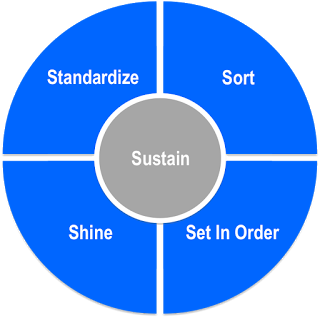

Eliminate Non-Value Added Activities in Your Organization

Regardless of economic conditions–recession or boom–organizations must continuously sharpen their competitive edge. This can be achieved through Lean Management principles focused on Cost Reduction, specifically targeting the elimination of non-value-added (NVA) activities or waste within… Eliminate Non-Value Added Activities in Your Organization