Made to Order Manufacturing Financial Model (Excel XLSX)

Excel (XLSX) + Excel (XLSX)

VIDEO DEMO

BENEFITS OF THIS EXCEL DOCUMENT

- Cash flow forecasting with AR and AP detail.

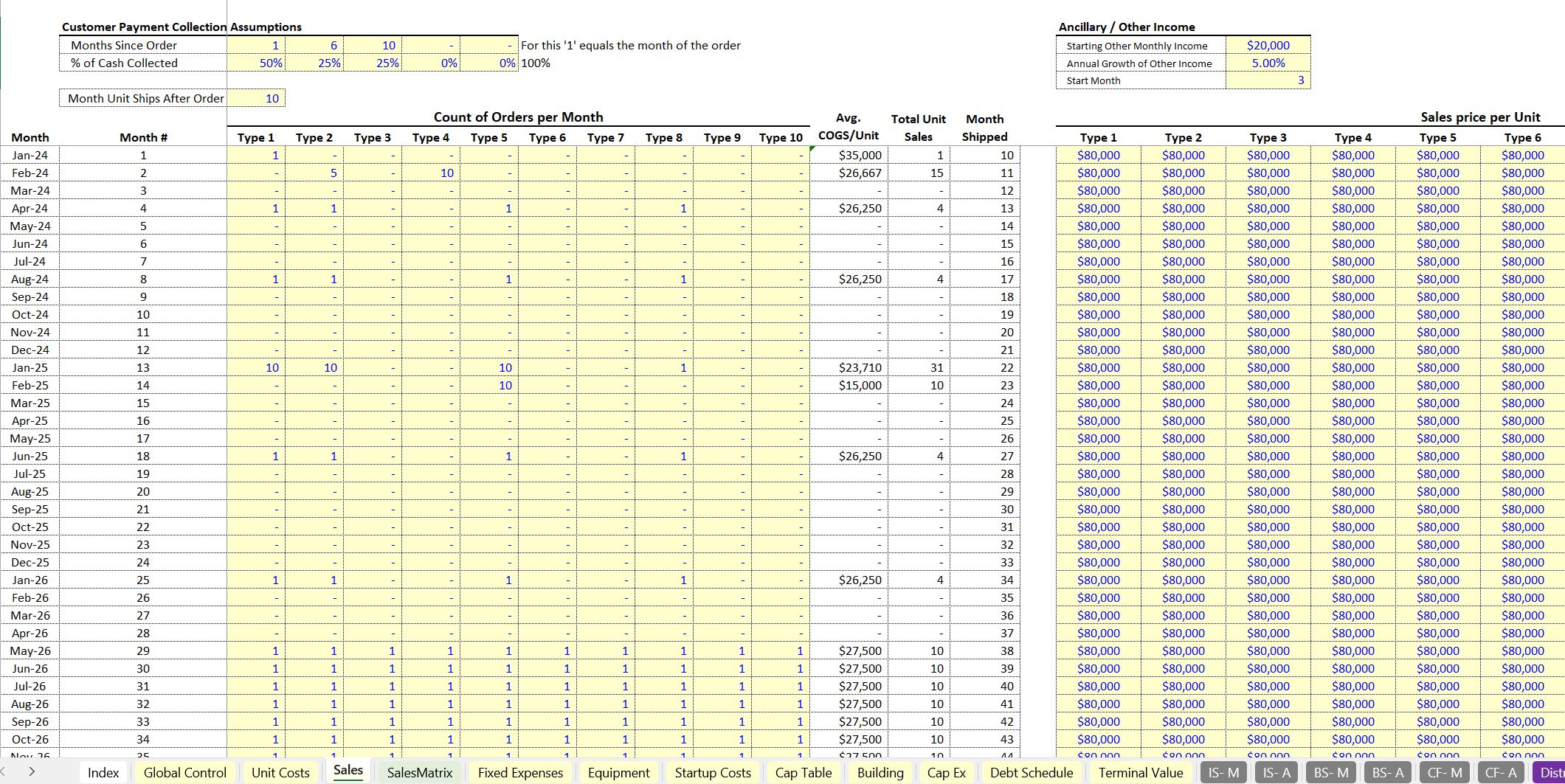

- Dynamic order demand schedule for up to 10 product categories.

MANUFACTURING EXCEL DESCRIPTION

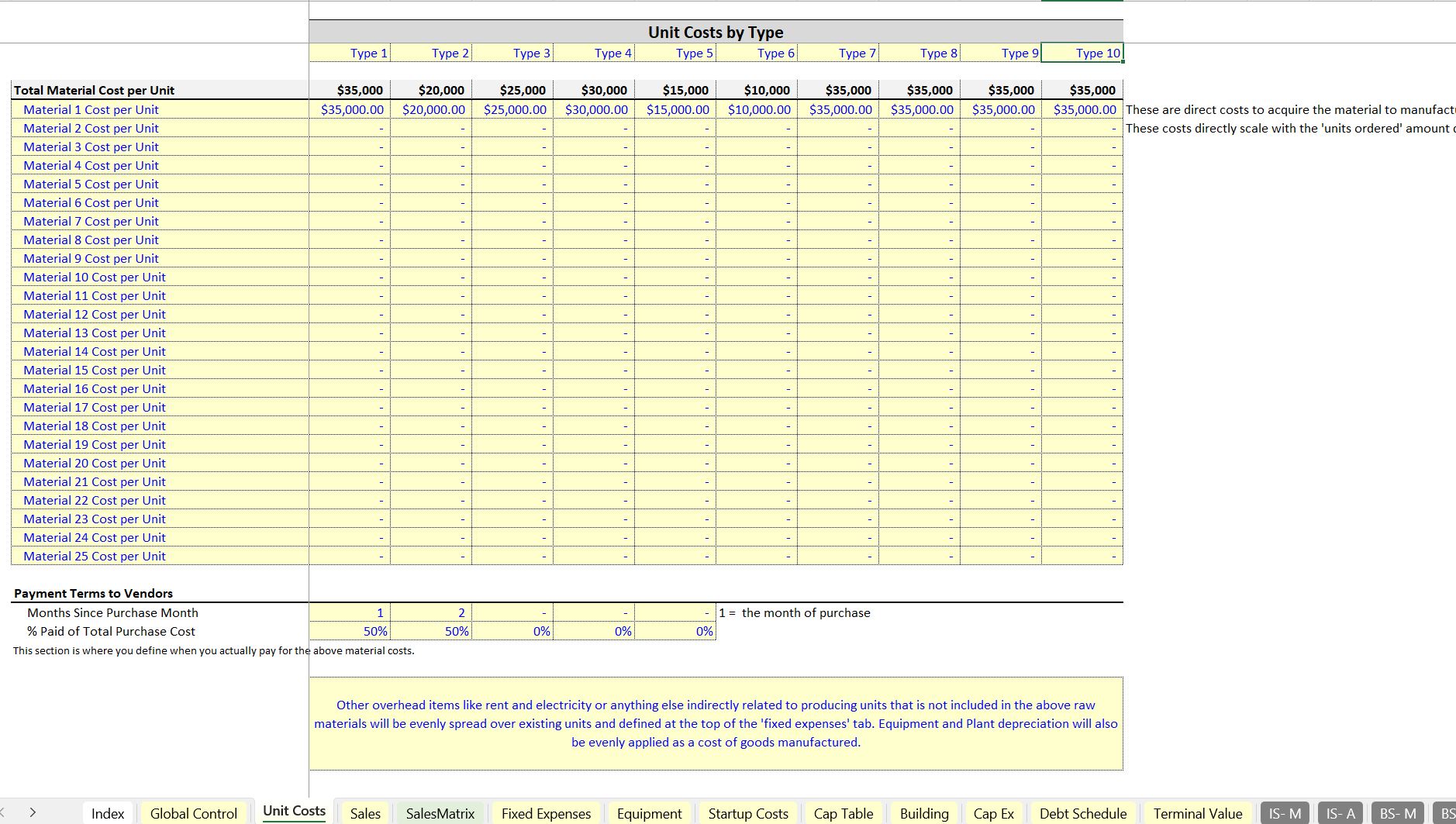

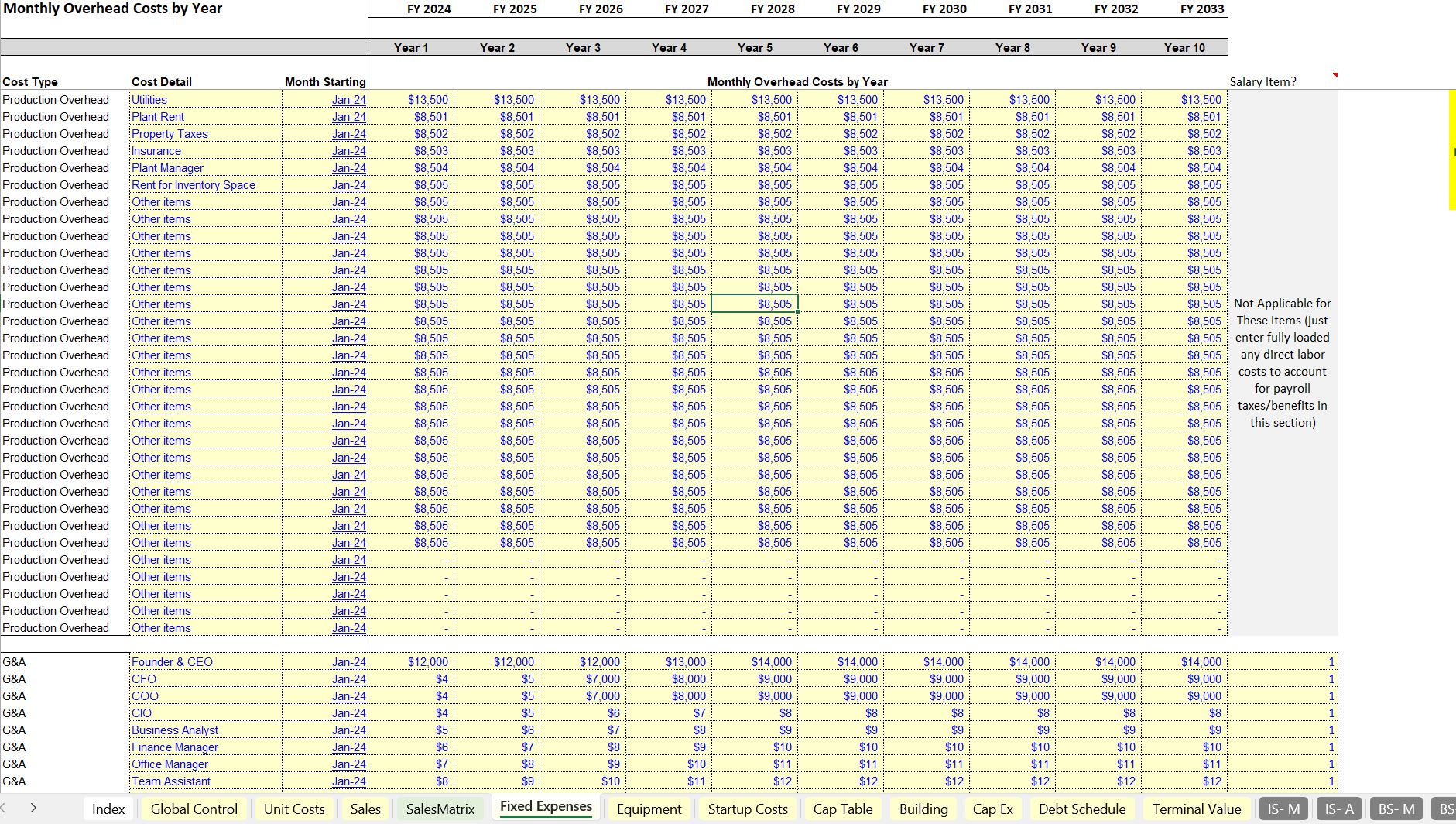

Recent Update: Added two new cost per unit sections for direct labor and variable manufacturing overhead.

Update: Added a line of credit module and an alternative version that has some more automation around future pricing per unit type and expenses over time.

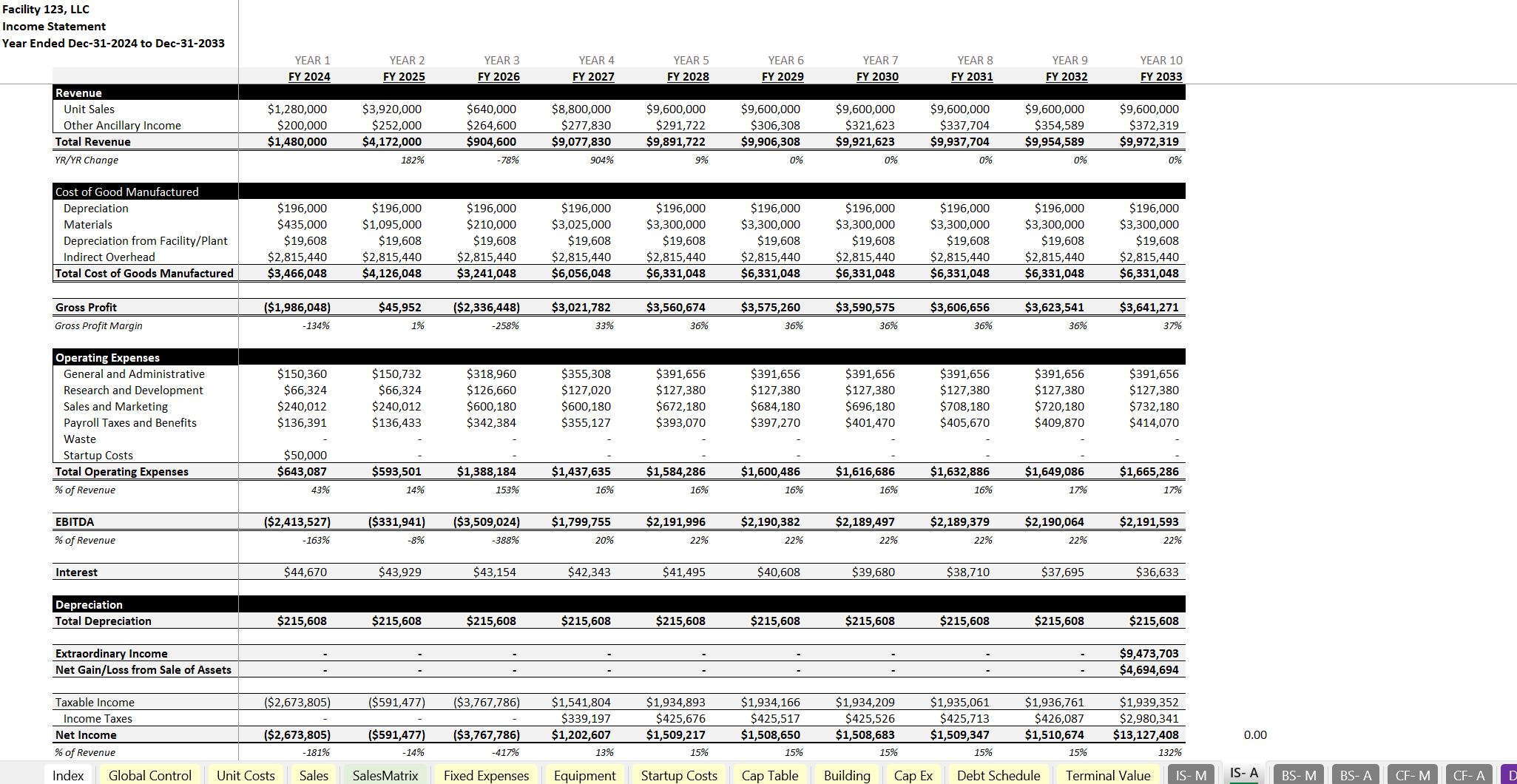

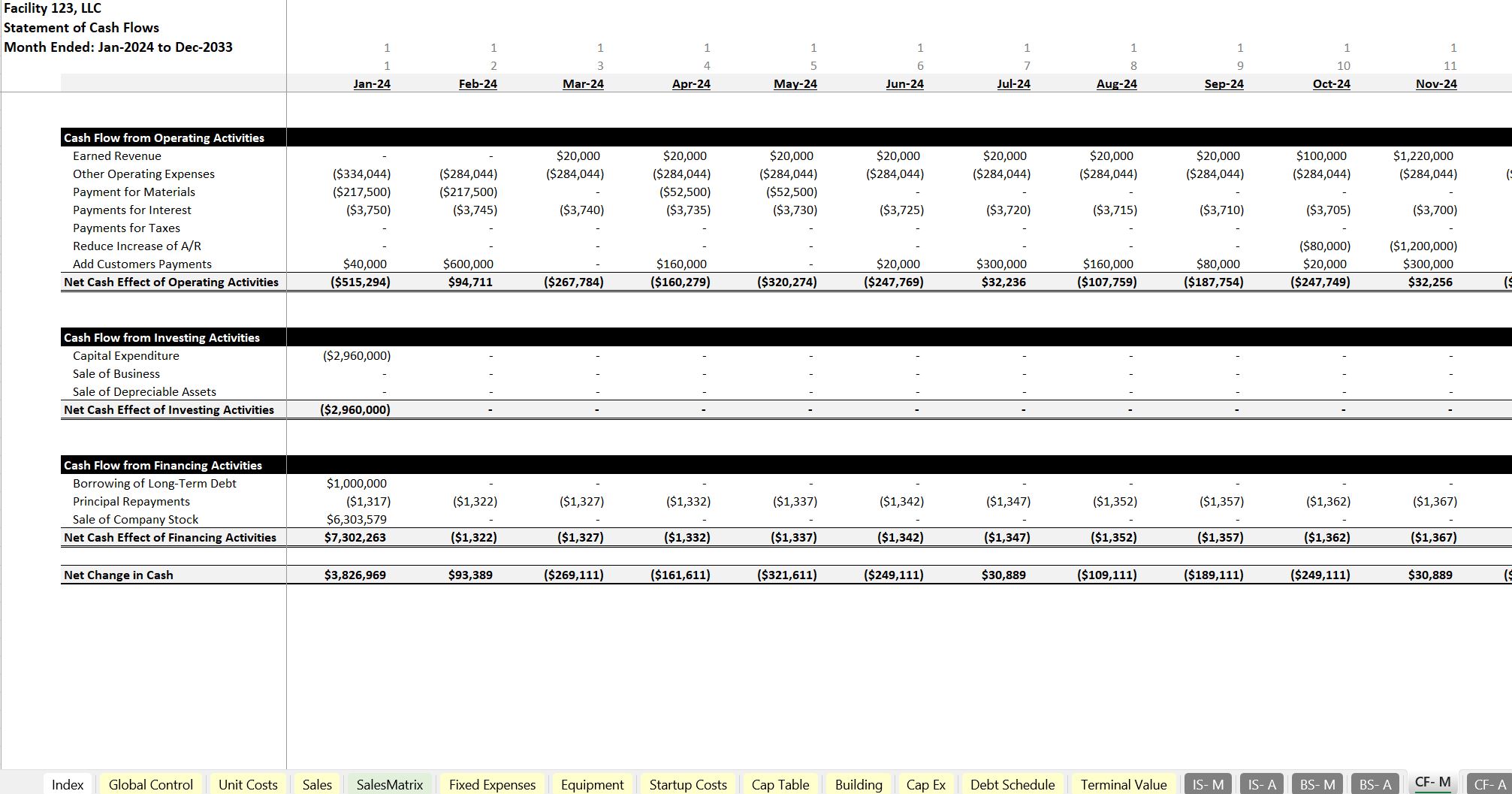

Bespoke or made-to-order manufacturing businesses touch on all sorts of industries. Building custom low volume items involve some important financial planning nuances. Cash flow management is a big one. You want to make sure you have enough money from the customer to get started but do what to offer favorable terms as well.

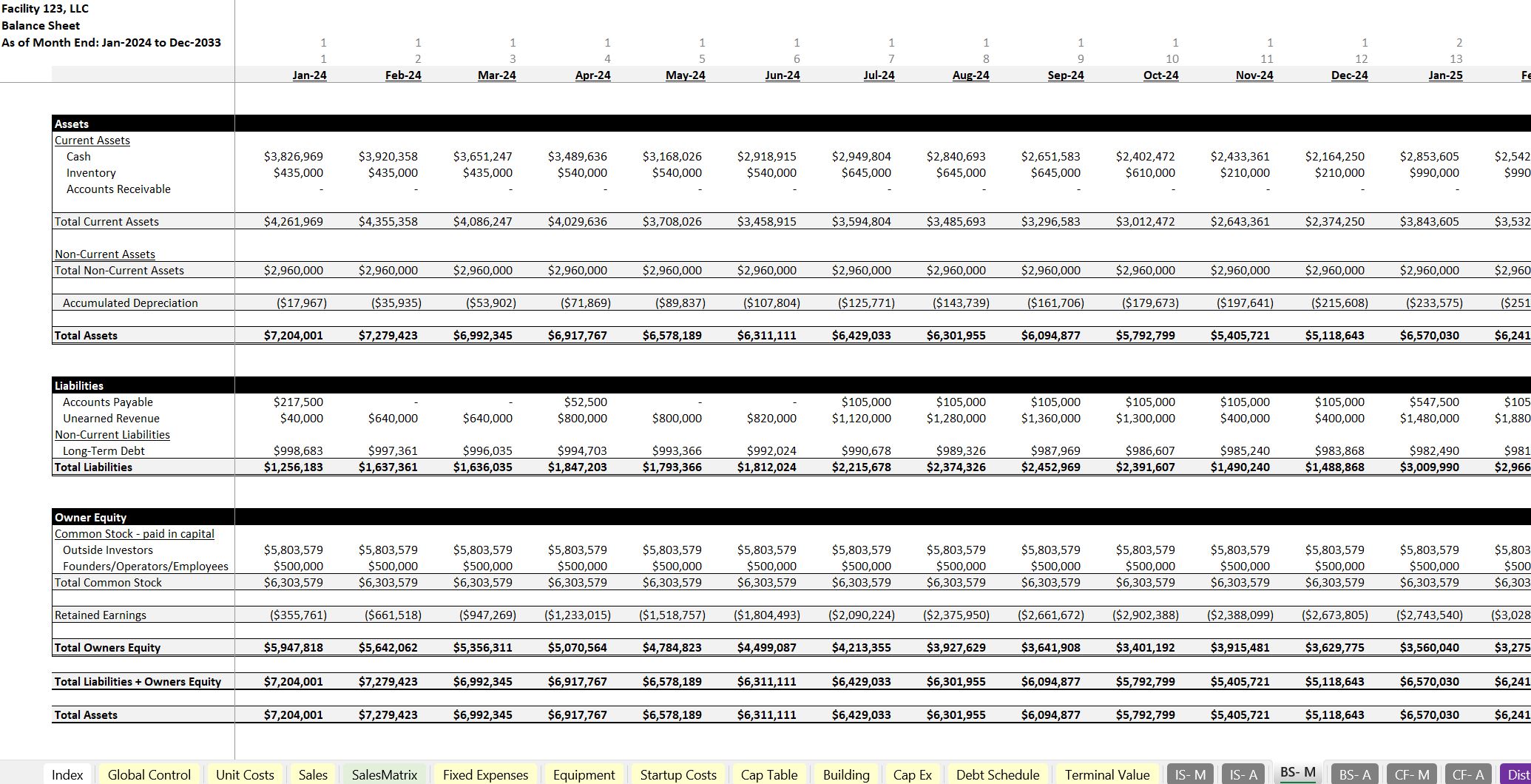

You will also need to negotiate payable terms for buying resources to manufacture with. These are all aspects that go into a comprehensive manufacturing forecasting model. This template was built to handle all the cash flow and accrual accounting logic effects of these types of cycles.

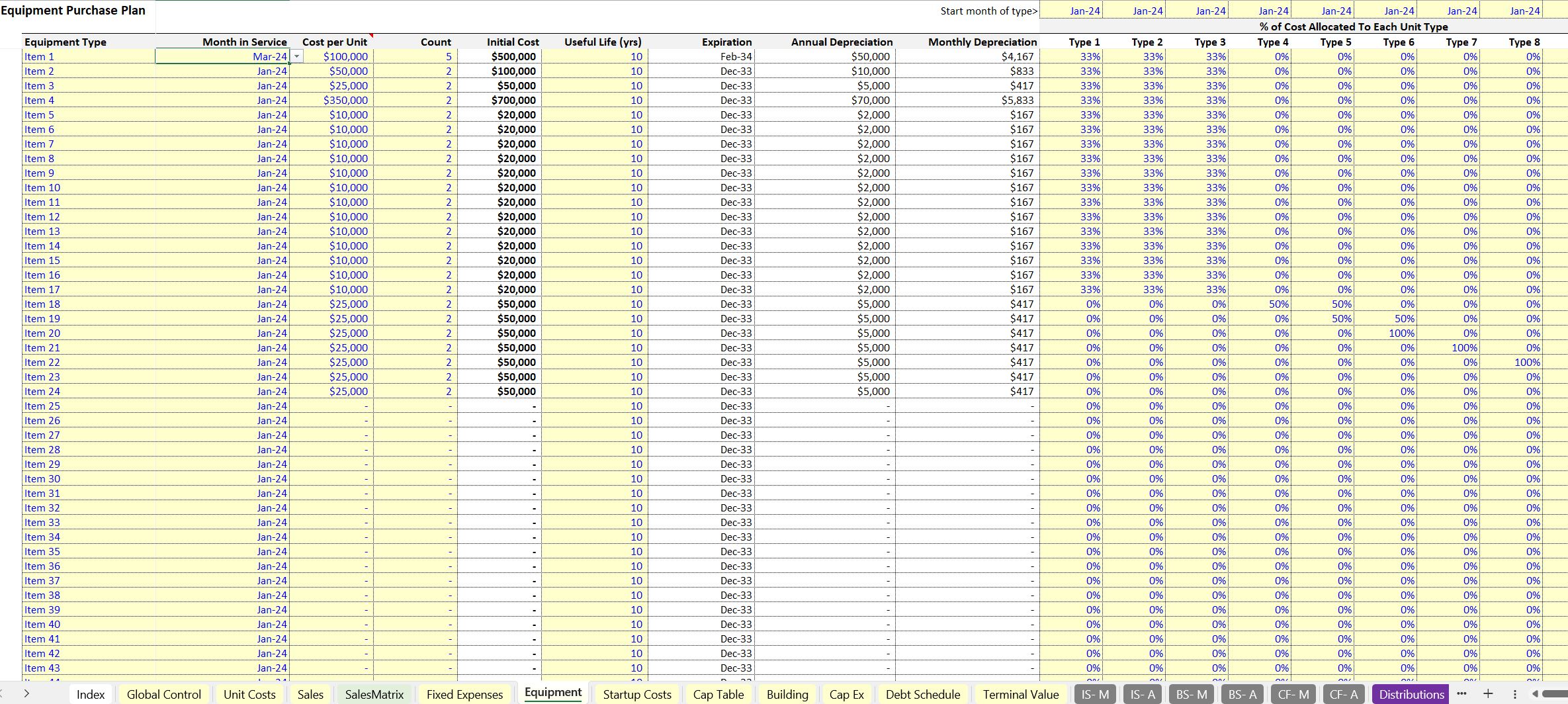

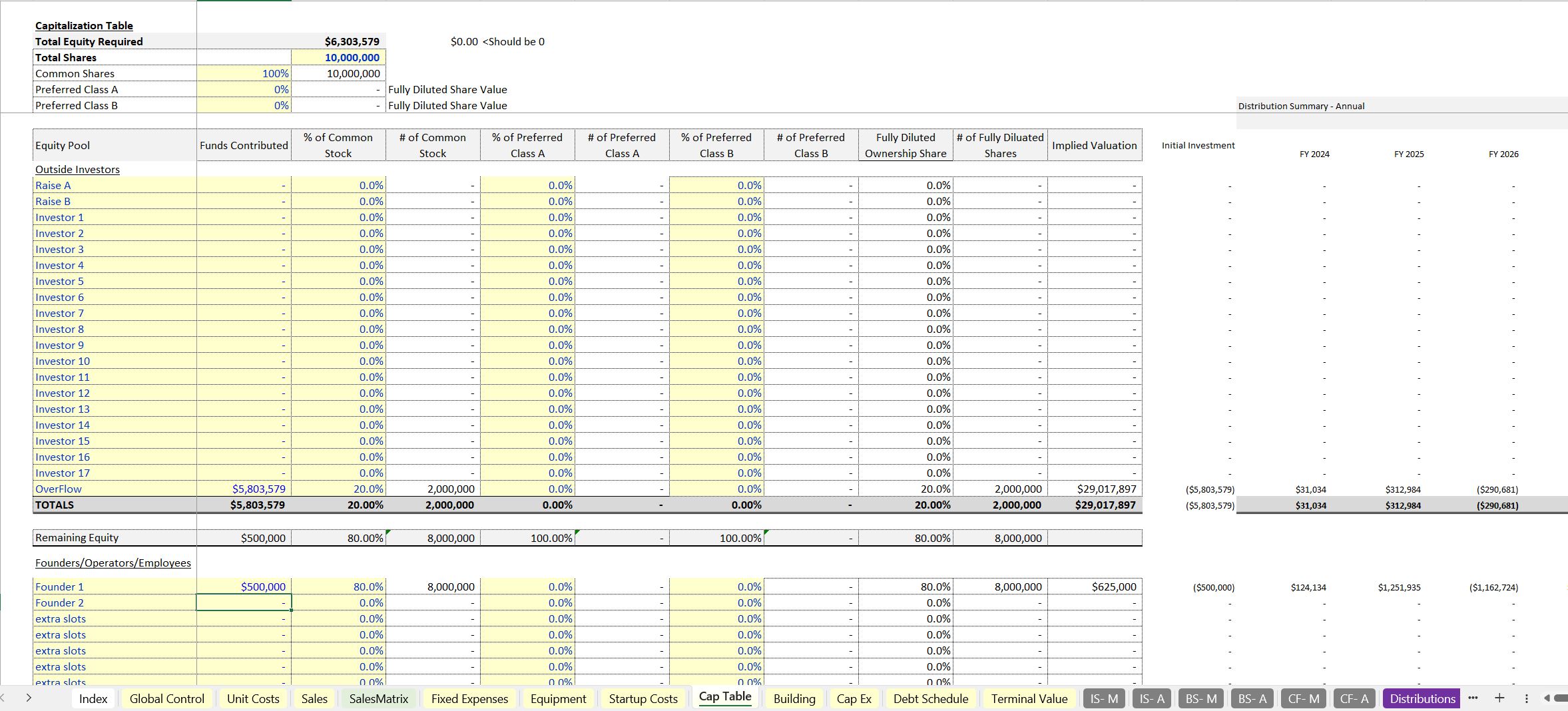

Depending on exactly how the assumptions are configured, the user will have the potential for unearned revenue, accounts receivable, accounts payable, inventory, cost of goods sold, and more. There is full control over the collection of cash from customers and when the orders ship relative to an ordering schedule.

Up to 10 product categories can be modeled and the number of orders can be defined by month for up to 120 months. In each month, the sales price can be adjusted for each type. All aspects of the model are driven off the order counts and timing therein.

Here are some reasons why investors and operators like this kind of manufacturing business:

Customization: Made-to-order manufacturing allows customers to customize products according to their specific requirements. This level of personalization can lead to higher customer satisfaction and loyalty as they receive products tailored to their unique needs.

Flexibility: With made-to-order manufacturing, businesses can be more flexible in adapting to changing customer demands and market trends. They can quickly adjust their production processes and respond to individual customer requests, making it easier to meet evolving consumer preferences.

Reduced inventory costs: Since made-to-order manufacturing focuses on producing goods based on customer orders, there is less need for maintaining large inventories. This can help reduce inventory holding costs and the risk of excess inventory becoming obsolete or unsold.

Improved efficiency: Made-to-order manufacturing can lead to improved operational efficiency. By aligning production with actual customer demand, businesses can minimize waste, optimize resource allocation, and streamline their manufacturing processes. This can result in cost savings and increased productivity.

Competitive advantage: Offering made-to-order products can give businesses a competitive edge in the market. It allows them to differentiate themselves from competitors who may offer only standard, off-the-shelf products. Customization can be a valuable selling point and attract customers who value personalized experiences.

Higher profit margins: Made-to-order manufacturing often involves charging premium prices for customized products. Customers are typically willing to pay more for personalized items that meet their specific needs. As a result, businesses can potentially achieve higher profit margins compared to mass-produced goods.

Strong customer relationships: The made-to-order approach fosters closer relationships with customers. By engaging them in the design and customization process, businesses can build rapport and establish long-term connections. This can lead to repeat business, referrals, and positive word-of-mouth, further enhancing the company's reputation and customer base.

Market expansion opportunities: Custom manufacturing can open up new market segments and opportunities. By catering to niche markets or specific customer segments with unique requirements, businesses can tap into previously untapped markets and reach customers who may not find suitable options elsewhere.

It's important to note that while made-to-order manufacturing offers numerous benefits, it also presents certain challenges such as longer lead times, increased complexity in managing individual orders, and potentially higher production costs. Therefore, careful planning, efficient production processes, and effective communication with customers are essential for successfully running a made-to-order manufacturing business.

An instructional video is included in the file and there are two versions that come with the download. The primary file has dummy data filled in and the second is a blank version.

Got a question about the product? Email us at support@flevy.com or ask the author directly by using the "Ask the Author a Question" form. If you cannot view the preview above this document description, go here to view the large preview instead.

Source: Best Practices in Manufacturing, Integrated Financial Model Excel: Made to Order Manufacturing Financial Model Excel (XLSX) Spreadsheet, Jason Varner | SmartHelping