Inventory at Multiple Locations Tracker (Excel XLSX)

Excel (XLSX) + Zip archive file (ZIP)

VIDEO DEMO

INVENTORY MANAGEMENT EXCEL DESCRIPTION

This is a way to track the value and count of units of inventory and balances at a warehouse and at multiple locations (up to 500 total). The data entry is generic and straightforward so it can be compatible with nearly any inventory management use case that has to keep track of where inventory is and how much.

Inventory movements happen with a transaction entry. Those entries are moved with the push of a button to a database tab (editable if you make a data entry error). The database tab is queried with formulas in order to show automated reports about where the inventory is and how much is at the warehouse / locations as well as monthly movements over time.

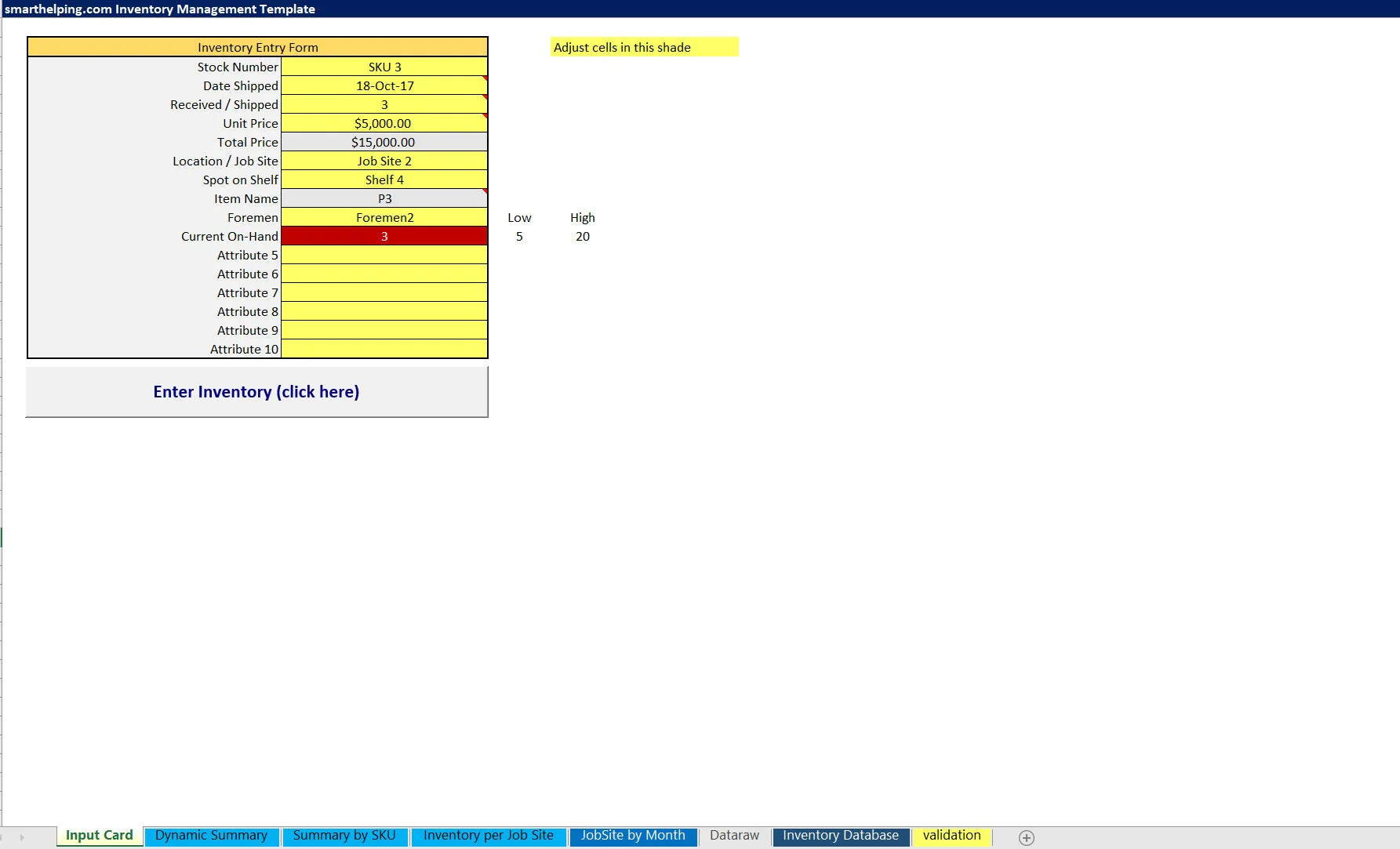

Input Data:

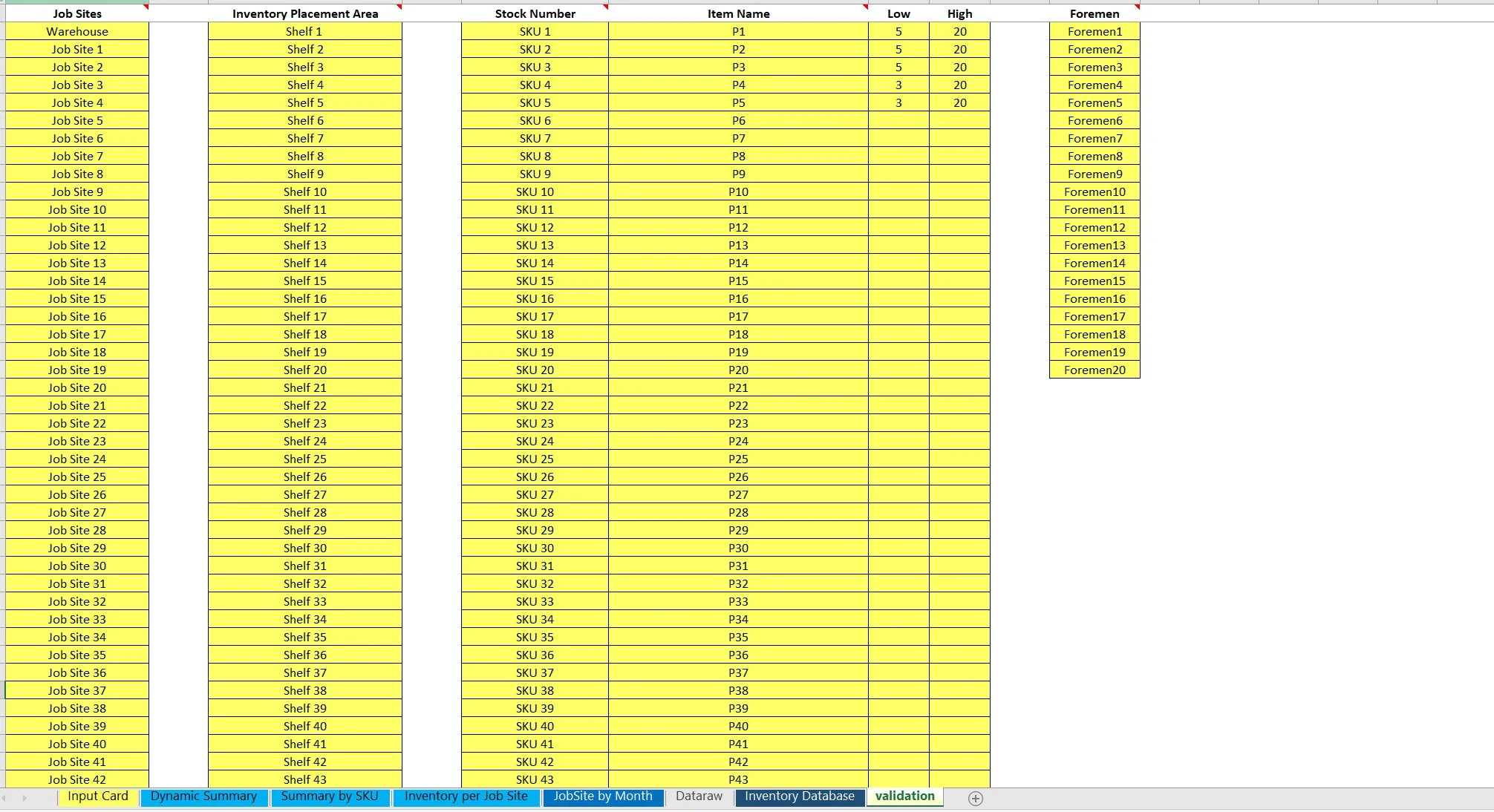

• Stock Number (dropdown per defined validation lists)

• Date Shipped

• # of Units Received / Shipped Unit Price

• Total Price

• Location / Job Site (dropdown per defined validation lists)

• Spot on Shelf (dropdown per defined validation lists)

• Item Name (automated formula based on defined names for each SKU on the validation tab)

• Foremen (dropdown)

• Current On-Hand (formula based on real-time data prior to inventory transaction at hand)

• Attribute 5

• Attribute 6

• Attribute 7

• Attribute 8

• Attribute 9

• Attribute 10

There are multiple summary tabs that let the user dive deeper into what has happened with inventory.

Reports include:

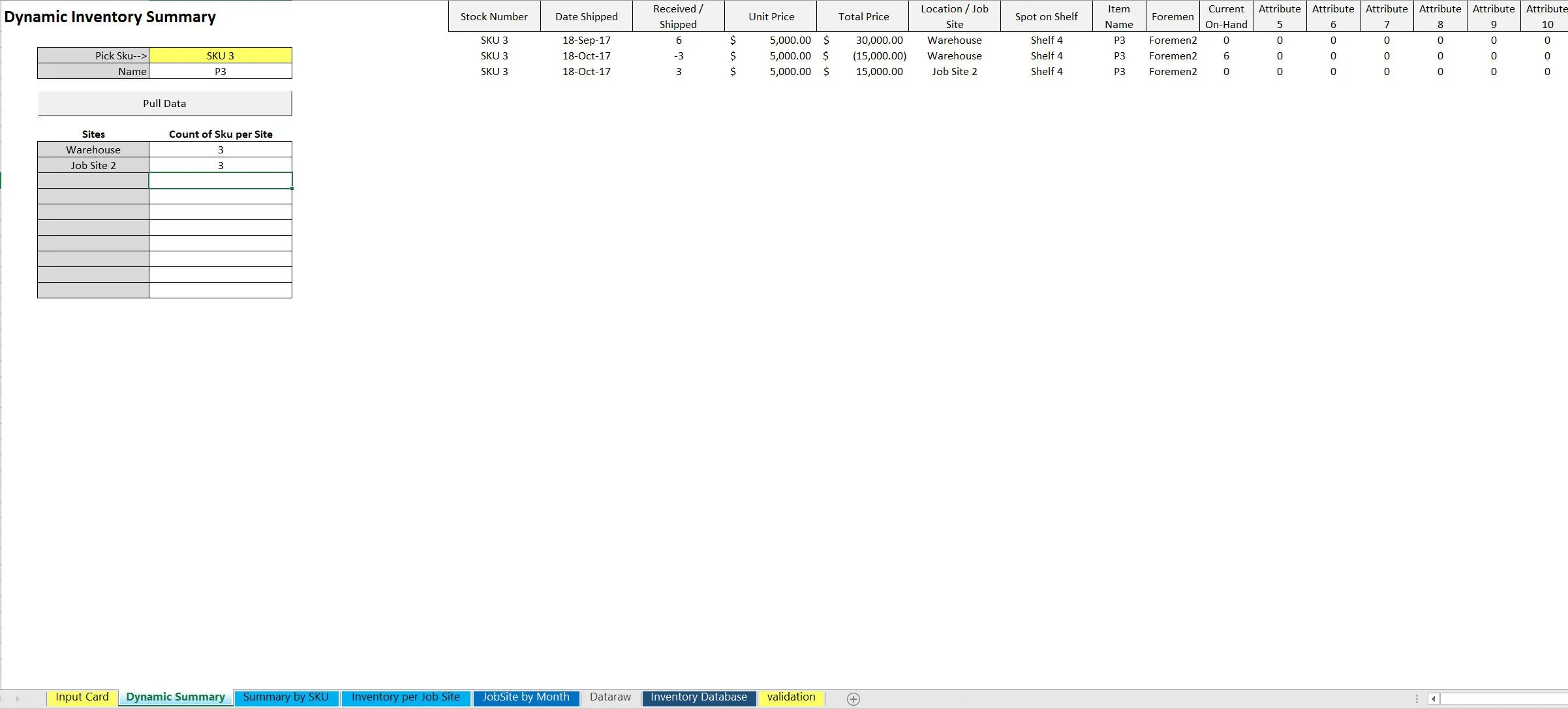

Dynamic Summary – Users can pick a SKU / Stock Item and then hit the ‘Pull Data' button to see all transactions that have happened for that SKU as well as the count of units that are at the warehouse / up to 9 other locations at once. If you want to report the inventory balance at more locations, the formulas can simply be pulled down on this tab as far as you want.

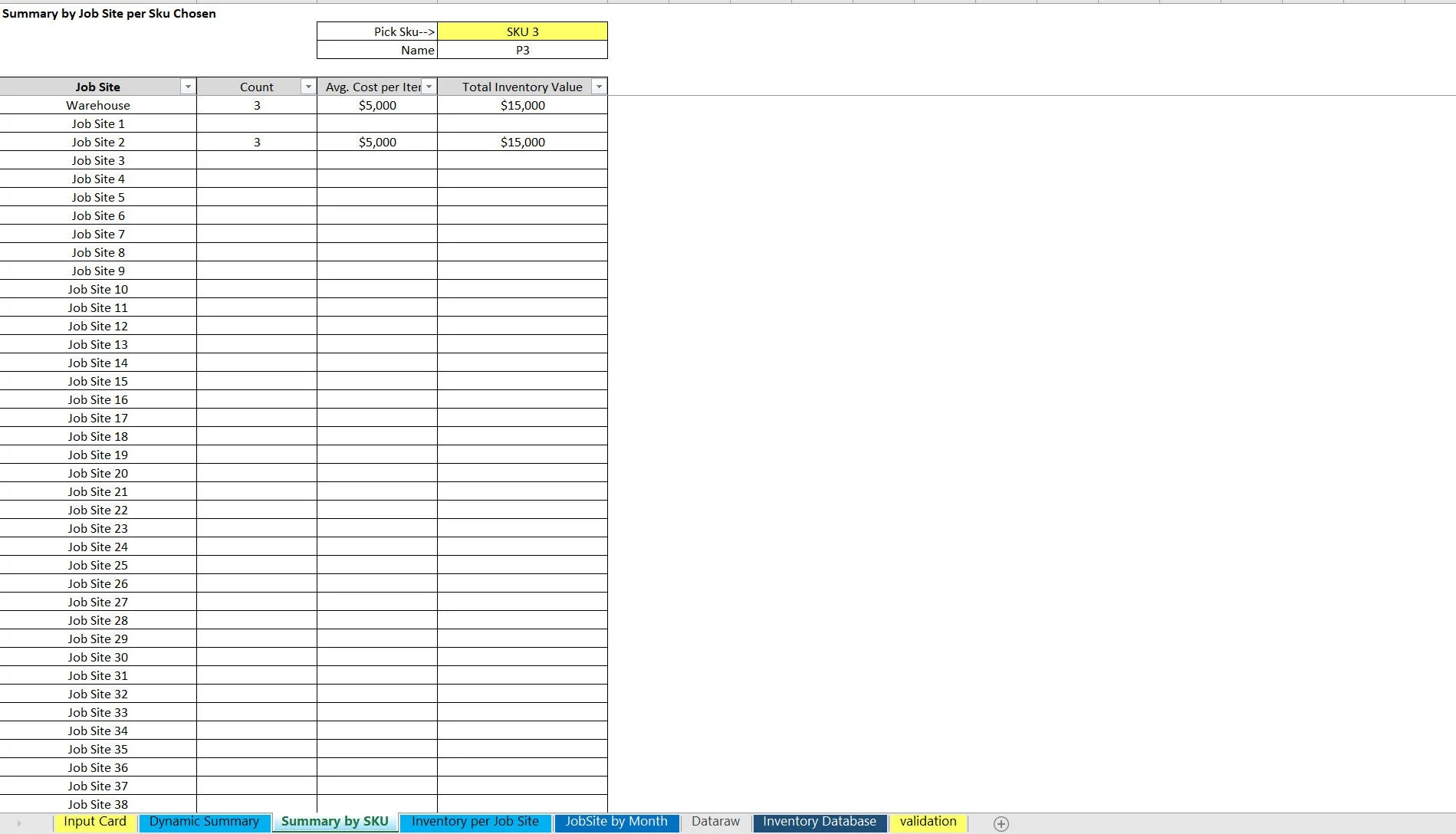

Summary by SKU – This is a static report that shows all 500 locations and based on the SKU selected, it will show the total units, value per unit, and total value of that inventory at each location.

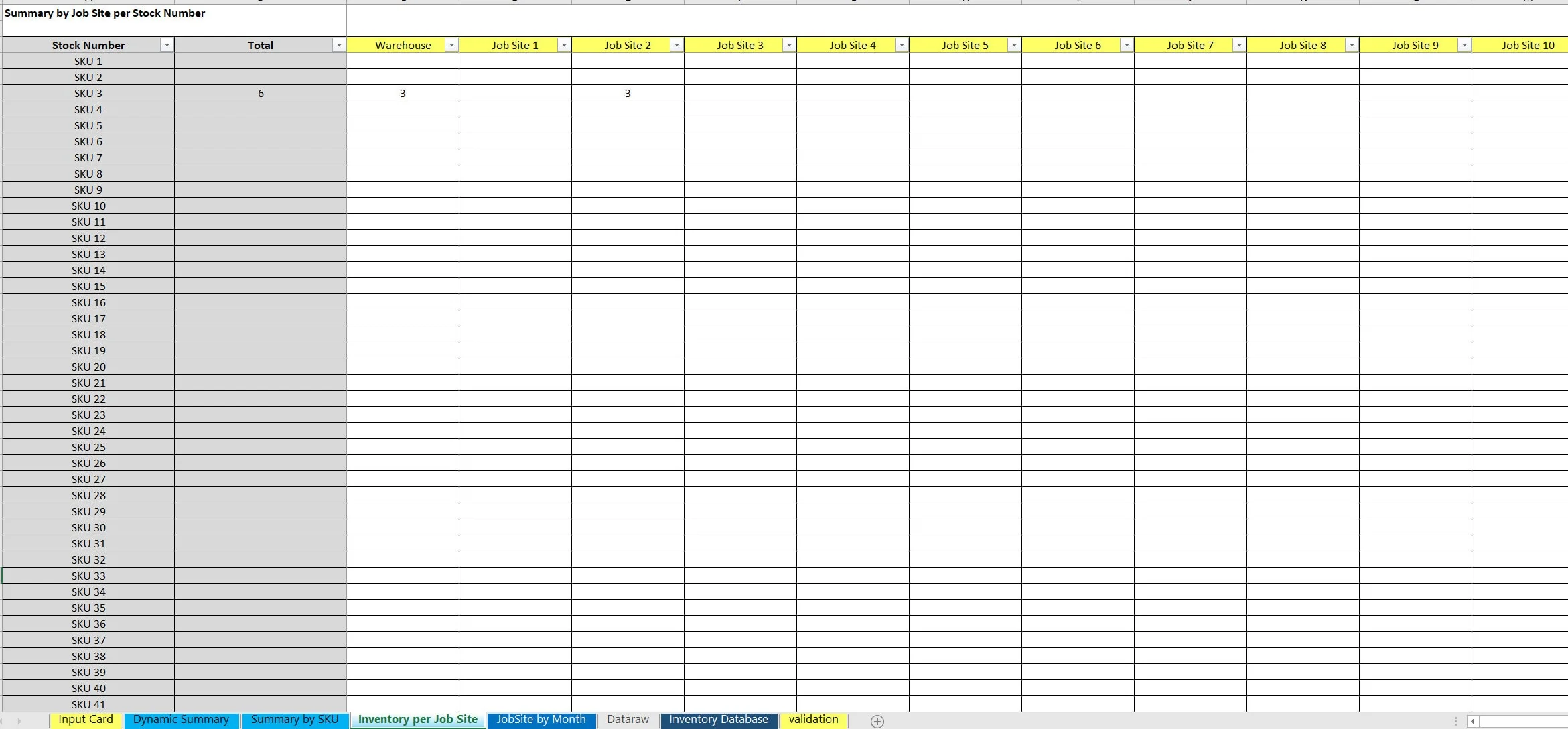

Inventory per Job Site – This lets the user see a cross section of every single SKU and the # of units of each SKU that are in up to 20 locations. The user can report on more than 20 locations by dragging the formulas over to more columns and adding location names to row 3 if desired.

Job Site by Month – This shows a running monthly summary by SKU for a selected location for up to 68 months at once. Be sure not to change any of the tab names as that will break the Macro.

Also, the most important tab is probably the ‘inventory per job site' tab as that will give you a full picture of inventory. If you use more than 20 locations, the formulas are really easy to expand. Just highlight the given row all the way down to the last SKU and then drag the formulas over to account for as many jobs sites as you use.

This was limited to 20 initially so the file was not too big, but it is still workable if you want to report on all SKUS across all 500 locations.

Got a question about the product? Email us at support@flevy.com or ask the author directly by using the "Ask the Author a Question" form. If you cannot view the preview above this document description, go here to view the large preview instead.

Source: Best Practices in Inventory Management Excel: Inventory at Multiple Locations Tracker Excel (XLSX) Spreadsheet, Jason Varner | SmartHelping