many world-renown Lean experts. Most of the documents used by his training institution are now available on Flevy.

In this interview with Vishnu, we learn not only more about his background and experience in Lean, but better understand the applications of Lean and challenges of its implementation.

People in the field recognize you as a pioneer in Lean Management. Can you tell us a bit more?

Sure, I have been involved in continuous improvement for nearly 30 years and this started with a project on inventory management when I was an undergraduate in 1985, where I showed over INR 450,000 savings. I never looked back since then. Wherever I worked, I always used to look for improvement opportunities. Without knowing the word “lean,” I have implemented a number of Lean concepts over the years, such as 5S, Visual Systems, Standard Work, Kanban, Set-up reduction, and others. Lean is nothing but a common sense approach to me. But, unfortunately how common is common sense?

How long have you been training people in Lean?

As a Lean coach and consultant, for over 8 years, when I started Productivity Solutions Limited. But, before that, I have trained my team members for about 12 years or so.

You have a number of Lean training series and work presentations made available on Flevy. Which of your products would you recommend to someone who has a basic understanding of Lean, but wants to become an expert on the topic?

If a person has basic understanding of Lean, I would suggest the Lean Leader Series, which is similar to Green Belt in Six Sigma.

You sponsored a talk by Dr. Jeffrey Liker, author of “The Toyota Way” in New Zealand. What were some key takeaways from his workshop?

I would say that the first thing is “humility.” Every lean practitioner, by virtue of being a Lean Sensei, needs to be humble and modest in his or her approach.

Now, coming to the workshop takeaways, there are many. But some of these are: first, The Toyota Way Philosophy, how Toyota runs its business, based on the long term approach even at the cost of short term by focusing on “True North.” Second, the way Toyota treats its people, even in the times of recession. Many staff were retrained during the global financial crisis, rather than making lay offs. Third, the way Toyota respects its staff. Every staff member is trained in the scientific problem solving methodology using PDCA (Plan-Do-Check-Act) cycle and is given an opportunity to participate in projects to improve further

Has becoming a Lean practitioner affected the way you approach situations that arise outside the workplace?

Sure, it did. I see most situations and analyse them thoroughly before coming to conclusions. Also, I use the “continuous improvement” concept in my personal situations.

Can Lean principles be applied to any industry?

Yes, definitely. Lean is a set of principles and practices and can be applied to any industry. The trick is to ensure that the application of Lean is in line with the needs and requirements of a particular situation. i.e., one needs to pick and choose the tools which can be used in a specific industry sector. Apart from the tools, the long-term philosophy, focusing on true north, respecting people, problem solving methodology, etc. are applicable to every industry.

Can Lean be applied to any size organization?

Once again, yes. But, rather than rolling out Lean throughout the organisation in one go, it is advisable to implement it at one plant or site at a time and take the learning’s to another plant or site.

What’s the biggest challenge to implementing Lean?

In my experience, the biggest challenge is the “commitment” from the top management. When I say commitment, it’s not just about signing the checks or providing financial resources for Lean implementation. Lean is all about culture change. To bring about a culture change, the senior and top management should take part in the improvement projects, even if it is for a short duration. This is to emphasize to the front line staff that the senior management is committed to making it happen and Lean is not just for the shop floor staff–and it applies to everyone.

5-page Word document

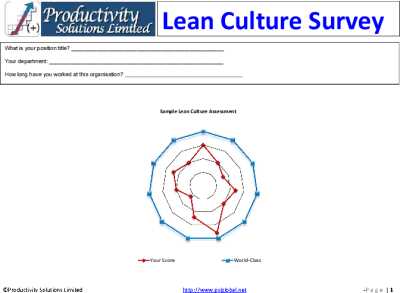

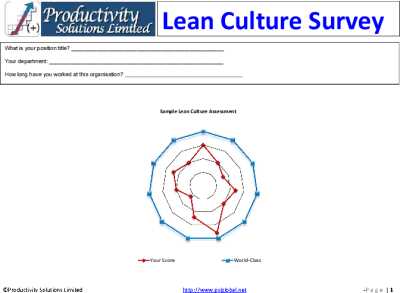

This checklist has 48 questions which you can rate on a 1 to 5 scale to understand the current culture of your organisation and set goals for improvement.

It focuses on the following:

Purpose, Values, Urgency, Trust, Competence, Customer Focus,Systems, Structure, Score Keeping and

[read more]

Want to Achieve Excellence in Organizational Culture (OC)?

Gain the knowledge and develop the expertise to become an expert in Organizational Culture (OC). Our frameworks are based on the thought leadership of leading consulting firms, academics, and recognized subject matter experts. Click here for full details.

Organizational Culture, also referred to as Corporate Culture or Company Culture, is the set of underlying and shared beliefs, vision, assumptions, values, habits, business philosophies, and ways of interacting that contribute to the unique social and psychological environment of the organization.

Organizational Culture permeates the organization, affecting all functions and all levels. It starts with what employees do and how they do it—and ultimately drives why employees do what they do. Culture is like the DNA of the organization.

That is why a healthy Company Culture leads to strong Performance, Growth, and Excellence—and the opposite is also true. For any initiative to be successful, we need a Corporate Culture that inherently supports that initiative.

Learn about our Organizational Culture (OC) Best Practice Frameworks here.

Readers of This Article Are Interested in These Resources

27-slide PowerPoint presentation

Organizational Culture is essential today in helping employees and management survive in today's environment. Survival has become a strong word today. Without Culture, everyone in the organization would act or behave differently. No one would be able to anticipate someone else's behavior, and no

[read more]

46-slide PowerPoint presentation

The Lean Champion Black Belt Series are designed and developed specifically for Manager and above roles. These series are at the highest standard among the enterprise series. When a person completes all the 15 modules he / she can be awarded a "Lean Champion" certificate which is equivalent to a

[read more]

Excel workbook

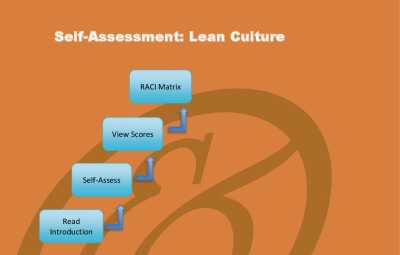

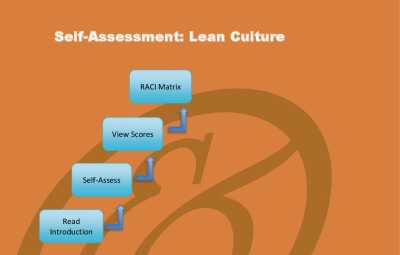

The Lean Culture Self-Assessment will make you a Lean Culture domain expert by:

Reducing the effort in the Lean Culture work to be done to get problems solved

Ensuring that plans of action include every Lean Culture task and that every Lean Culture outcome is in place

Saving time

[read more]

Lean Management has been an area of increasing interest for Flevy customers. As of now, we have over 300 documents related to various Lean concepts and

Lean Management has been an area of increasing interest for Flevy customers. As of now, we have over 300 documents related to various Lean concepts and