Artificial Intelligence (AI) has become a pivotal force in shaping product strategy across various industries. By leveraging AI, companies can gain a competitive edge through enhanced customer insights, improved product development processes, and personalized customer experiences. This transformative technology enables businesses to anticipate market trends, optimize operations, and deliver innovative solutions that meet evolving consumer demands.

Enhancing Customer Insights and Personalization

One of the most significant impacts of AI on product strategy is its ability to analyze vast amounts of data to generate deep customer insights. AI algorithms can sift through customer behavior data, social media interactions, and purchasing patterns to identify trends and preferences that are not immediately apparent. This level of analysis helps companies to tailor their products and services to meet the specific needs of their target audience. For instance, Netflix uses AI to analyze viewing patterns and recommend personalized content to its users, significantly enhancing user engagement and satisfaction. Similarly, Amazon leverages AI for its recommendation engines, resulting in increased sales through personalized shopping experiences.

Moreover, AI-driven analytics enable businesses to predict future consumer behavior with a higher degree of accuracy. By understanding customer preferences and market trends, companies can develop products that are more likely to succeed. This proactive approach to product development ensures that businesses stay ahead of the curve, capitalizing on emerging opportunities before their competitors do.

Additionally, AI facilitates the creation of dynamic pricing models that adapt to market demand, competitor pricing, and customer behavior in real-time. This capability allows companies to optimize their pricing strategy, maximizing profitability while ensuring customer satisfaction. For example, ride-sharing companies like Uber and Lyft use AI to implement surge pricing during periods of high demand, balancing supply and demand effectively.

Revolutionizing Product Development and Innovation

AI also plays a critical role in streamlining the product development process. Through the use of machine learning algorithms and predictive analytics, companies can identify potential design flaws, predict performance issues, and gather insights on how to improve their products. This leads to a more efficient development process, reducing time to market and increasing the likelihood of product success. For instance, automotive companies are using AI to simulate crash tests, speeding up the design process while ensuring safety standards are met.

Innovation is another area where AI significantly impacts product strategy. By analyzing emerging trends and patterns, AI can help identify new product opportunities and areas for innovation. For example, in the healthcare sector, AI is being used to develop personalized medicine, offering treatments that are tailored to an individual's genetic makeup. This not only improves patient outcomes but also opens up new market opportunities for pharmaceutical companies.

Furthermore, AI can enhance product features and functionality through intelligent automation and advanced data analysis. Smart home devices, such as thermostats and security cameras, use AI to learn from user behavior and automate settings for optimal performance and convenience. This application of AI not only improves the user experience but also differentiates products in a crowded market.

Optimizing Marketing and Sales Strategies

AI's impact extends beyond product development to include marketing and sales strategies. By analyzing customer data, AI can help identify the most effective marketing channels and messages for different segments of the market. This targeted approach to marketing ensures that companies can reach their audience more effectively, increasing conversion rates and enhancing ROI on marketing spend. For example, Coca-Cola has used AI to analyze social media data and identify emerging trends, enabling them to create targeted marketing campaigns that resonate with their audience.

Sales strategies also benefit from AI through the optimization of sales processes and the personalization of sales interactions. AI can predict which leads are most likely to convert and recommend the best approach to engage each prospect. Salesforce's AI platform, Einstein, provides sales teams with insights into customer needs and behavior, helping them to close deals more efficiently and effectively.

In conclusion, AI is reshaping product strategy by providing deep customer insights, streamlining product development, fostering innovation, and optimizing marketing and sales efforts. Companies that embrace AI in their strategic planning are better positioned to meet the demands of today's market, delivering products and services that are highly personalized, innovative, and successful. As AI technology continues to evolve, its role in shaping product strategy will only grow, offering endless possibilities for businesses willing to invest in this transformative technology.

Organizations today operate in an increasingly customer-centric environment where feedback and engagement are not just valuable, but pivotal to refining product strategy and ensuring competitive advantage. The dynamic nature of consumer preferences and the rapid pace of technological advancements necessitate a more integrated approach to leveraging customer insights. This strategy not only helps in enhancing product offerings but also in fostering stronger customer relationships and driving business growth.

Integrating Customer Feedback into Product Development

One of the most direct ways to leverage customer feedback is by integrating it into the product development lifecycle. This approach ensures that products are designed and iterated based on actual customer needs and preferences, leading to higher satisfaction and loyalty. According to a report by McKinsey, organizations that closely engage customers in the development process can increase their customer satisfaction scores by up to 20%. This process involves collecting feedback through various channels, analyzing the data to identify patterns and insights, and then applying these insights to make informed decisions about product features, design, and functionality.

For instance, digital platforms like user forums, social media, and direct surveys can be potent tools for gathering feedback. Advanced analytics and AI tools can then help in deciphering this vast amount of data to extract actionable insights. Adobe, for example, has successfully used customer feedback to evolve its Creative Cloud products, continuously adding features and improvements that address user requests and pain points.

Moreover, engaging customers in the development process through beta testing or co-creation workshops can provide valuable insights into user experience and product usability, enabling organizations to make adjustments before full-scale launch. This not only enhances the product but also makes customers feel valued and involved, increasing their commitment and loyalty to the brand.

Enhancing Customer Experience through Feedback Analysis

Customer feedback is a goldmine of insights into customer experience (CX) and satisfaction. By systematically analyzing feedback across touchpoints, organizations can identify areas of excellence and pinpoint issues or gaps in the customer journey. Gartner highlights that organizations that successfully analyze customer feedback to improve CX can increase their revenue by up to 15% while enhancing customer satisfaction. This analysis involves mapping the customer journey, identifying key touchpoints, and measuring satisfaction and feedback at each stage.

For example, using Net Promoter Score (NPS) surveys can help organizations gauge overall customer satisfaction and loyalty, while detailed feedback forms can provide insights into specific aspects of the product or service. Starbucks’ use of its My Starbucks Idea platform exemplifies how direct customer suggestions can lead to tangible product and service enhancements, from the introduction of new beverages to the implementation of digital payment options.

Furthermore, integrating feedback analysis with CRM systems can enable organizations to create more personalized customer experiences. By understanding individual customer preferences and issues, companies can tailor their communications, recommendations, and support, thereby enhancing satisfaction and loyalty.

Leveraging Feedback for Continuous Improvement and Innovation

Customer feedback is not just about addressing current issues or needs; it's also a critical driver for continuous improvement and innovation. By keeping a pulse on customer feedback, organizations can stay ahead of market trends, anticipate future needs, and innovate accordingly. Bain & Company's research underscores the importance of customer-centricity in innovation, noting that companies that excel in customer engagement are 4 times more likely to have higher financial performance.

This approach requires a culture that values feedback and sees it as an opportunity for growth rather than criticism. For instance, Amazon’s culture of customer obsession drives its innovation strategy, with new features and services often being direct responses to customer feedback. This has led to the development of groundbreaking products like Amazon Echo and services like Prime Now.

Moreover, leveraging customer feedback for innovation also involves identifying unmet needs or pain points that current products do not address. This can open up new opportunities for product development and market differentiation. Agile methodologies and rapid prototyping can help organizations quickly test and refine ideas based on customer feedback, reducing time to market and increasing the chances of success.

In conclusion, leveraging customer feedback and engagement to refine product strategy is a multifaceted approach that involves integrating feedback into product development, enhancing customer experience, and driving continuous improvement and innovation. By adopting a customer-centric mindset and utilizing advanced tools for feedback analysis, organizations can not only meet but exceed customer expectations, thereby driving loyalty, differentiation, and growth. Real-world examples from leading companies like Adobe, Starbucks, and Amazon illustrate the tangible benefits of this approach, highlighting its importance in today's competitive business landscape.

Understanding how to calculate product adoption rate is crucial for any organization looking to gauge the success of its products in the market. This metric not only provides insights into how well a product is being received by its target audience but also informs strategic decisions related to marketing, product development, and customer support. The calculation of product adoption rate involves analyzing sales data, customer feedback, and market trends to derive actionable insights that can drive growth and improve product offerings.

At its core, the product adoption rate measures the percentage of target customers who have adopted or started using a product within a specific timeframe. This calculation offers a clear view of a product's traction in the market and its potential for future growth. To accurately calculate this rate, organizations must first define what constitutes 'adoption' for their specific product—whether it's the completion of a purchase, subscription, or a different engagement metric. Once this baseline is established, the total number of new users over a given period can be divided by the total market opportunity or target customer base, then multiplied by 100 to get the adoption rate percentage.

However, calculating the product adoption rate is not just about crunching numbers. It requires a strategic approach to data analysis and interpretation. Organizations must consider various factors that can influence adoption rates, such as market saturation, competitive offerings, and changes in consumer behavior. Additionally, segmenting the adoption rate by demographics, regions, or customer segments can provide deeper insights into which areas are performing well and which need improvement. This level of analysis enables organizations to tailor their strategies to different segments, maximizing the potential for product success.

Framework for Calculating Product Adoption Rate

Developing a robust framework for calculating product adoption rate is essential for any organization looking to accurately measure and improve their product's market performance. The first step in this framework is to clearly define the target market and establish a baseline for what constitutes adoption. This might involve detailed market research and analysis to understand the size and characteristics of the potential customer base.

Next, organizations should gather and analyze relevant data over a specific period. This includes sales figures, customer usage data, and any other metrics that can indicate adoption levels. It's important to ensure that the data is accurate and comprehensive, covering all channels and touchpoints where customers might interact with the product. Consulting firms like McKinsey and Accenture often emphasize the importance of leveraging advanced analytics and customer relationship management (CRM) systems to track and analyze this data effectively.

Finally, the adoption rate should be calculated by dividing the number of new adopters by the total addressable market, then multiplying by 100 to get a percentage. This calculation can be further refined by segmenting the data to identify specific trends and patterns. For example, a higher adoption rate among younger demographics might influence an organization's marketing strategy, focusing more on digital channels and social media engagement.

Real-World Examples and Best Practices

Leading organizations across various industries have successfully leveraged product adoption rates to refine their strategies and achieve market success. For instance, technology companies often use adoption rates to assess the effectiveness of new software releases or updates. By closely monitoring these rates, they can quickly identify issues or barriers to adoption, such as user experience problems or lack of awareness, and address them through targeted interventions.

In the consumer goods sector, companies like Procter & Gamble analyze adoption rates to understand the impact of marketing campaigns and product innovations on consumer behavior. This data-driven approach allows them to allocate resources more effectively and adjust their strategies in real-time to maximize product adoption.

To ensure accurate and actionable insights, it's important to follow best practices when calculating and analyzing product adoption rates. This includes regularly updating data and metrics to reflect current market conditions, using a consistent methodology for comparison over time, and integrating qualitative feedback from customers to complement quantitative data. By adopting a comprehensive and strategic approach to calculating product adoption rate, organizations can enhance their decision-making processes and drive sustainable growth.

Conclusion

Calculating the product adoption rate is a critical process that requires a strategic framework, accurate data analysis, and a deep understanding of the market. By following the outlined steps and best practices, organizations can gain valuable insights into their product's performance and identify opportunities for improvement. Whether you're a startup looking to launch a new product or an established organization seeking to expand your market share, effectively calculating and leveraging the product adoption rate can be a key driver of success in today's competitive landscape.

Integrating sustainability into an organization's product strategy is no longer a choice but a necessity driven by increasing consumer demand and regulatory pressures. As the global focus on sustainability intensifies, organizations must adapt their strategies to not only remain competitive but also to contribute positively to the planet. This involves rethinking product life cycles, supply chains, and the very essence of product design.

Understanding Consumer Demand

Consumer awareness and demand for sustainable products have skyrocketed in recent years. A report by Nielsen showed that products with sustainability claims on-pack outperformed the growth rate of total products in their respective categories. Consumers are increasingly making purchasing decisions based on the environmental impact of their choices, pushing organizations to prioritize sustainability in their product strategy. To meet this demand, organizations must first conduct thorough market research to understand the specific sustainability concerns of their target market. This could range from reducing plastic use, ensuring fair labor practices, to sourcing materials sustainably.

Once these concerns are identified, organizations can then tailor their product development and marketing strategies to address them. For example, a clothing retailer could shift to using organic cotton or recycled materials and highlight these changes in their marketing campaigns. Additionally, organizations can leverage digital platforms to educate consumers on the sustainability efforts they are making, further aligning with consumer values and increasing brand loyalty.

It's also important for organizations to ensure that their sustainability claims are credible and verifiable. This can be achieved through certifications from recognized authorities or by providing transparency in their supply chain and production processes. This not only builds trust with consumers but also protects the organization from accusations of "greenwashing."

Adapting to Regulatory Demands

Regulatory demands for sustainability are increasing globally, with governments implementing policies that require organizations to adopt more sustainable practices. The European Union, for example, has been at the forefront of this movement with its Circular Economy Action Plan and the Green Deal. These regulations not only mandate higher levels of product recyclability and reduced resource consumption but also encourage innovation in sustainable product design.

To navigate these regulatory demands, organizations must stay abreast of changes in legislation and understand how they impact their products and supply chains. This requires a proactive approach to compliance, where sustainability is integrated into the Strategic Planning process. Organizations might need to invest in research and development to innovate new materials or processes that reduce environmental impact. For instance, a packaging company could develop biodegradable materials to replace plastic packaging, thus not only complying with regulatory demands but also gaining a competitive advantage in the market.

Collaboration with stakeholders, including suppliers, regulators, and industry groups, is also crucial in adapting to regulatory demands. By working together, organizations can share best practices, reduce costs, and influence the development of standards and regulations that support sustainable development.

Implementing Sustainability in Product Design and Development

At the core of integrating sustainability into product strategy is the redesign of products themselves. This involves adopting principles of sustainable design, such as minimizing waste, using renewable resources, and designing for product longevity and recyclability. For example, a consumer electronics manufacturer can design products that are easier to repair or upgrade, reducing electronic waste and extending the product's life cycle.

Implementing these changes requires a shift in the organization's culture and mindset, where sustainability becomes a key consideration in every decision-making process. This can be facilitated through training programs, setting sustainability performance metrics, and incorporating sustainability goals into the overall business strategy. Additionally, leveraging technologies such as digital modeling and simulation can help in designing more sustainable products by predicting their environmental impact during the design phase.

Real-world examples of organizations integrating sustainability into their product strategy include Patagonia, which uses recycled materials in its clothing lines, and Unilever, which has committed to making all of its plastic packaging reusable, recyclable, or compostable by 2025. These examples illustrate not only the feasibility of sustainable product strategies but also their potential to drive brand differentiation and competitive advantage.

In conclusion, integrating sustainability into an organization's product strategy requires a comprehensive approach that encompasses understanding consumer and regulatory demands, innovating in product design and development, and fostering a culture of sustainability. By taking these steps, organizations can not only meet the increasing demands for sustainability but also contribute positively to the global effort to achieve a more sustainable future.

In rapidly changing markets, organizations must adopt a dynamic approach to Risk Management within their Product Strategy. This involves continuously identifying, assessing, and mitigating risks that could impede the organization's ability to achieve its strategic goals. Given the pace at which market conditions, consumer preferences, and technology evolve, a proactive and flexible risk management strategy is essential for maintaining competitive advantage and ensuring long-term sustainability.

Understanding the Risk Landscape

The first step in integrating risk management into product strategy is to gain a comprehensive understanding of the risk landscape. This includes both internal and external risks. Internal risks might involve operational inefficiencies, technological obsolescence, or gaps in skills and capabilities. External risks, on the other hand, could include market volatility, regulatory changes, or geopolitical instability. A report by McKinsey emphasizes the importance of a holistic risk assessment approach that encompasses a wide range of potential risk factors. Organizations should employ both qualitative and quantitative methods to assess risks, leveraging data analytics and scenario planning to forecast potential impacts and outcomes.

It is also critical for organizations to maintain an agile risk assessment process that can adapt to new information and changing conditions. This means regularly updating risk assessments and being prepared to pivot strategies in response to emerging threats or opportunities. For example, the COVID-19 pandemic demonstrated how quickly external risks can arise and impact product strategies, underscoring the need for agility in risk management practices.

Moreover, engaging cross-functional teams in the risk assessment process can provide diverse perspectives and insights, enhancing the organization's ability to identify and address a broad spectrum of risks. This collaborative approach ensures that risk management is embedded throughout the organization, fostering a culture of risk awareness and proactive risk mitigation.

Strategic Risk Mitigation Techniques

Once risks have been identified and assessed, organizations must develop and implement strategies to mitigate these risks. This can involve a range of techniques, from diversifying product lines to mitigate market risks, to investing in new technologies to address technological obsolescence. For instance, a study by Boston Consulting Group (BCG) highlights the effectiveness of strategic partnerships and alliances as a risk mitigation strategy. By collaborating with other organizations, companies can share risks and leverage complementary strengths and capabilities.

Another key strategy is to build flexibility into the product development process. This can be achieved through modular product design, which allows for rapid adaptation to changing market demands or technological advancements. Additionally, adopting a lean approach to product development, characterized by rapid prototyping and iterative testing, can help organizations minimize the risks associated with product failure.

Financial risk management strategies, such as hedging against currency or commodity price fluctuations, can also play a crucial role in protecting the organization's bottom line. Furthermore, investing in risk management technologies, such as predictive analytics and risk management software, can enhance the organization's ability to anticipate and respond to risks in a timely and effective manner.

Building a Risk-Resilient Culture

Ultimately, the effectiveness of risk management within product strategy depends on the organization's culture. A risk-resilient culture is one that encourages openness, transparency, and continuous learning. Employees at all levels should feel empowered to identify and communicate potential risks without fear of retribution. Accenture's research underscores the importance of leadership in fostering a risk-resilient culture. Leaders should model risk-aware behaviors and promote an environment where risk management is viewed as a shared responsibility.

Training and education are also vital components of building a risk-resilient culture. Organizations should provide regular training on risk management principles and practices, as well as specific training related to the risks associated with their products and markets. This ensures that employees have the knowledge and skills needed to effectively manage risks.

In conclusion, integrating risk management into product strategy requires a comprehensive and proactive approach. By understanding the risk landscape, employing strategic risk mitigation techniques, and building a risk-resilient culture, organizations can navigate rapidly changing markets with confidence. While challenges will inevitably arise, a robust risk management framework can help organizations minimize negative impacts and seize opportunities for growth and innovation.

Emerging technologies such as Blockchain and the Internet of Things (IoT) are revolutionizing traditional industries by offering new opportunities for innovation, efficiency, and value creation. The impact of these technologies on product strategy is profound, requiring organizations to rethink their approach to development, delivery, and customer engagement. In this context, we will explore how Blockchain and IoT influence product strategy in traditional sectors, supported by actionable insights, real-world examples, and authoritative statistics.

Blockchain's Influence on Product Strategy

Blockchain technology, known for its key features of decentralization, transparency, and security, is significantly impacting product strategy in industries such as finance, supply chain management, and healthcare. Organizations are leveraging Blockchain to create products that offer enhanced security, traceability, and efficiency. For example, in the supply chain sector, Blockchain enables the development of solutions that provide real-time tracking of goods and transparent documentation of supply chain processes. This not only improves operational efficiency but also builds trust among stakeholders.

Moreover, Blockchain facilitates the creation of new business models. For instance, smart contracts automate transactions without the need for intermediaries, thereby reducing costs and increasing speed. A report by Deloitte highlighted that smart contracts could redefine traditional business processes by enabling more secure and efficient transaction methods. Organizations incorporating Blockchain into their product strategy can thus gain a competitive edge by offering innovative solutions that meet evolving customer expectations.

Additionally, Blockchain's ability to ensure data integrity and facilitate secure data sharing is transforming product strategies in the healthcare industry. By enabling secure and immutable patient records, Blockchain-based solutions can significantly improve patient care and data management practices. This technology thus not only influences the features and capabilities of products but also enhances the value proposition offered to customers.

IoT's Impact on Product Strategy

The Internet of Things (IoT) is another transformative technology reshaping product strategies across various industries. By enabling devices to collect and exchange data, IoT offers unprecedented opportunities for creating products that are intelligent, connected, and capable of delivering personalized experiences. In the manufacturing sector, IoT technologies are being used to develop smart machinery that can predict maintenance needs, thereby reducing downtime and operational costs. A study by Gartner predicted that by 2025, over 75% of organizations will have adopted IoT in some form, highlighting the technology's integral role in future product strategies.

IoT also plays a crucial role in enhancing customer engagement and satisfaction. Products equipped with IoT capabilities can provide organizations with valuable insights into user behavior and preferences, enabling the delivery of personalized services and experiences. For example, smart home devices use IoT technology to learn from user interactions, thereby automating and optimizing home environments according to individual preferences. This not only enhances the product's appeal but also strengthens customer loyalty.

Furthermore, IoT is driving sustainability in product strategy. Connected devices can monitor and manage energy consumption, waste production, and resource utilization more efficiently, supporting the development of eco-friendly products. Organizations incorporating IoT into their product strategies are therefore not only able to meet regulatory requirements but also cater to the growing consumer demand for sustainable products and practices.

Integrating Blockchain and IoT into Product Strategy

For organizations aiming to stay competitive in traditional industries, integrating Blockchain and IoT into product strategy is becoming increasingly important. This integration requires a comprehensive approach that includes Strategic Planning, Digital Transformation, and Innovation. Organizations must first identify the unique value proposition that these technologies can offer to their products and services. This involves analyzing market needs, customer expectations, and technological capabilities to identify opportunities for differentiation and value creation.

Implementing Blockchain and IoT technologies also demands a focus on Operational Excellence and Risk Management. Organizations must ensure that their infrastructure is capable of supporting these technologies and that they are compliant with relevant regulations and standards. This includes investing in cybersecurity measures to protect against potential threats and vulnerabilities associated with digital technologies.

Real-world examples of successful integration include the use of IoT in agriculture for precision farming products that optimize resource use and increase yields, and Blockchain in the financial sector for secure and efficient payment solutions. These examples demonstrate how traditional industries can leverage emerging technologies to develop innovative products that meet the evolving needs of the market.

In conclusion, the impact of Blockchain and IoT on product strategy in traditional industries is profound and multifaceted. By offering new opportunities for innovation, efficiency, and customer engagement, these technologies are enabling organizations to redefine their product strategies. To capitalize on these opportunities, organizations must adopt a strategic approach that includes a thorough understanding of the technologies, a focus on operational excellence, and a commitment to continuous innovation.

Integrating Virtual Reality (VR) and Augmented Reality (AR) technologies into product strategy offers transformative opportunities for the retail and education sectors. These technologies not only enhance customer and student experiences but also provide organizations with innovative tools for marketing, training, and product development. By understanding and leveraging VR and AR, organizations can create immersive experiences that elevate their brand, improve learning outcomes, and drive sales.

Influence on Retail Sector Product Strategy

For the retail sector, VR and AR technologies have revolutionized the way customers interact with products. VR allows customers to immerse themselves in virtual environments, experiencing products in a way that was previously impossible without physical presence. AR, on the other hand, overlays digital information onto the real world, enabling customers to visualize products in their own space. This has significant implications for product strategy, particularly in enhancing customer engagement, personalization, and reducing the gap between online and offline shopping experiences.

One actionable insight for retail organizations is to integrate AR into their mobile applications to enable customers to "try before they buy." For example, furniture retailers can use AR to allow customers to visualize how a piece of furniture would look in their home. This not only enhances the shopping experience but also reduces the likelihood of returns, a significant cost for online retailers. Similarly, VR can be used for virtual showrooms, allowing customers to explore a wide range of products without the need for physical inventory. This can be particularly beneficial for organizations looking to expand their market reach without the significant investment in physical retail spaces.

Real-world examples of successful integration of VR and AR in retail include IKEA's AR app, IKEA Place, which lets customers visualize how furniture fits in their space, and Sephora's Virtual Artist app, which uses AR for customers to try on makeup. These initiatives have not only enhanced customer experience but also driven sales by reducing the uncertainty associated with online shopping. According to a report by Accenture, incorporating immersive experiences in retail can increase conversion rates by up to 40%.

Influence on Education Sector Product Strategy

In the education sector, VR and AR technologies have the potential to transform traditional learning models by making educational content more interactive, engaging, and accessible. VR can transport students to different times and places, offering experiential learning opportunities that are otherwise not possible. AR can enhance textbooks and classroom materials with interactive, 3D content, making learning more engaging and effective. This shift towards immersive learning experiences requires organizations to rethink their product strategy, focusing on developing content and platforms that leverage these technologies to improve learning outcomes.

An actionable insight for educational organizations is to develop or partner with platforms that offer VR and AR-enhanced curriculums. For instance, creating AR applications that bring historical events to life or VR simulations that allow students to conduct virtual science experiments can significantly enhance the learning experience. Moreover, these technologies can provide personalized learning experiences, adapting to each student's pace and style of learning, which is a key factor in improving educational outcomes.

Real-world examples include Google Expeditions, which offers VR field trips to places like Mars and the Great Barrier Reef, and the AR app Anatomy 4D, which transforms the way students learn about the human body. These examples underscore the potential of VR and AR to make learning more engaging and effective. According to Gartner, by 2023, more than 60% of the education sector will be using VR and AR technologies for learning purposes.

In conclusion, the integration of VR and AR technologies into product strategy presents significant opportunities for the retail and education sectors. For retail, it offers innovative ways to enhance customer engagement and bridge the gap between online and offline experiences. In education, it transforms learning models by making educational content more interactive and personalized. Organizations that successfully leverage these technologies can not only improve customer and student experiences but also gain a competitive edge in their respective sectors.

A strong product vision statement is a foundational element in guiding an organization's long-term product strategy and innovation. It serves as a north star, providing direction and purpose to the product development teams, and aligning all stakeholders towards a common goal. In the rapidly evolving market landscapes, where customer preferences and technological advancements can shift dramatically, a well-articulated product vision is crucial for maintaining strategic focus and fostering innovation.

The Importance of a Product Vision Statement

A product vision statement encapsulates the essence of the product's purpose, its core promise to customers, and its strategic direction. It is not just a declaration of intent but a roadmap that guides the product development process. A compelling vision statement helps in making strategic decisions that align with the long-term goals of the organization. According to McKinsey, organizations with a clear, well-defined product vision are 50% more likely to report market share gains and twice as likely to report profit margins above their industry average.

Moreover, a strong product vision fosters a culture of innovation within the organization. It encourages teams to explore new ideas and technologies that align with the vision, thereby driving product innovation. It also helps in prioritizing product features, making trade-offs, and allocating resources efficiently. In essence, the product vision acts as a guiding light, ensuring that every product decision supports the organization's overarching goals.

Additionally, a clear product vision enhances stakeholder alignment and engagement. It ensures that everyone, from the executive team to the product developers, understands the strategic importance of the product and its potential impact on the market. This shared understanding fosters a sense of purpose and commitment, which is critical for navigating the challenges of product development and market introduction.

Guiding Long-Term Product Strategy

Developing a long-term product strategy requires a deep understanding of the market, customer needs, and competitive landscape. A strong product vision statement provides a framework for this analysis, helping organizations identify opportunities for differentiation and competitive advantage. For example, Apple's vision of creating "intuitive, powerful, and accessible products" has guided its strategy of continuous innovation and design excellence, enabling it to dominate the consumer electronics market.

A product vision also plays a crucial role in strategic planning, helping organizations set realistic goals and objectives. By defining what the organization aims to achieve with the product in the long term, the vision statement serves as a basis for developing a roadmap of initiatives and milestones. This roadmap not only outlines the path to achieving the product vision but also helps in monitoring progress and making necessary adjustments to the strategy.

Furthermore, in the context of digital transformation and technological disruption, a product vision can help organizations navigate uncertainty. It provides a strategic anchor, enabling organizations to adapt their product strategy in response to emerging trends and technologies without losing sight of their long-term goals. This adaptability is essential for sustaining competitive advantage in dynamic markets.

Fostering Innovation

Innovation is at the heart of long-term product success. A compelling product vision inspires and motivates teams to push the boundaries of what is possible, driving innovation in product features, design, and user experience. For instance, Google's vision to "organize the world's information and make it universally accessible and useful" has spurred innovations such as Google Search, Maps, and Assistant, which have revolutionized how people access and use information.

A product vision also provides a criterion for evaluating new ideas and innovations. It helps organizations distinguish between opportunities that are aligned with their vision and those that are not, ensuring that innovation efforts are focused and strategic. This strategic focus is crucial for maximizing the return on investment in research and development and for achieving a sustainable competitive edge.

Moreover, a strong product vision facilitates collaboration and cross-functional synergy, which are essential for innovation. It brings together diverse perspectives and expertise, fostering an environment where innovation can thrive. By aligning the efforts of different teams towards a common vision, organizations can accelerate the development of innovative products and solutions that meet the evolving needs of their customers.

In conclusion, a strong product vision statement is indispensable for guiding long-term product strategy and fostering innovation. It provides direction, enhances strategic decision-making, and aligns stakeholders, thereby enabling organizations to navigate market complexities and sustain competitive advantage. As the business landscape continues to evolve, the role of a clear and compelling product vision in driving product success and organizational growth cannot be overstated.

Incorporating Artificial Intelligence (AI) into the strategic framework of a Software as a Service (SaaS) organization is not just an innovative approach to staying competitive; it is becoming a necessity. AI technologies offer unparalleled opportunities for SaaS organizations to enhance product strategy and customer experience. By leveraging AI, organizations can achieve higher efficiency, personalized customer experiences, and innovative product features that can significantly differentiate their offerings in a crowded market.

Enhancing Product Strategy with AI

AI can profoundly impact the product strategy of SaaS organizations by enabling the development of smarter, more adaptive solutions. First, AI-driven analytics can provide deeper insights into customer behavior and preferences, allowing organizations to tailor their product development efforts more closely to market demands. For instance, predictive analytics can forecast future trends and user needs, enabling organizations to prioritize features or services that will deliver the most value. Furthermore, AI can automate routine tasks, freeing up human resources to focus on more strategic activities such as innovation and customer engagement. This shift not only improves operational efficiency but also accelerates the pace of product development and enhancement.

Moreover, incorporating AI into products can enhance their value proposition. Features such as personalized recommendations, automated customer service chatbots, and intelligent analytics tools can significantly improve the user experience, making products more attractive to potential customers. For example, Salesforce, a leading CRM SaaS provider, uses AI in its Einstein platform to offer predictive sales insights, automated customer service, and personalized marketing, thereby enhancing its overall product offering.

Finally, AI can aid in the strategic decision-making process by providing organizations with actionable insights derived from large datasets. This capability enables more informed decisions regarding product development, market positioning, and customer engagement strategies. AI’s ability to analyze and interpret complex data patterns can uncover opportunities for innovation that might otherwise go unnoticed, thereby supporting a more dynamic and responsive product strategy.

Improving Customer Experience through AI

AI technologies have the power to transform the customer experience, making it more personalized, efficient, and engaging. By analyzing customer data, AI can help organizations understand individual customer needs and preferences, enabling the delivery of customized content, recommendations, and services. This level of personalization not only enhances customer satisfaction but also fosters loyalty and retention. For instance, Netflix uses AI algorithms to personalize viewing recommendations for its users, significantly enhancing user engagement and satisfaction.

Additionally, AI-powered chatbots and virtual assistants can provide 24/7 customer support, answering queries, solving problems, and even guiding users through complex processes. This not only improves the customer experience by offering immediate assistance but also reduces the workload on human customer service representatives, allowing them to focus on more complex issues. According to Gartner, AI-driven customer service technologies are expected to handle over 85% of customer interactions by 2025, highlighting the growing importance of AI in customer experience strategies.

Moreover, AI can play a crucial role in identifying and predicting customer churn, enabling organizations to take proactive measures to retain at-risk customers. By analyzing customer interaction data, AI can identify patterns and signals that indicate a customer is likely to churn, such as decreased usage or negative feedback. This allows organizations to intervene early, perhaps by offering personalized incentives or addressing specific concerns, thereby improving customer retention rates.

Implementing AI in SaaS Organizations

Implementing AI within a SaaS organization requires a strategic approach. It begins with identifying key areas where AI can have the most significant impact, such as customer service, product personalization, or operational efficiency. Once these areas are identified, organizations should invest in the necessary AI technologies and talent to develop and integrate AI capabilities into their products and processes. This might involve hiring AI specialists or partnering with AI technology providers.

Furthermore, organizations must ensure that their data infrastructure is robust and capable of supporting AI initiatives. This includes implementing data management practices that ensure data quality, security, and accessibility. Additionally, fostering a culture of innovation and continuous learning is crucial for organizations to adapt to the rapidly evolving AI landscape. Encouraging collaboration between AI experts and other departments can facilitate the integration of AI into various aspects of the organization, from product development to customer service.

Lastly, it's essential for organizations to remain compliant with data protection regulations and ethical guidelines when implementing AI. This involves being transparent with customers about how their data is being used and ensuring that AI technologies are deployed in a manner that is fair and non-discriminatory.

In conclusion, incorporating AI into the strategic framework of a SaaS organization offers significant opportunities to enhance product strategy and customer experience. By leveraging AI for deeper insights, personalized experiences, and operational efficiency, organizations can not only stay competitive but also set new standards for innovation and customer satisfaction in the SaaS industry.

In a saturated market, organizations face the challenge of standing out among a plethora of competitors, all vying for the same customer base. The key to success lies in effectively managing and prioritizing the product portfolio to ensure that resources are allocated to the most promising opportunities. This requires a strategic approach, leveraging insights from market research, consumer behavior analysis, and competitive intelligence.

Strategic Portfolio Analysis

Strategic Portfolio Analysis is a critical tool for organizations aiming to optimize their product offerings in a saturated market. This involves evaluating each product's market performance and potential based on factors such as market growth, market share, profitability, and alignment with the organization's core competencies and strategic objectives. A popular framework for this analysis is the Boston Consulting Group (BCG) Matrix, which categorizes products into four quadrants—Stars, Cash Cows, Question Marks, and Dogs—based on their market growth rate and relative market share. Products categorized as Dogs may be phased out, while Stars and Cash Cows are prioritized for investment.

For example, Apple Inc. regularly conducts portfolio analysis to decide which products to invest in, develop, or discontinue. This strategic approach has enabled Apple to maintain its market leadership and innovate within its product lines effectively. By focusing on high-growth areas like wearable technology and services, Apple continues to thrive in a highly competitive technology market.

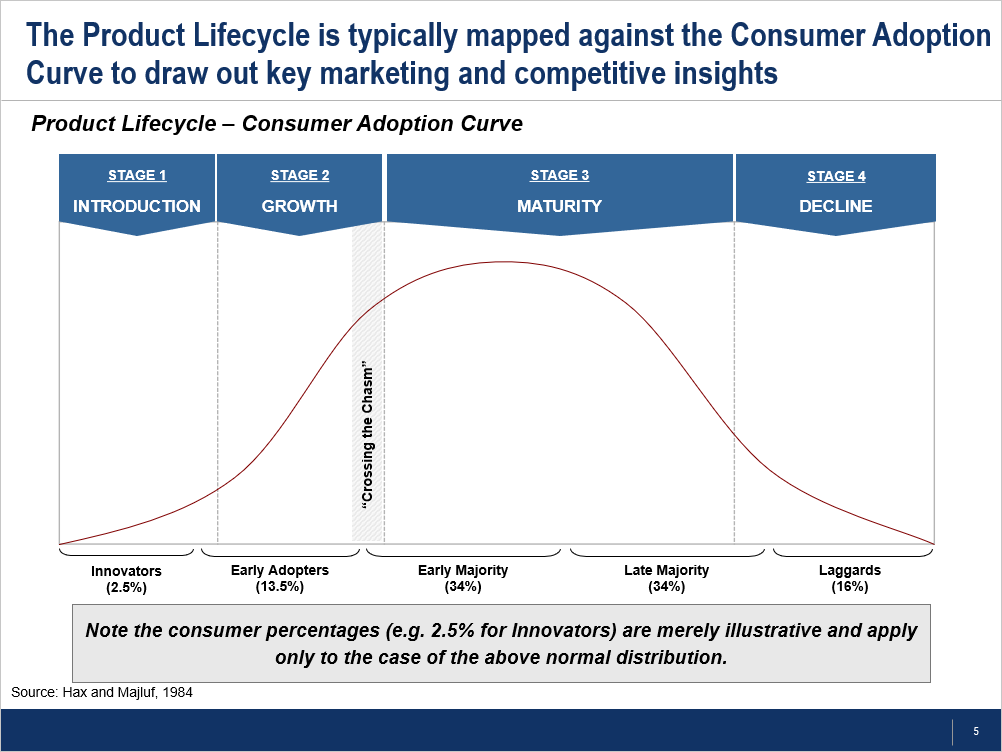

Organizations should also consider the Product Life Cycle stage of each offering. Products in the growth or maturity stage may warrant further investment, while those in decline may need to be divested. This dynamic approach to portfolio management ensures that the organization's product mix remains relevant and competitive.

Customer-Centric Innovation

Innovation is paramount in a saturated market. However, it must be strategically aligned with customer needs and preferences to be effective. Organizations should adopt a customer-centric approach to innovation, focusing on solving real problems and enhancing customer experience. This involves leveraging customer data and insights to identify unmet needs and emerging trends. According to McKinsey, organizations that excel in customer-centric innovation are 60% more profitable compared to their peers.

Procter & Gamble (P&G) exemplifies customer-centric innovation through its "Connect + Develop" program, which collaborates with external partners to co-create products that meet evolving consumer needs. This strategy has led to the development of blockbuster products like the Swiffer and Febreze, which were developed in response to specific consumer pain points identified through extensive market research.

Furthermore, embracing Digital Transformation in the innovation process can enhance agility and responsiveness to market changes. Digital tools and platforms can facilitate rapid prototyping, customer feedback loops, and data-driven decision-making, enabling organizations to iterate and refine products more efficiently.

Market Segmentation and Positioning

Effective market segmentation and positioning are crucial for organizations to differentiate their offerings in a saturated market. This involves identifying distinct customer segments based on demographic, psychographic, behavioral, and geographic criteria and tailoring product offerings and marketing strategies to meet the unique needs of each segment. A well-defined market segmentation strategy allows organizations to focus their resources on the most lucrative segments and achieve a competitive advantage.

Nike's segmentation strategy serves as a powerful example. By identifying and targeting specific customer segments such as professional athletes, sports enthusiasts, and fashion-conscious consumers, Nike has developed tailored products and marketing campaigns that resonate strongly with each group. This focused approach has helped Nike to maintain its dominance in the highly competitive athletic apparel and footwear market.

Positioning involves crafting a unique value proposition that distinguishes the organization's offerings from competitors. This requires a deep understanding of the competitive landscape and the ability to communicate the unique benefits and features of the product in a way that resonates with the target market. Effective positioning helps to build brand equity and loyalty, which are invaluable assets in a saturated market.

Managing and prioritizing a product portfolio in a saturated market demands a strategic, customer-focused approach. By conducting thorough Strategic Portfolio Analysis, fostering Customer-Centric Innovation, and employing targeted Market Segmentation and Positioning strategies, organizations can navigate competitive pressures and achieve sustainable growth.

Advanced Product Quality Planning (APQP) is a structured process aimed at ensuring customer satisfaction with new products or processes. This methodology is highly regarded in the automotive industry, where the complexity and safety requirements of products make quality planning especially critical. APQP influences product strategy in the automotive industry by aligning product development processes with customer expectations, regulatory requirements, and company goals. This alignment is achieved through comprehensive planning and evaluation at each stage of product development, from concept through to production and post-launch support.

Strategic Alignment and Risk Management

APQP serves as a strategic tool that aligns product development with organizational goals and customer expectations. It emphasizes the importance of understanding customer needs and translating them into specific design and performance criteria. This customer-centric approach ensures that new automotive products meet or exceed market expectations, thereby enhancing customer satisfaction and loyalty. Moreover, APQP integrates Risk Management into the product development process, identifying potential failures and their causes early in the product lifecycle. By doing so, organizations can proactively address risks, leading to reduced warranty costs, fewer recalls, and improved brand reputation.

For instance, a leading automotive manufacturer might employ APQP to streamline the introduction of a new vehicle model. Through early identification of potential safety issues and performance bottlenecks, the organization can implement corrective measures before these problems escalate into costly recalls or damage to the company's reputation. This proactive approach not only safeguards the end-users but also protects the organization from financial losses and regulatory penalties.

Additionally, APQP facilitates cross-functional team collaboration, bringing together expertise from design, engineering, quality, and manufacturing departments. This collaborative effort ensures that all aspects of product quality and safety are considered from the outset, leading to more innovative and competitive products. By fostering a culture of quality and continuous improvement, organizations can better respond to market changes and technological advancements, maintaining a competitive edge in the automotive industry.

Cost Reduction and Efficiency Improvement

Implementing APQP can lead to significant cost savings and efficiency improvements. By identifying and resolving quality issues during the early phases of product development, organizations can avoid the high costs associated with late-stage changes. Early problem detection is much less expensive than rectifying issues after production has commenced or, worse, after the product has been released to the market. The APQP framework promotes a "do it right the first time" philosophy, which minimizes waste and reduces the need for rework, leading to more efficient production processes and shorter time-to-market.

For example, an automotive organization might use APQP to optimize the design of a new engine component. Through detailed Failure Mode and Effects Analysis (FMEA), the team identifies a potential flaw that could lead to premature wear. Addressing this issue during the design phase is significantly cheaper and faster than modifying the component during production or, worse, conducting a post-sale recall campaign. Consequently, the organization not only saves on production costs but also enhances the component's reliability and longevity, contributing to customer satisfaction and loyalty.

Moreover, APQP supports the effective management of suppliers and external partners. By involving key suppliers in the APQP process, organizations can ensure that all components and materials meet the required quality standards. This collaborative approach leads to a more integrated supply chain, where quality issues are addressed collaboratively and efficiently, further reducing costs and lead times.

Compliance and Competitive Advantage

In the highly regulated automotive industry, compliance with international quality standards and safety regulations is non-negotiable. APQP facilitates compliance by incorporating regulatory requirements into each stage of the product development process. This systematic approach ensures that products not only meet customer expectations but also comply with legal and industry standards, avoiding costly penalties and recalls. Furthermore, adherence to APQP processes can enhance an organization's reputation for quality and reliability, providing a competitive advantage in the global market.

Consider the case of an automotive organization that leverages APQP to exceed the minimum safety standards set by regulatory bodies. By doing so, the organization not only ensures compliance but also positions its products as superior in terms of safety and quality. This differentiation strategy can be particularly effective in markets where consumers are highly safety-conscious, leading to increased market share and profitability.

In conclusion, APQP plays a pivotal role in shaping product strategy in the automotive industry. By ensuring strategic alignment, enhancing efficiency, reducing costs, and ensuring compliance, APQP enables organizations to deliver high-quality products that meet customer and regulatory requirements. Through its structured and proactive approach to quality planning, APQP provides a framework for continuous improvement and innovation, driving competitive advantage and long-term success in the automotive sector.

Predictive analytics is a game-changer for organizations aiming to innovate and ensure their products meet market demands efficiently. By leveraging historical data, statistical algorithms, and machine learning techniques, organizations can predict future trends, customer behaviors, and potential market changes. This forward-looking approach is particularly valuable in product development and achieving market fit in a rapidly evolving consumer landscape.

Understanding Customer Needs through Predictive Analytics

Predictive analytics allows organizations to delve deep into customer data and identify emerging trends before they become mainstream. By analyzing patterns in customer behavior, purchase history, and social media engagement, organizations can predict future buying behaviors and preferences. This insight is invaluable for product development teams, enabling them to design products that not only meet current customer needs but also anticipate future desires. For instance, a report by McKinsey highlights how consumer-goods companies using advanced analytics were able to achieve a 5% increase in revenue by aligning their product features with customer preferences more accurately.

Moreover, predictive analytics can segment customers more effectively, identifying niche markets that may have been overlooked. This enables organizations to tailor their product development efforts to cater to specific segments, increasing the likelihood of market fit. For example, Netflix uses predictive analytics to not just recommend movies to its users but also to decide which shows to produce, ensuring a strong product-market fit from the outset.

Additionally, predictive analytics can enhance customer feedback loops. By predicting which customers are likely to provide valuable feedback, organizations can proactively engage with them, gathering insights that can inform product development and refinement. This proactive approach ensures that products evolve in line with changing customer expectations, maintaining relevance and appeal in a dynamic market.

Optimizing Product Launches and Marketing Strategies

Predictive analytics plays a crucial role in optimizing product launches and marketing strategies. By predicting market trends and consumer behaviors, organizations can identify the most opportune moments to launch new products. This timing is critical to ensuring a product gains traction and achieves a strong market fit before competitors. A study by Accenture revealed that predictive analytics could increase the success rate of new product launches by up to 50% by ensuring that timing, messaging, and targeting align with market dynamics.

Furthermore, predictive analytics can inform marketing strategies, enabling organizations to create personalized and targeted campaigns. By understanding future customer behaviors, organizations can design marketing messages that resonate deeply with their target audience, increasing engagement and conversion rates. For example, Amazon's recommendation engine, powered by predictive analytics, significantly enhances customer experience by personalizing product recommendations, thereby increasing sales.

Predictive analytics also allows organizations to optimize pricing strategies. By predicting how price changes can affect demand for a product, organizations can adjust their pricing models in real-time, maximizing profitability while ensuring market competitiveness. Dynamic pricing strategies, informed by predictive analytics, have been successfully implemented by airlines and e-commerce platforms to adjust prices based on demand predictions, leading to increased revenue and market share.

Enhancing Operational Efficiency and Risk Management

Predictive analytics not only aids in product development and market fit but also enhances operational efficiency and risk management. By predicting potential supply chain disruptions, organizations can proactively adjust their operations to mitigate risks. For instance, predictive analytics can forecast demand spikes or supply shortages, allowing organizations to adjust their inventory levels accordingly, reducing the risk of stockouts or excess inventory.

Moreover, predictive analytics can identify potential quality issues before they affect a large batch of products. By analyzing production data, organizations can pinpoint anomalies that may indicate a quality issue, enabling them to address the problem early in the production process. This proactive approach not only saves costs associated with recalls and reputational damage but also ensures that the product development process is more streamlined and efficient.

In conclusion, predictive analytics offers organizations a powerful tool to navigate the complexities of modern markets. By providing deep insights into customer behaviors, market trends, and operational risks, predictive analytics enables organizations to develop products that meet and exceed market expectations, optimize product launches, and enhance operational efficiency. As the consumer landscape continues to evolve, the organizations that effectively leverage predictive analytics will be best positioned to thrive.

Customer feedback is a critical component in the iterative process of refining product strategy. It provides organizations with direct insights into what their customers value, their pain points, and how a product or service could better meet their needs. This feedback loop enables organizations to make informed decisions that align product development with customer expectations, thereby enhancing customer satisfaction, loyalty, and ultimately, business success.

The Importance of Customer Feedback in Strategic Planning

Strategic Planning involves setting out a vision for the future and mapping out the steps required to get there. Customer feedback plays a pivotal role in this process by ensuring that the strategies developed are grounded in real customer needs and experiences. It allows organizations to pivot and adapt their strategies based on actionable insights. For instance, a study by McKinsey highlighted that customer-centric organizations are 60% more profitable compared to companies that don't focus on customers. This underscores the importance of integrating customer feedback into the Strategic Planning process to ensure that product offerings remain relevant and competitive.

Moreover, customer feedback provides valuable data that can help in identifying emerging trends and customer preferences. This information is crucial for Risk Management and Performance Management, as it helps organizations to anticipate market changes and adapt their strategies accordingly. By regularly collecting and analyzing customer feedback, organizations can maintain a clear understanding of the evolving market landscape and adjust their product strategy to stay ahead of competitors.

Furthermore, customer feedback is essential for Innovation. It encourages organizations to think outside the box and explore new ways to meet customer needs. For example, feedback might reveal a gap in the market that the organization can fill with a new product or service. This iterative process of feedback, analysis, and adaptation is key to sustaining long-term growth and relevance in a rapidly changing market.

Refining Product Strategy Through Customer Feedback

Refining product strategy over time is not a one-off task but a continuous process of improvement. Customer feedback is instrumental in this process. It helps organizations to understand how their products are being used in the real world, what features are most valued by customers, and what aspects could be improved. For instance, a report by Accenture showed that 91% of consumers are more likely to shop with brands that recognize, remember, and provide relevant offers and recommendations. This statistic highlights the importance of using customer feedback to tailor product offerings and improve customer engagement.

Implementing a structured process for collecting, analyzing, and acting on customer feedback is crucial. This might involve surveys, customer interviews, focus groups, or analysis of customer behavior data. The key is to ensure that feedback is systematically integrated into the decision-making process. This can help organizations to prioritize product features, identify areas for improvement, and develop a roadmap for future development that is closely aligned with customer needs.

Additionally, customer feedback can also provide insights into the effectiveness of marketing strategies and customer service processes. It can highlight areas where customers feel their needs are not being met or where their expectations are not aligned with the organization's messaging. This feedback is invaluable for refining not just the product strategy but also marketing and customer service strategies to ensure a consistent and customer-centric approach across all touchpoints.

Real World Examples of Customer Feedback Shaping Product Strategy

Many leading organizations have successfully leveraged customer feedback to refine their product strategies. For example, Apple is known for its customer-centric approach to product development. The company's decision to remove the headphone jack from the iPhone was based on extensive customer feedback that prioritized device slimness and battery life over the traditional headphone connection. This move, while controversial, was informed by a deep understanding of customer preferences and ultimately contributed to the product's success.

Another example is Netflix, which uses sophisticated algorithms to analyze customer viewing patterns and feedback. This data-driven approach allows Netflix to make informed decisions about which shows to produce or acquire, ensuring that their content catalog remains closely aligned with viewer preferences. The success of this strategy is evident in the company's strong subscriber growth and high levels of customer satisfaction.

In conclusion, customer feedback is an invaluable resource for organizations looking to refine their product strategy over time. It provides a direct line of insight into customer needs and preferences, enabling organizations to make informed decisions that enhance customer satisfaction and drive business success. By integrating customer feedback into Strategic Planning, Risk Management, and Innovation processes, organizations can ensure that their product offerings remain relevant, competitive, and aligned with customer expectations.

Advanced Product Quality Planning (APQP) is a structured process aimed at ensuring customer satisfaction through the early identification and prevention of potential failure points in product development and manufacturing processes. Integrating APQP into product strategy can significantly enhance quality and customer satisfaction across industries. This integration requires a strategic approach to planning, development, and execution, ensuring that quality is built into products from the outset rather than inspected in at the end.

Strategic Planning and APQP Integration

The first step in integrating APQP into product strategy involves incorporating quality planning into the strategic planning phase. This means that from the very inception of a product idea, quality considerations are paramount. Organizations should establish cross-functional teams that include members from product development, quality, manufacturing, and even marketing to ensure a comprehensive approach to quality planning. This team is responsible for defining the quality standards and performance indicators that the product must meet, aligned with customer expectations and market demands.

Effective integration of APQP into strategic planning also requires a robust risk management framework. By identifying potential quality and production risks at the earliest stages, organizations can develop mitigation strategies that are both cost-effective and efficient. This proactive approach to risk management not only enhances product quality but also significantly reduces the time and resources spent on rework and corrections during later stages of product development and manufacturing.

Moreover, strategic planning should involve setting clear objectives for APQP implementation, including timelines, milestones, and accountability measures. This ensures that quality planning is not just a theoretical exercise but a practical, integral part of the product development lifecycle. Organizations that successfully integrate APQP into their strategic planning benefit from a more streamlined development process, reduced time to market, and products that meet or exceed customer quality expectations.

Development and Execution of APQP

Once strategic planning has incorporated APQP principles, the focus shifts to the development and execution stages. Here, the detailed planning of APQP comes to life through the application of its five phases: Plan and Define Program, Product Design and Development, Process Design and Development, Product and Process Validation, and Feedback, Assessment, and Corrective Action. Each phase is critical to ensuring that quality is not compromised at any stage of product development.

During the Product Design and Development phase, for instance, Design Failure Mode and Effects Analysis (DFMEA) is used to systematically evaluate and mitigate risks associated with product design. Similarly, Process Failure Mode and Effects Analysis (PFMEA) during the Process Design and Development phase helps in identifying and addressing potential process-related failures. These tools, integral to the APQP process, facilitate a deep understanding of potential failure points and the development of strategies to prevent them, thereby enhancing product reliability and customer satisfaction.

Execution of APQP also demands a strong focus on data and metrics. Organizations must establish key performance indicators (KPIs) related to product quality and customer satisfaction, and rigorously monitor these through the development and production cycles. This data-driven approach enables continuous improvement, allowing organizations to refine processes, reduce defects, and improve overall product quality. The emphasis on feedback and corrective action in the final phase of APQP ensures that lessons learned are systematically applied to future projects, fostering a culture of continuous quality improvement.

Industry-Specific Applications and Benefits

While APQP originated in the automotive industry, its principles are universally applicable across sectors. In the healthcare industry, for example, integrating APQP into product strategy can significantly enhance the quality and safety of medical devices. Rigorous quality planning and risk management are essential in an industry where product failures can have dire consequences for patient health. Similarly, in the aerospace sector, the emphasis on design and process validation can help in meeting the stringent quality and safety standards required by regulatory authorities.

In consumer electronics, where market cycles are short and consumer expectations for quality and innovation are high, APQP can help organizations streamline their product development processes, reduce time to market, and ensure that new products meet quality standards. This not only enhances customer satisfaction but also strengthens brand reputation and competitiveness in a fast-paced market.

Moreover, the integration of APQP into product strategy can drive significant financial benefits. By reducing the incidence of defects and rework, organizations can lower their production costs and improve profit margins. Additionally, products that consistently meet or exceed quality expectations tend to have higher customer loyalty and lower warranty and service costs, contributing to long-term financial performance.

Integrating APQP into product strategy offers a systematic approach to quality planning that can significantly improve product quality and customer satisfaction across industries. By embedding quality considerations into strategic planning, rigorously applying APQP principles during product development and execution, and adapting these practices to the specific needs of different industries, organizations can achieve operational excellence and competitive advantage. This strategic focus on quality not only meets the current demands of customers but also positions organizations to respond more effectively to future market changes and challenges.

Transitioning from prototype to production is a critical phase in the lifecycle of a product. It involves scaling the development process from an initial, often hand-crafted, model to a fully developed item ready for the market. This stage is fraught with challenges, including cost overruns, delays, and quality control issues. However, with a strategic approach, organizations can navigate this transition efficiently. Understanding how to go from prototype to production is essential for maintaining momentum and ensuring the viability of the product in a competitive market.

The first step in this process is to conduct a thorough review of the prototype's performance, gathering feedback from all stakeholders involved. This includes assessing the design, functionality, and user experience against the initial objectives. It's crucial to identify any discrepancies early on and adjust the design before moving forward. Consulting firms often emphasize the importance of this review process, highlighting that a failure to adequately address issues at this stage can lead to significant problems down the line, including increased costs and delayed market entry.

Once the prototype has been evaluated and refined, the next step is to develop a detailed production plan. This plan should outline every aspect of the production process, from sourcing materials to final assembly. It's important to establish clear timelines, budget forecasts, and quality control measures. A well-structured plan serves as a roadmap, guiding the organization through the complexities of scaling up production. Consulting experts often provide frameworks and templates to help organizations develop these plans, ensuring they are comprehensive and aligned with industry best practices.

Strategic Sourcing and Supplier Management

Strategic sourcing is a critical component of transitioning from prototype to production. Identifying and securing reliable suppliers for the necessary components and materials is essential for maintaining quality and meeting production deadlines. Organizations should conduct thorough market research to evaluate potential suppliers, considering factors such as cost, quality, and reliability. Developing strong relationships with suppliers can also lead to more favorable terms and conditions, which can significantly impact the overall project budget.

Negotiating contracts with suppliers is another crucial step. These contracts should clearly outline expectations regarding quality, delivery schedules, and payment terms. It's also wise to plan for contingencies, such as supply chain disruptions, by identifying alternative suppliers or materials. Consulting firms often assist organizations in this process, leveraging their extensive networks and expertise in supplier management to secure the best possible outcomes.

Moreover, implementing a robust quality control system is paramount. As production scales up, maintaining the quality of the prototype can become increasingly challenging. Organizations must establish strict quality control protocols and conduct regular audits of their suppliers to ensure that components meet the required standards. This proactive approach to quality management can prevent costly recalls and damage to the organization's reputation.

Scaling Production and Operational Excellence

Scaling production requires meticulous planning and execution. Organizations must carefully balance the need to increase production volumes with the imperative to maintain high quality and control costs. This often involves investing in new manufacturing technologies or processes that can enhance efficiency and output. For example, adopting automation or lean manufacturing techniques can significantly reduce production times and minimize waste, leading to lower costs and higher margins.