Editor's Note: Take a look at our featured best practice, Warehouse Automation: 10 Technologies (26-slide PowerPoint presentation). Shortage of labor, intensified demand from e-tailers (online retailers), and technological disruption is forcing many organizations in the Logistics and Warehousing sectors to embrace technology, particularly Automation.

Automation is facilitating Warehouse operations predominantly by [read more]

Also, if you are interested in becoming an expert on Supply Chain Management (SCM), take a look at Flevy's Supply Chain Management (SCM) Frameworks offering here. This is a curated collection of best practice frameworks based on the thought leadership of leading consulting firms, academics, and recognized subject matter experts. By learning and applying these concepts, you can you stay ahead of the curve. Full details here.

* * * *

Shortage of labor, intensified demand from e-tailers (online retailers), and technological disruption is forcing organizations in the Logistics and Warehousing industry to embrace technology, particularly Automation.

Shortage of labor, intensified demand from e-tailers (online retailers), and technological disruption is forcing organizations in the Logistics and Warehousing industry to embrace technology, particularly Automation.

An investment in automating the picking, packing, sorting, storing, and shipping items can yield high returns for organizations. Warehouses that will sort out the dynamics of e-commerce, select the ideal technology to implement, and eliminate uncertainties in their supplier contracts will outpace others.

Automation is facilitating the Warehousing operations predominantly by:

- Assisting the movement of goods.

- Improving the handling of goods.

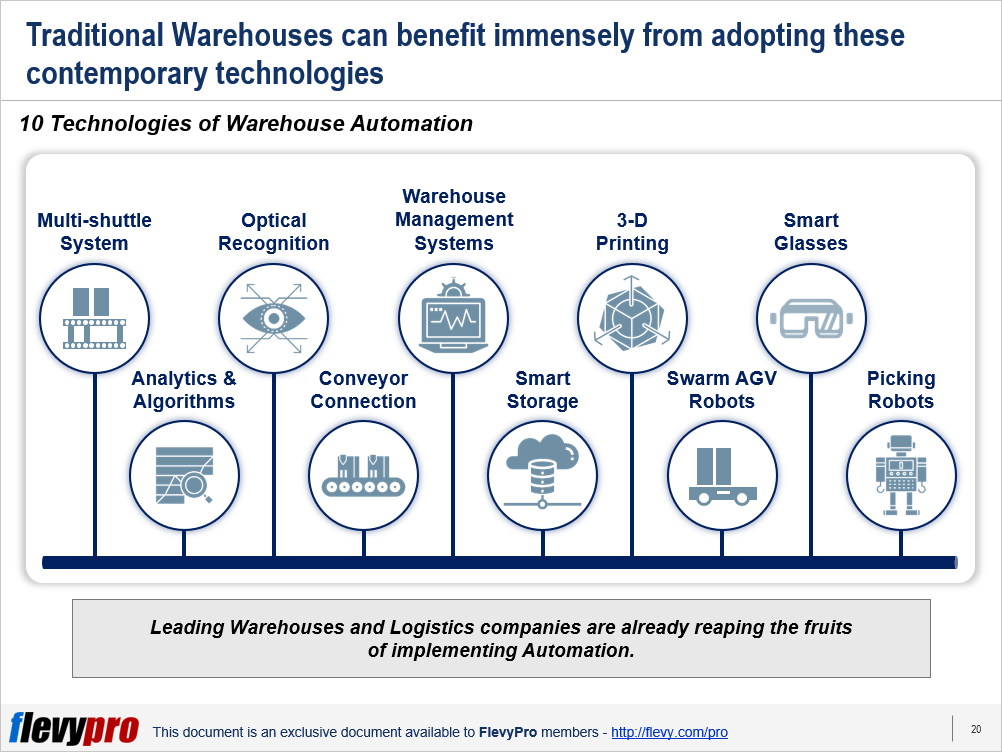

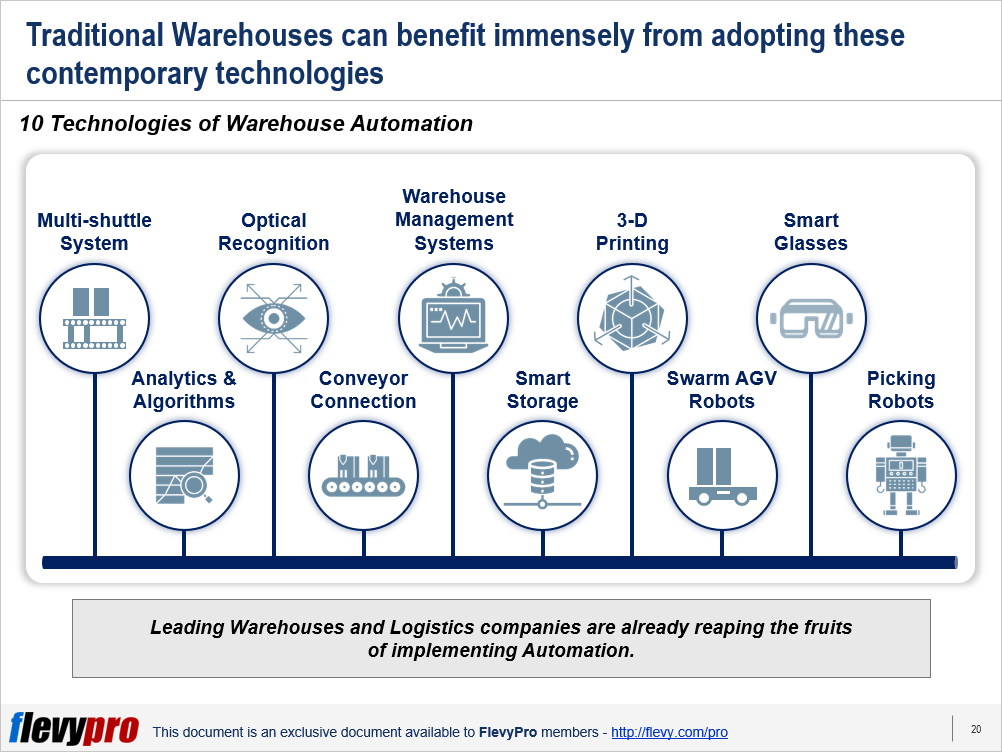

In these two categories, there are 10 technologies that are fast disrupting the Supply Chain function and creating a breakthrough for warehouses. These include:

- Multi-shuttle System

- Optical Recognition

- Conveyor Connection

- Warehouse Management Systems

- Smart Storage

- 3D Printing

- Swarm AGV Robots

- Analytics & Algorithms

- Smart Glasses

- Picking Robots

Let’s discuss a few of these disruptive technologies in detail.

Multi-shuttle System

Multi-shuttle systems (MSS) are employed to store and retrieve goods automatically—using automated storage and retrieval system (AS/RS). This system is able to transport goods 3 dimensionally (on pallets), and is instrumental in enhancing the throughput, flexibility and efficiency levels.

MSS consists of 3 modules, coordinated by a software module: a Shuttle car powered by power caps for 24-hour operations and moved by powerful motors, high-performance vertical lifts, and a special carrier to move the shuttle car to the exact location. Communication in the multilevel systems’ carrier and shuttles is managed by radio links, whereas the movement is controlled by an integrated control system.

Multilevel Shuttle Storage System is ideal for cold storage, buffer storage, dispatching warehouses, commissioning warehouses, supply and distribution centers, and factories.

MSS offers a number of benefits, e.g.:

- High item storage and retrieval velocity.

- Optimum use of building space.

- High storage density.

- Ability to be retrofitted in existing warehouses.

Optical Recognition

Optical Recognition and Sensor technology expedites processes and increases productivity. This technology is at the foundation of IoT, smart cities, automobiles and laser-guided vehicles, smartphones, wearable technologies, drones, barcode readers, and more.

Optical Recognition devices use a light source to read characters and barcodes. They then convert these characters into digital data. Optical Recognition devices scan items. At times, this scanning is done on 6 axes. The character recognition software then relates this image to the shapes of individual characters.

Optical recognition devices today use sensors to detect and respond to a specified input—light, sound, motion, pressure, temperature. Once an input is received, a sensor either produces a resulting output—in the form of a light or alarm—or forward the information received to a network for processing.

Optical recognition sensors facilitate in:

- Accelerating and improving processes, inspecting parts for error checking, and quality monitoring.

- Delivering real-time data to make better decisions.

- Handling repetitive and hazardous tasks and making workplaces safer

- Freeing up people to manage more complex endeavors.

- Slashing energy wastage and creating connected, smart factories.

Conveyor Connection

Connected Conveyor Systems are useful in transporting heavy or bulky materials. These systems allow quick and efficient transport of a variety of materials (e.g. totes, cartons) in different warehouse configurations. Advanced conveyor systems and connections perform various material handling requirements including accumulation, transportation, diverting, merging, and sorting products.

Interested in learning more about the other technologies reshaping the warehousing operations? You can download an editable PowerPoint presentation on Warehouse Automation: 10 Technologies here on the Flevy documents marketplace.

Do You Find Value in This Framework?

You can download in-depth presentations on this and hundreds of similar business frameworks from the FlevyPro Library. FlevyPro is trusted and utilized by 1000s of management consultants and corporate executives. Here’s what some have to say:

“My FlevyPro subscription provides me with the most popular frameworks and decks in demand in today’s market. They not only augment my existing consulting and coaching offerings and delivery, but also keep me abreast of the latest trends, inspire new products and service offerings for my practice, and educate me in a fraction of the time and money of other solutions. I strongly recommend FlevyPro to any consultant serious about success.”

– Bill Branson, Founder at Strategic Business Architects

“As a niche strategic consulting firm, Flevy and FlevyPro frameworks and documents are an on-going reference to help us structure our findings and recommendations to our clients as well as improve their clarity, strength, and visual power. For us, it is an invaluable resource to increase our impact and value.”

– David Coloma, Consulting Area Manager at Cynertia Consulting

“As a small business owner, the resource material available from FlevyPro has proven to be invaluable. The ability to search for material on demand based our project events and client requirements was great for me and proved very beneficial to my clients. Importantly, being able to easily edit and tailor the material for specific purposes helped us to make presentations, knowledge sharing, and toolkit development, which formed part of the overall program collateral. While FlevyPro contains resource material that any consultancy, project or delivery firm must have, it is an essential part of a small firm or independent consultant’s toolbox.”

– Michael Duff, Managing Director at Change Strategy (UK)

33-slide PowerPoint presentation

Companies are constantly looking to improve efficiency and reduce costs. One area that has a significant potential for achieving both is the Supply Chain.

Companies generally neglect Supply Chain simply because they do not consider it their core competency. Warehousing and Transportation in

[read more]

Want to Achieve Excellence in Supply Chain Management (SCM)?

Gain the knowledge and develop the expertise to become an expert in Supply Chain Management (SCM). Our frameworks are based on the thought leadership of leading consulting firms, academics, and recognized subject matter experts. Click here for full details.

Supply Chain Management (SCM) is the design, planning, execution, control, and monitoring of Supply Chain activities. It also captures the management of the flow of goods and services.

In February of 2020, COVID-19 disrupted—and in many cases halted—global Supply Chains, revealing just how fragile they have become. By April, many countries experienced declines of over 40% in domestic and international trade.

COVID-19 has likewise changed how Supply Chain Executives approach and think about SCM. In the pre-COVID-19 era of globalization, the objective was to be Lean and Cost-effective. In the post-COVID-19 world, companies must now focus on making their Supply Chains Resilient, Agile, and Smart. Additional trends include Digitization, Sustainability, and Manufacturing Reshoring.

Learn about our Supply Chain Management (SCM) Best Practice Frameworks here.

Readers of This Article Are Interested in These Resources

23-slide PowerPoint presentation

The Leadership at many Warehousing companies globally understands that they should spend less on Warehousing Operations, but is not aware of the real costs associated with it. In the same vein, most leaders are unable to tell how much is their human resources cost per facility.

Lack of

[read more]

27-slide PowerPoint presentation

As the last decisive step in customer service, a warehouse ensures cost effective distribution. Latest technological innovation has turned Warehousing into a Competitive Advantage. It offers untapped potential for improvement.

However, Warehousing is a hugely neglected part of global Supply

[read more]

113-slide PowerPoint presentation

This document provides a collection of 100+ Key Performance Indicators (KPIs) related to the Supply Chain functions listed further below.

Keeping in mind that each organization is different, the enclosed KPIs are intended as a general reference and their relevance depends on the specific

[read more]

4-page PDF document

These questions assess the ERP Consultant to gather Inventory & Warehouse Management requirements on customer organization. The applicant's answer will indicate their Inventory & Warehouse Management knowledge and information. This information is vital because ERP Consultants must be able to gather

[read more]

Shortage of labor, intensified demand from e-tailers (online retailers), and technological disruption is forcing organizations in the

Shortage of labor, intensified demand from e-tailers (online retailers), and technological disruption is forcing organizations in the