|

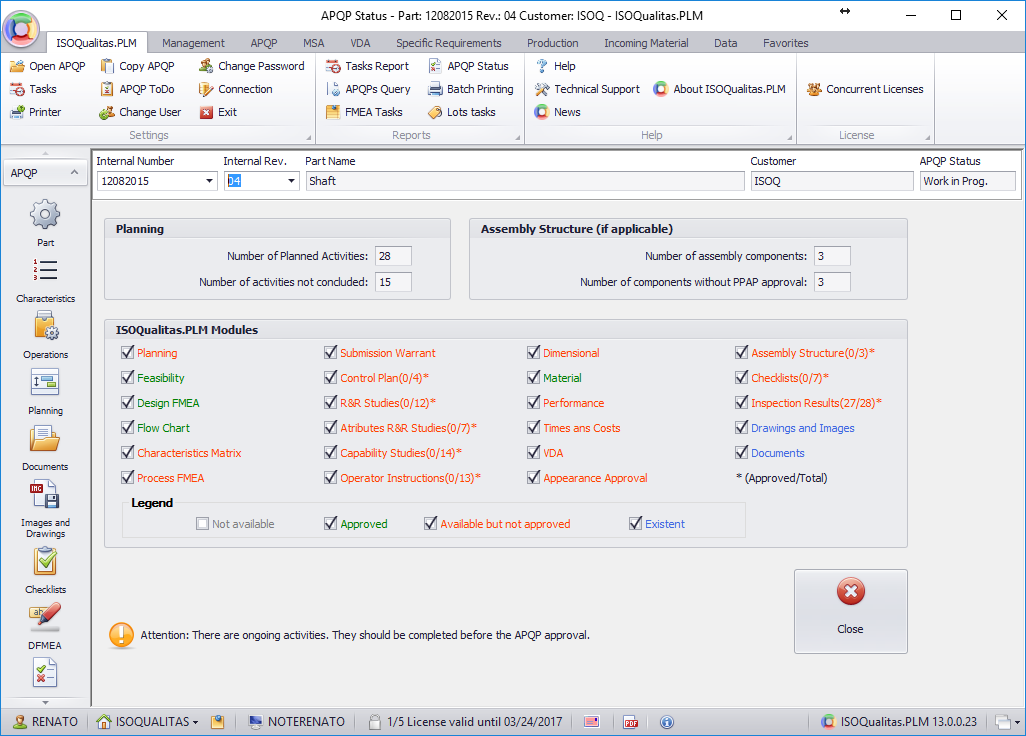

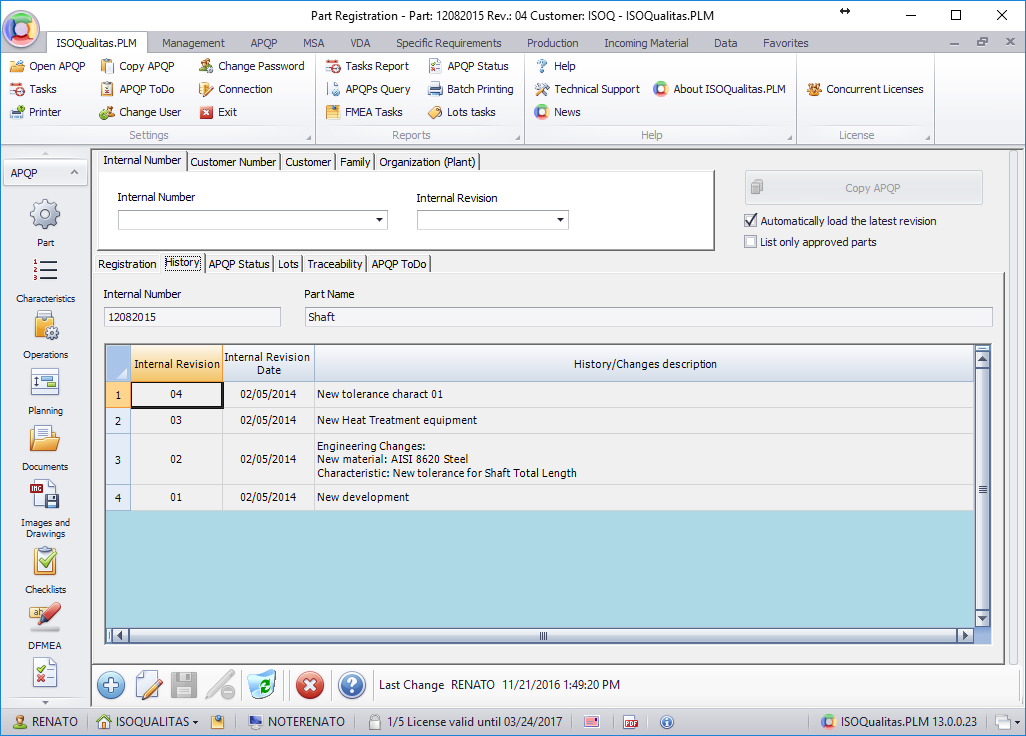

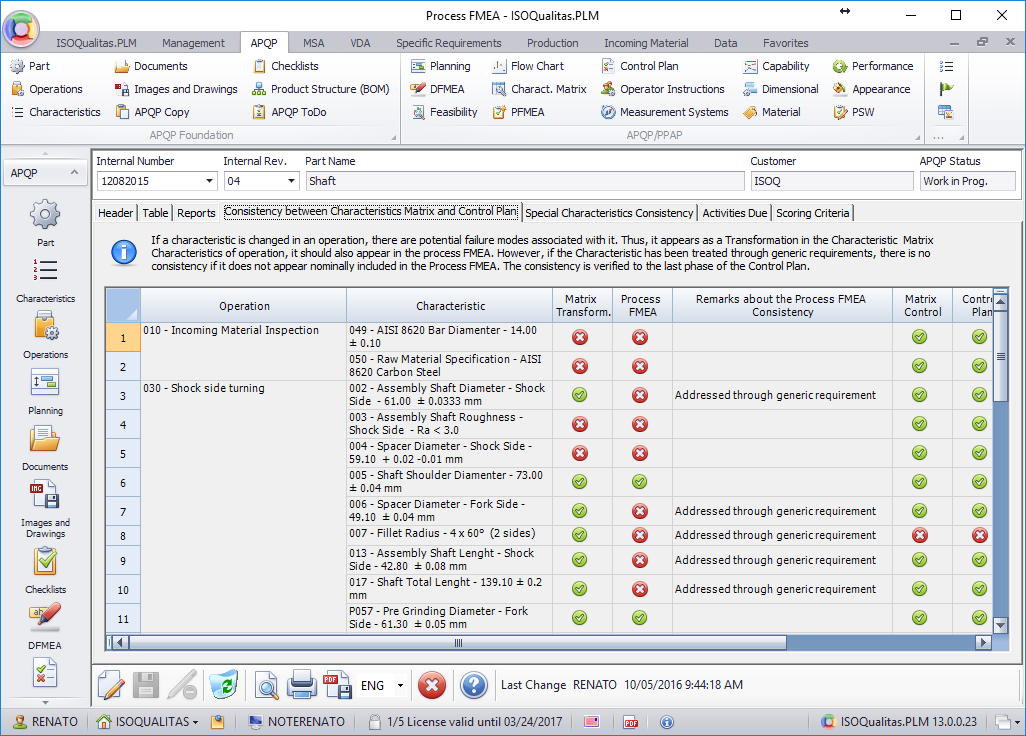

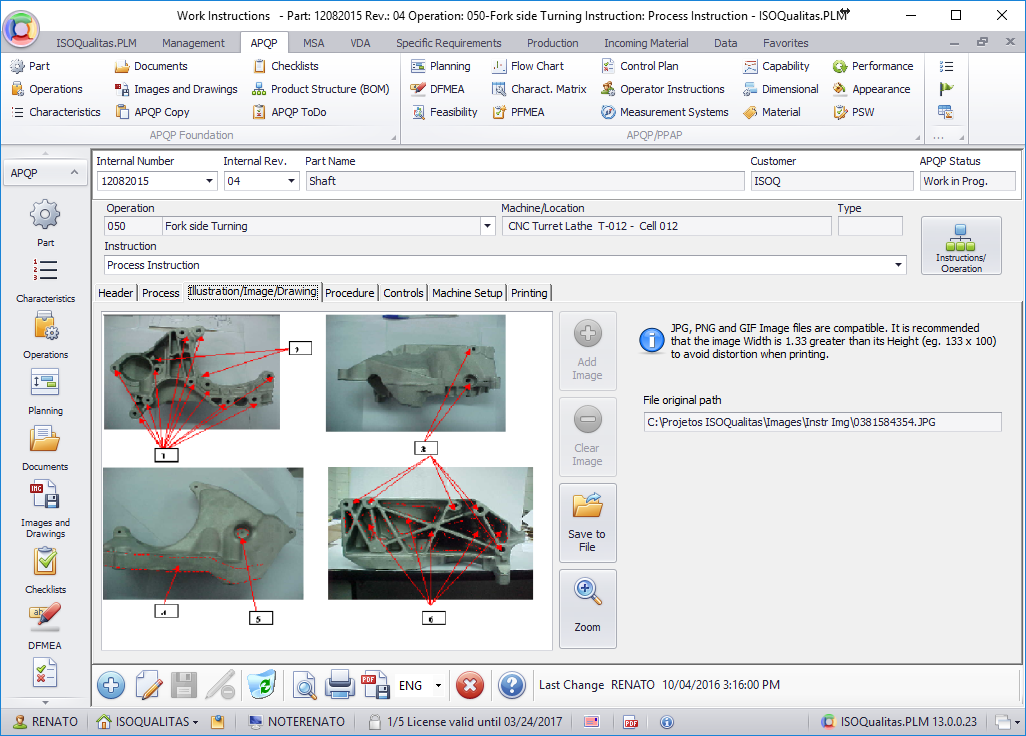

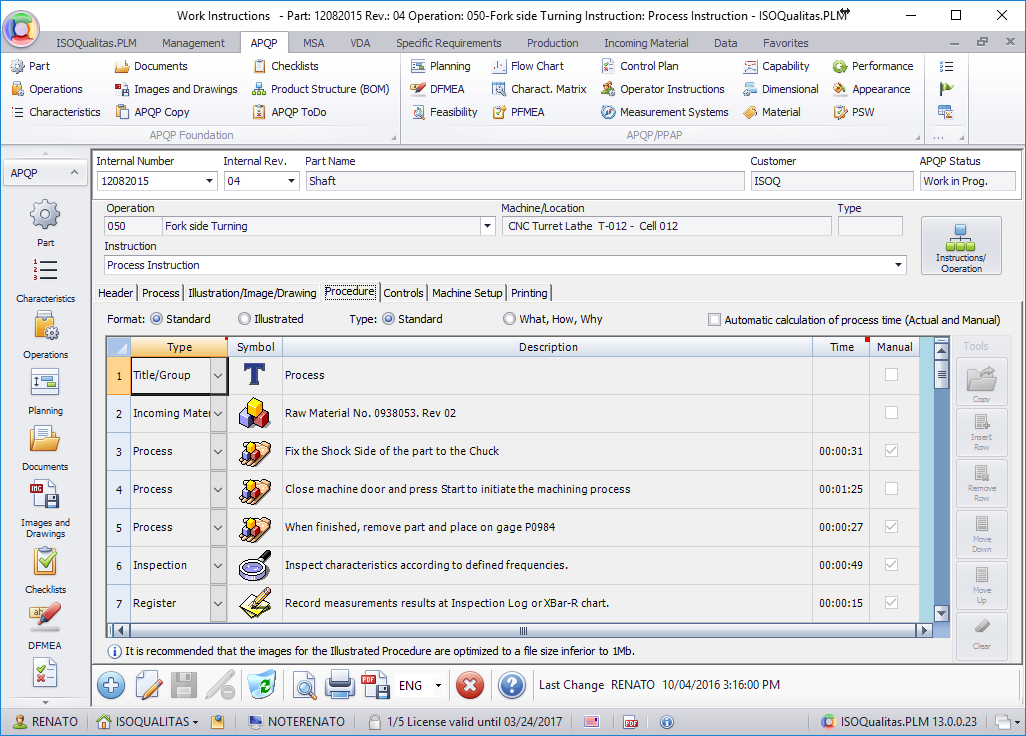

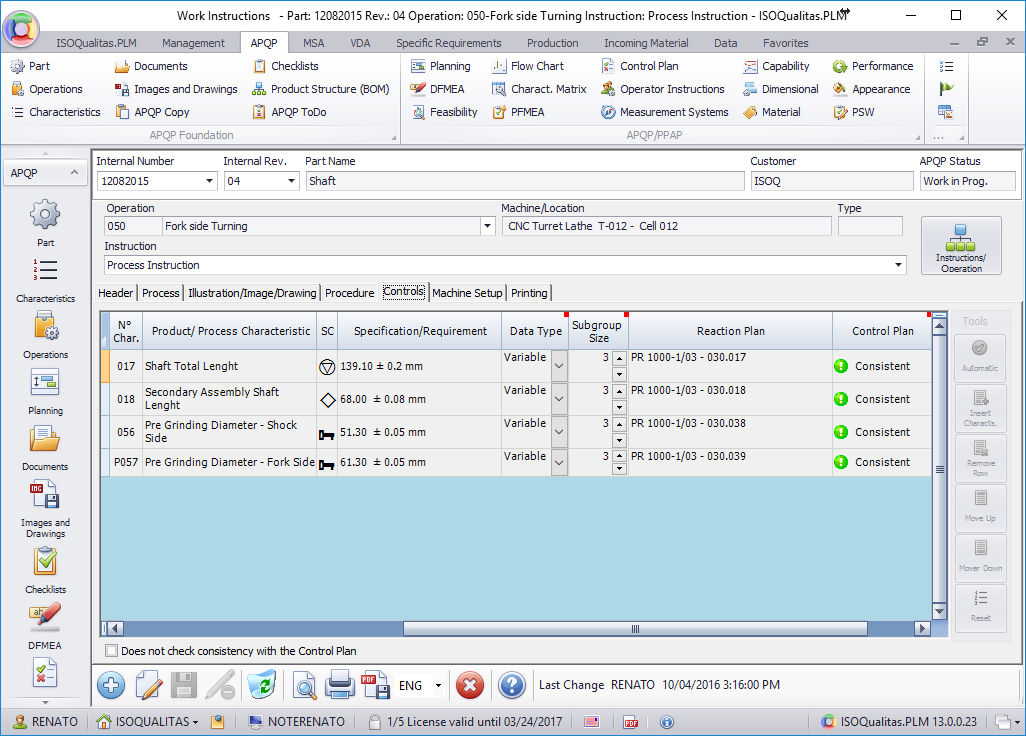

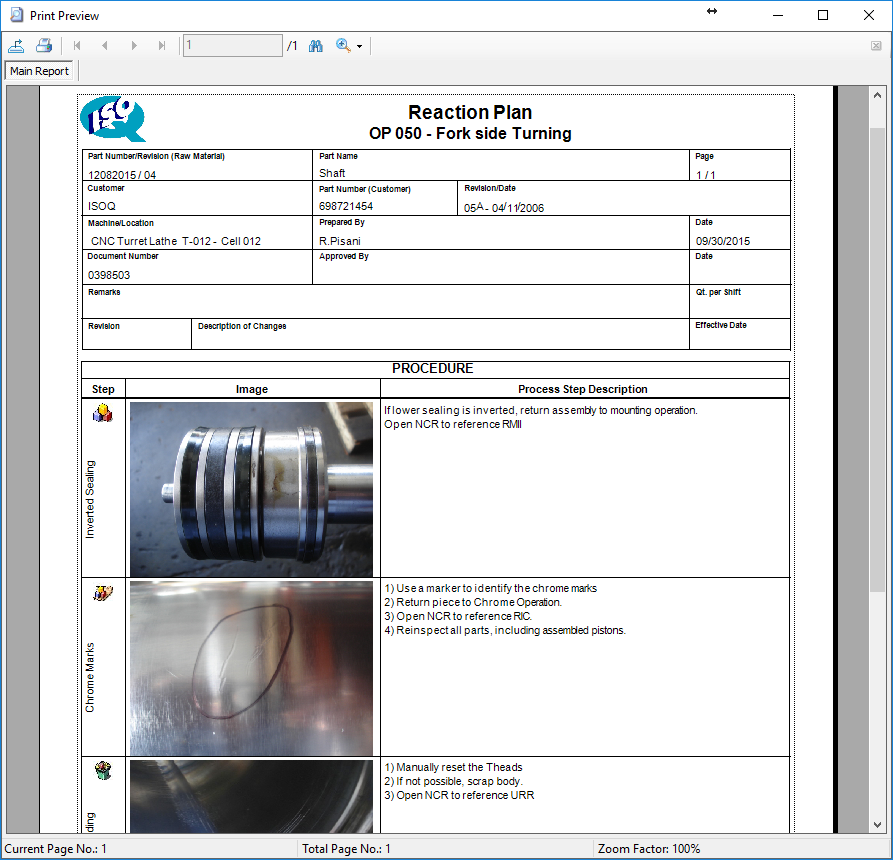

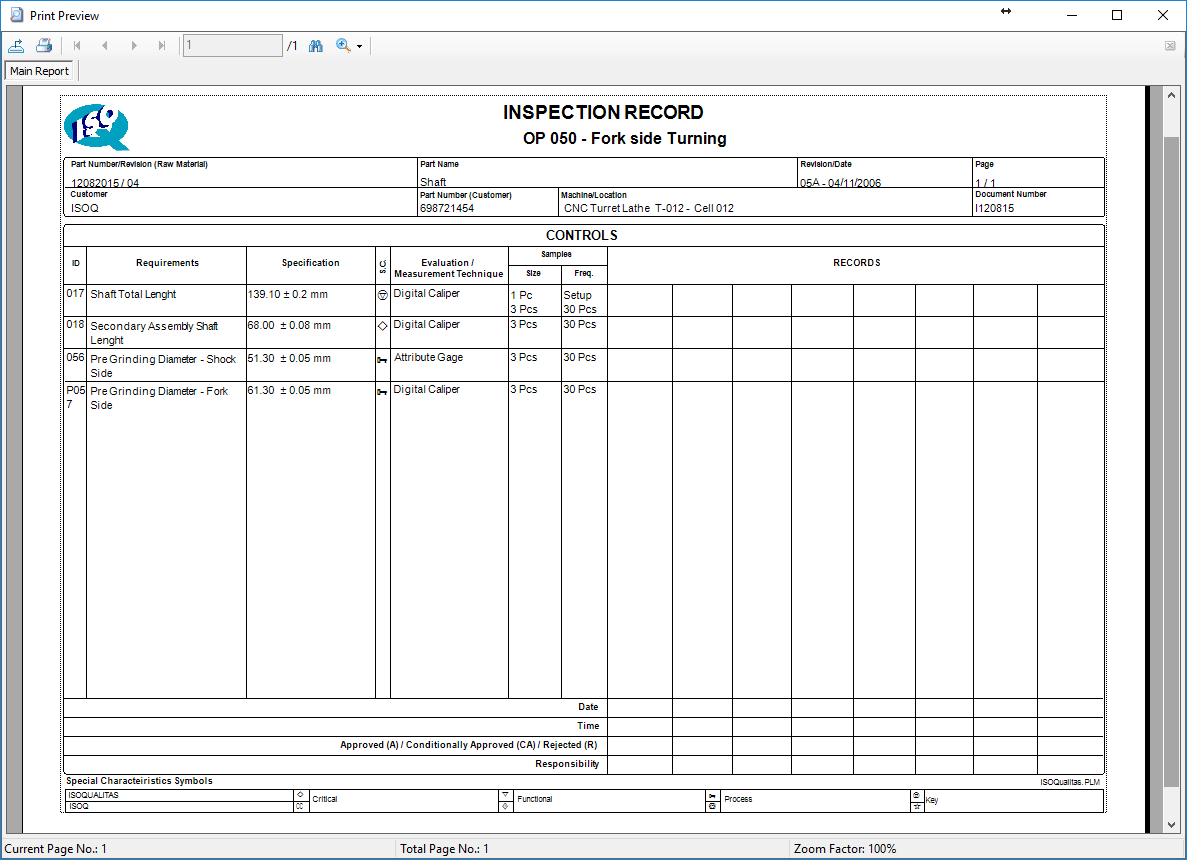

ISOQualitas.PLM is the flagship product for ISOQualitas. It is a comprehensive and integrated software that optimizes all Product Lifecycle Management activities—from Advanced Product Quality Planning (APQP), through the Production Part Approval Process (PPAP), and all the way to manufacturing with nonconformities and Corrective Action and Preventative Action (CAPA) management—according to the requirements and standards of the automotive industry. ISOQualitas.PLM is a tool that will enable an auto parts supplier to fully comply with quality management standards IATF-16949, VDA, EAQF and reference manuals APQP, PPAP, FMEA, SPC, MSA, VDA2, and others set by the automotive industry. Furthermore, ISOQualitas.PLM will also enable your company to meet specific requirements from global automotive manufacturers (Phased PPAP, QSB, Plan de Surveillance). Download the ISOQualitas.PLM product brochure here.

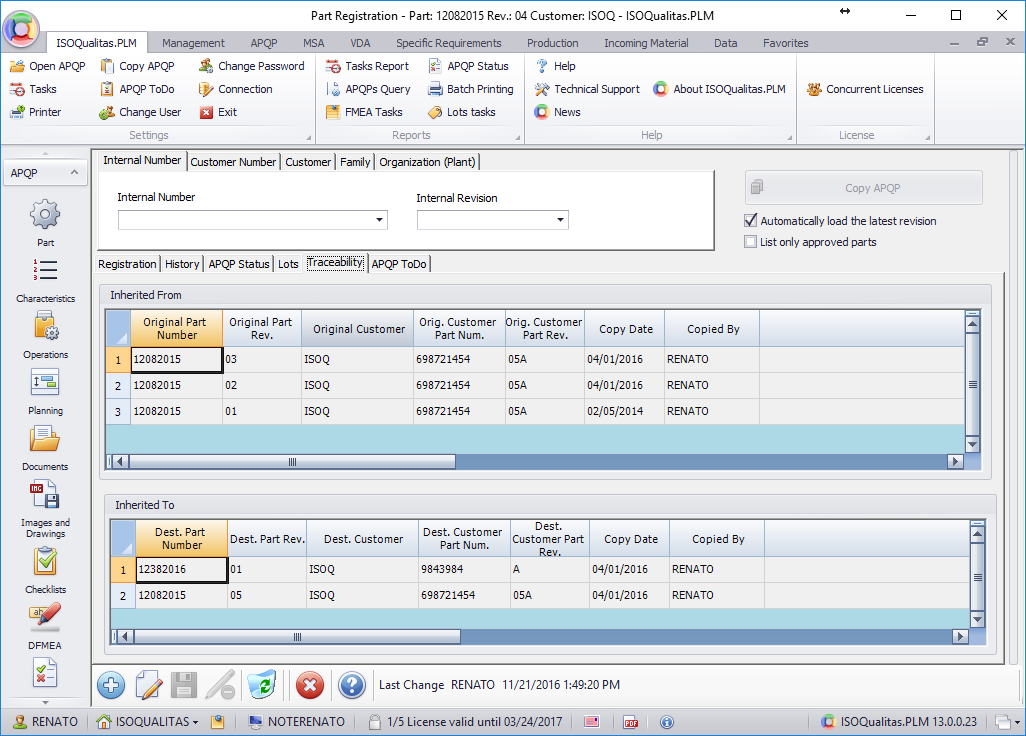

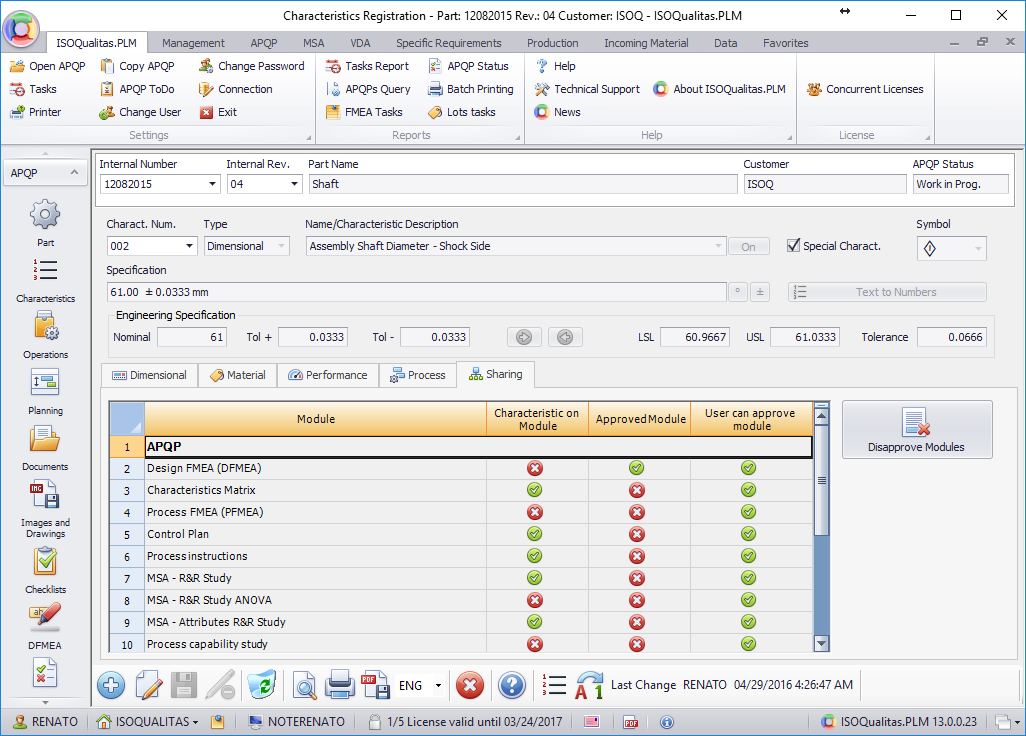

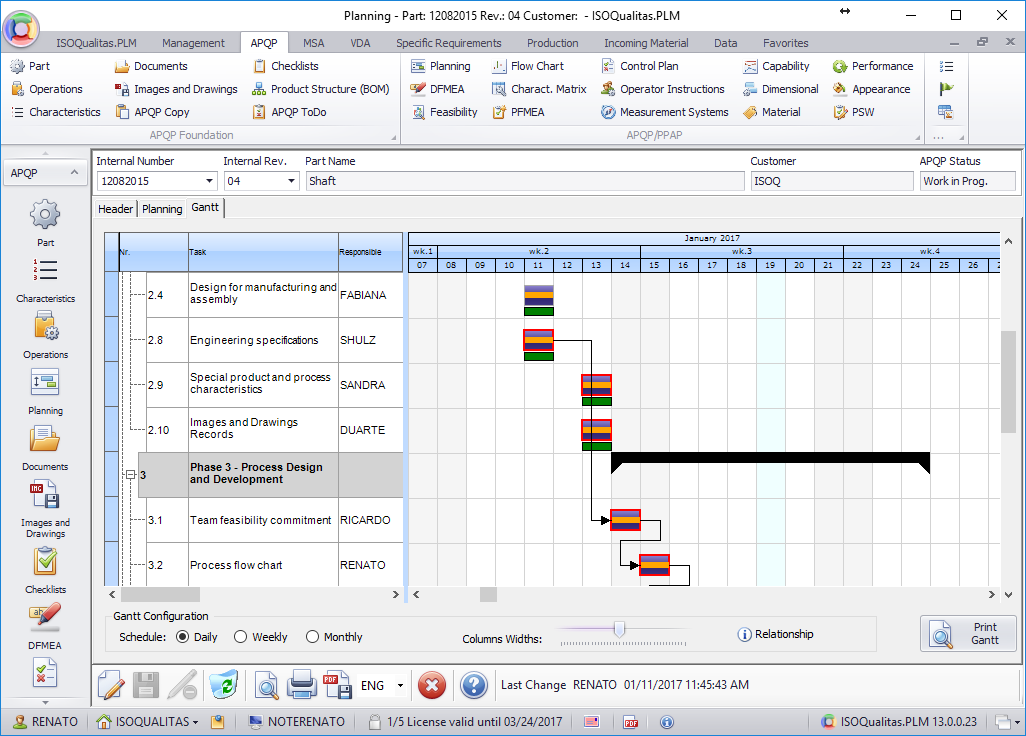

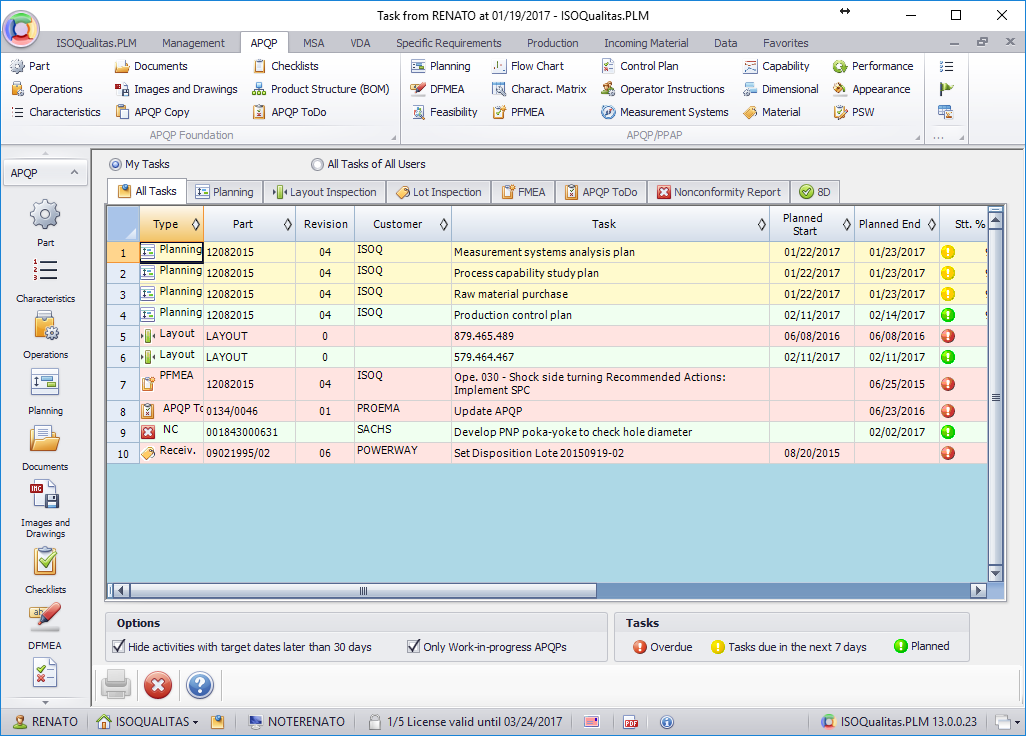

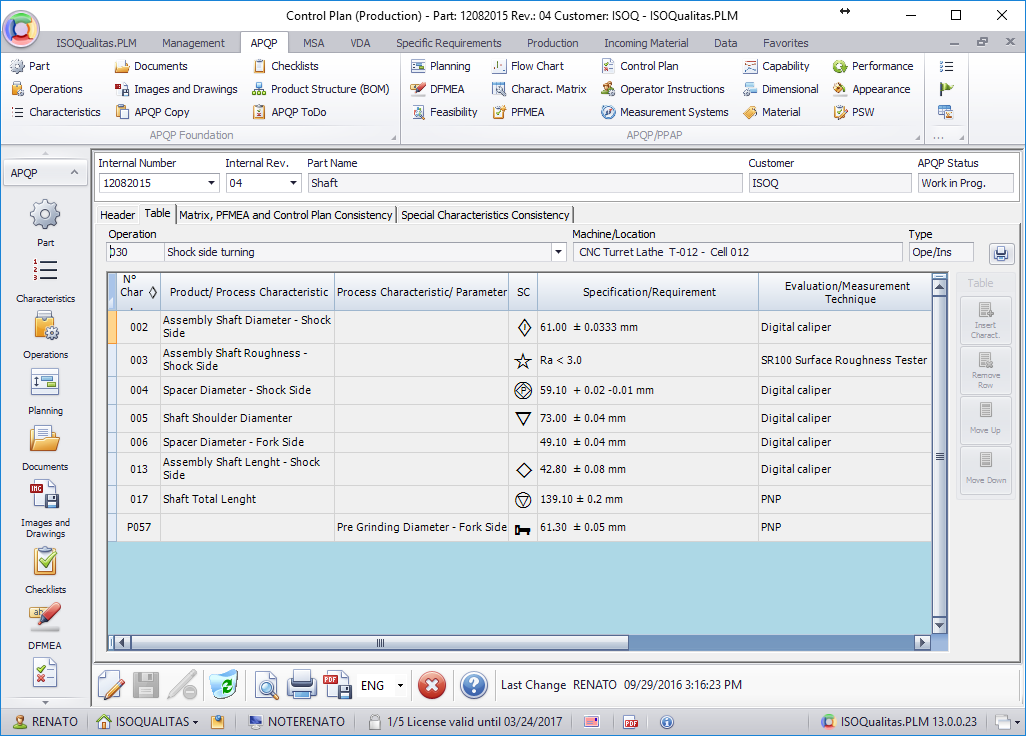

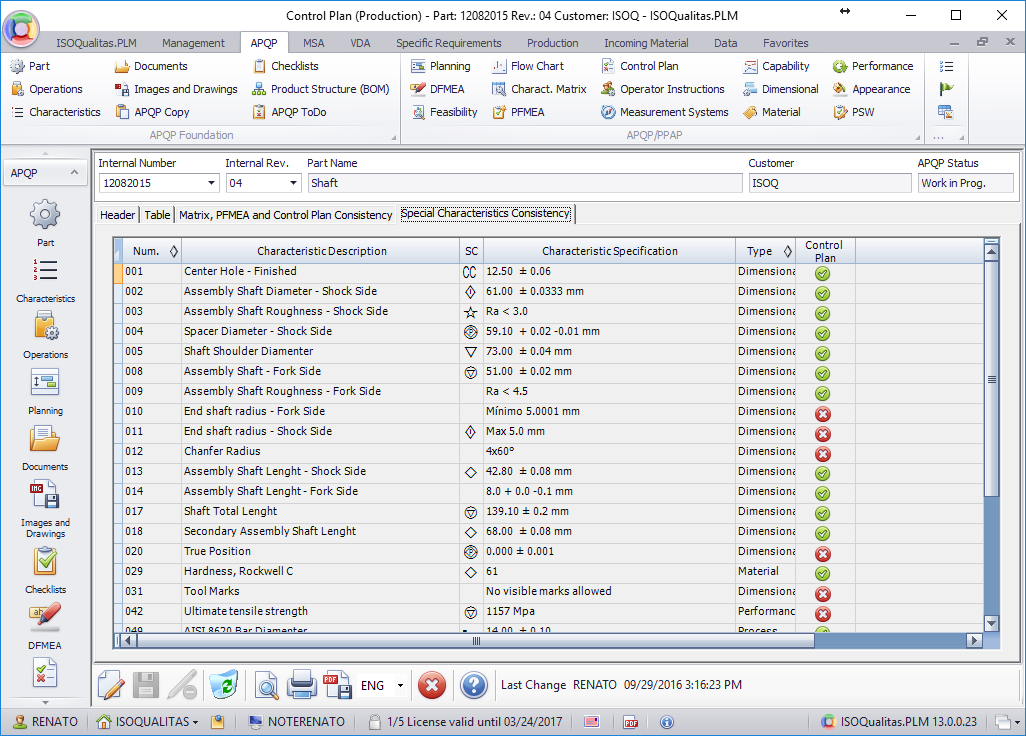

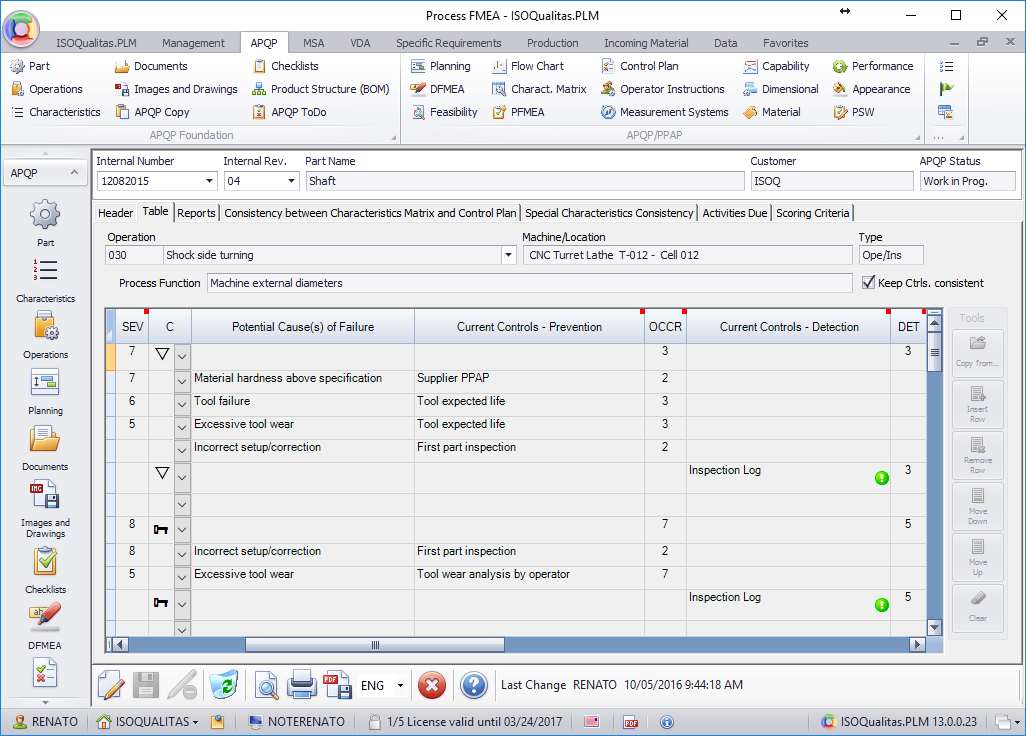

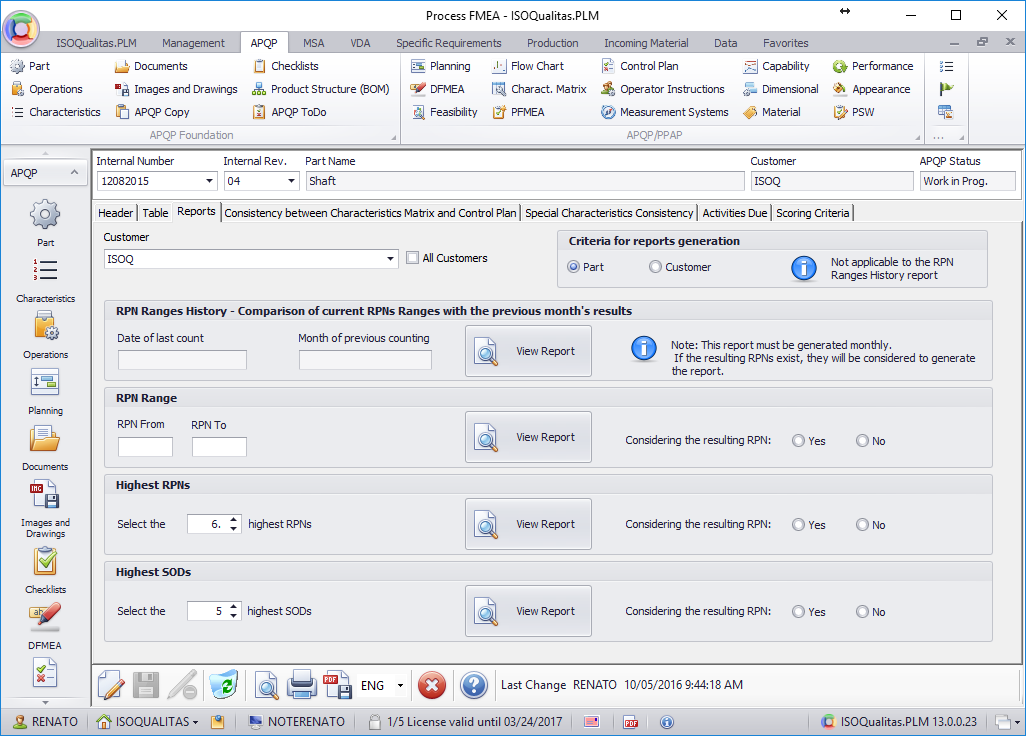

Click the i icon to view a description of the screen. Click the bottom right of the screenshot to view it in full screen. The software interface is available in English, Spanish, and Portuguese; reports can be printed in English, Spanish, German, French, Italian, and Portuguese.

|

CLICK HERE: Download our Brochure

The 5 core process areas of ISOQualitas.PLM: Product Development, Manufacturing Process, Process Validation & Approval, Production, and Product Performance & Feedback.

Join our Consulting Partner Program We are actively looking for Quality Management consultants who work with auto parts manufacturers to partner with us. ISOQualitas provides an opportunity for our consulting partners to:

Flevy manages the Consulting Partner Program for ISOQualitas. If you are a consulting firm interested in participating in our program, please contact us at isoqualitas@flevy.com. If you are an auto parts manufacturer interested in either seeing a demo of ISOQualitas.PLM or speaking with a consulting partner, please contact us here. |

TO BE ADDED.

|

ISOQUALITAS ARTICLES & NEWS

|

|

Download our FREE Strategy & Transformation Framework Templates

Download our free compilation of 50+ Strategy & Transformation slides and templates. Frameworks include McKinsey 7-S Strategy Model, Balanced Scorecard, Disruptive Innovation, BCG Experience Curve, and many more. |