Editor's Note: Take a look at our featured best practice, 8D Problem Solving Process & Tools (206-slide PowerPoint presentation). The 8D Problem Solving Process has become a standard in many industries as problem solving or improvement process, as internal Corrective Action Request (CAR) Process or as Supplier Corrective Action Request (SCAR) Process.

The 8D Problem Solving Process Training Module includes:

1. [read more]

* * * *

“If I had an hour to save the world I would spend 59 minutes defining the problem and one minute finding solutions.” – Albert Einstein

“If I had an hour to save the world I would spend 59 minutes defining the problem and one minute finding solutions.” – Albert Einstein

The 8D (Eight Disciplines) Problem Solving Process is a team oriented and structured problem solving methodology that is mainly used to identify, correct and eliminate recurring problems.

The 8D Problem Solving Process focuses on the origin of the problem by determining root causes and establishes corrective and preventive actions.

The U.S. government first standardized the 8D Problem Solving Process during the Second World War, referring to it as Military Standard 1520. It was later popularized by the Ford Motor Company in the ‘60s and ‘70s.

Today, the 8D Problem Solving Process has become a standard in many industries as problem solving or improvement process, as internal Corrective Action Request (CAR) Process or as Supplier Corrective Action Request (SCAR) Process. The 8D Problem Solving Process can be an integral part of an Operational and Process Excellence initiative.

The benefits of a systematic Problem Solving Process are obvious.

- Create a shared understanding about how to systematically solve problems.

- Strengthen cross-functional teamwork, problem solving and collaboration capabilities.

- Reduce defects, lead times and costs through effective problem solving.

- Identify the underlying root cause(s) by applying effective problem solving tools.

- Develop effective process controls to prevent recurrence of known problems.

- Establish a systematic documentation of the Problem Solving Process.

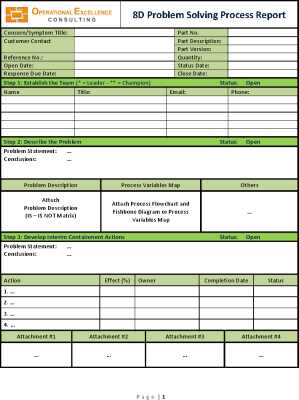

The 8D Problem Solving Process follows a systematic methodology using eight step or disciplines.

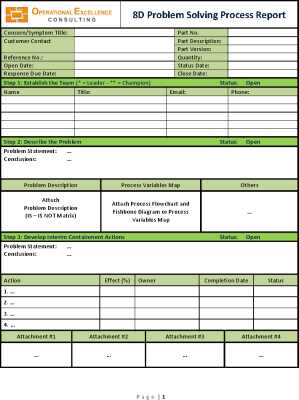

D1 Establish the Team: Establish a small group of people with the process and/or product knowledge, allocated time, authority, and skills in the required technical disciplines to solve the problem and implement corrective actions.

D2 Describe the Problem: Describe the internal or external problem by identifying “what is wrong with what” and detailing the problem in quantifiable terms. Develop a clear Problem Statement and Problem Description.

D3 Develop Interim Containment Actions: Define, verify and implement Interim Containment Action to isolate the effects of the problem from any internal and/or external Customer until Permanent Corrective (Preventive) Action are implemented.

D4 Define and Verify Root Cause(s) and Escape Point(s): Isolate and verify the root cause by testing each root cause theory against the Problem Description and test data. Isolate and verify the place in the process where the effect of the root cause could have been detected and contained but was not (escape point).

D5 Choose and Verify Permanent Corrective Actions: Select the best Permanent Corrective Actions to remove the root cause and to address the escape point in the process. Verify that both decisions will be successful when implemented and not cause any undesirable effects.

D6 Implement and Validate Permanent Corrective Actions: Plan and implement selected Permanent Corrective Actions, remove the Interim Containment Action. Monitor long-term results.

D7 Prevent Recurrence: Modify the necessary systems, including policies, methods, and procedures, to prevent recurrence of the problem and similar ones.

D8 Recognize Team and Individual Contribution: Complete the team experience and sincerely recognize both team and individual contributions. Celebrate success and identify lessons learned.

While some problem solving tools, such as the 5 Whys, Is – Is Not Matrix, Comparative Analysis and Root Cause Theory Testing are an integral part of the Global 8D Problem Solving Process, other tools need to be tailored to the organization’s requirements and can include Pareto Chart, Process Variables Map, Affinity Diagram, Interrelationship Diagram, Process Failure Mode and Effects Analysis, Histogram, Scatter Plot, Box Plot, Force Field Analysis, and Solution Selection Matrix.

Please review our presentation material Operational Excellence – 8D Problem Solving Process for more details about this very effective and efficient problem solving process.

256-slide PowerPoint presentation

[NOTE: Our 8D Problem Solving presentation has been trusted by an array of prestigious organizations, including industry leaders such as Apple, Cummins, Valeo, Saint-Gobain, Altec, Diebold, Destaco, Aptiv, SQM, Tutanota, Stratosphere Quality, Wakefield-Vette to name just a few.]

The 8D

[read more]

Do You Want to Implement Business Best Practices?

You can download in-depth presentations on 8D and 100s of management topics from the FlevyPro Library. FlevyPro is trusted and utilized by 1000s of management consultants and corporate executives.

For even more best practices available on Flevy, have a look at our top 100 lists:

These best practices are of the same as those leveraged by top-tier management consulting firms, like McKinsey, BCG, Bain, and Accenture. Improve the growth and efficiency of your organization by utilizing these best practice frameworks, templates, and tools. Most were developed by seasoned executives and consultants with over 20+ years of experience.

Readers of This Article Are Interested in These Resources

128-slide PowerPoint presentation

The 8D approach also emphasizes the importance of documentation and data analysis, ensuring that teams collect and analyze relevant information throughout the problem-solving process. This helps teams to make informed decisions and prioritize their actions based on the impact of the

[read more]

26-slide PowerPoint presentation

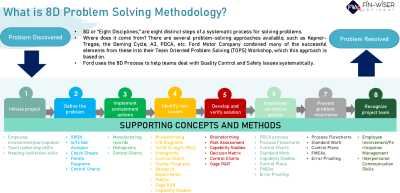

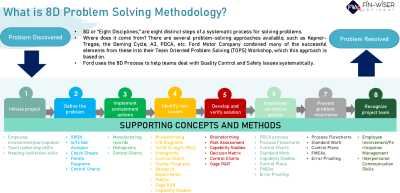

There are several problem-solving approaches available, such as Kepner-Tregoe, the Deming Cycle, A3, PDCA, etc. Ford Motor Company combined many of the successful elements from these into their Team Oriented Problem Solving (TOPS) Workshop, which this approach is based on. Corrective action

[read more]

3-page Word document

The 8 Disciplines of Problem Solving (8D) is a problem solving methodology designed to uncover the Root Cause of a problem, develop containment actions to protect customers, and then implement corrective action to prevent similar problems from occurring in the future. The 8D problem solving

[read more]

67-slide PowerPoint presentation

This PowerPoint template is designed to streamline the compilation of an 8D (Eight Disciplines) problem-solving report. The template covers the following report sections:

- D0: Plan

- D1: Initiate project team

- D2: Define the problem

- D3: Implement containment actions

- D4: Identify

[read more]

“If I had an hour to save the world I would spend 59 minutes defining the problem and one minute finding solutions.” – Albert Einstein

“If I had an hour to save the world I would spend 59 minutes defining the problem and one minute finding solutions.” – Albert Einstein