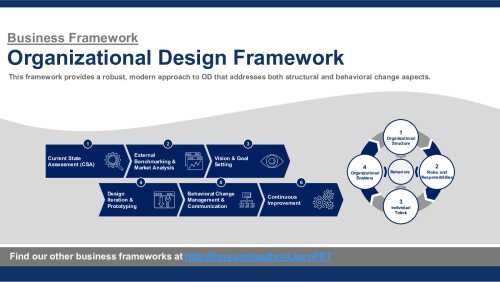

Editor's Note: Take a look at our featured best practice, Organization Design Toolkit (103-slide PowerPoint presentation). Recent McKinsey research surveyed a large set of global executives and suggests that many companies, these days, are in a nearly permanent state of organizational flux. A rise in efforts in Organizational Design is attributed to the accelerating pace of structural change generated by market [read more]

Just-in-Time vs. Just-in-Case: An Inventory Dilemma

* * * *

Has the time come where Just-in-Time (JIT) inventory levels need to be changed to Just-in-Case levels?

With the present and at least near future volatility of the economy, this may prove to be the case. The answer lies within each company’s own supply chain and decided upon based on each company’s individual requirements.

Inventory is considered one of the seven wastes in a lean manufacturing environment. It is any material over and above what is required for use in the process. The JIT environment basically works much like this: a piece per process > one piece delivered > one piece processed > one piece shipped. Any and all inventory on hand after this process can be viewed as waste.

There is no such thing as the ideal situation and it’s quite impractical. Thus, inventory is carried within the facility. In practice just about every company carries inventory of some magnitude. And thus many issues ensue – excess storage requirements, carrying costs, increased material handling and obsolescence. The real concern should lie within the raw materials inventory levels as finished goods and sub-assemblies are in company’s control – based upon customer service levels and on-time delivery rates.

Over the past several months many small companies have shuttered their businesses. Much of this occurred when a primary supplier shutdown operations and damaged your delivery performance.

Under these circumstances perhaps it is time for the remaining small manufacturers to take a good hard look at their suppliers and ask the following questions:

- How well do you know your first, second and third tier suppliers?

- Are any of them at risk of closing their doors and catching you off guard?

- Have you looked at their financial health?

Maybe the time has come to get to know them better. Harks back to making your suppliers your business partners. The slightest change or disruption upstream can cause a major effect downstream. It might be a good idea to carry a few weeks inventory to protect the company until the risk potential with this supplier can be evaluated. Perhaps a visit to this third tier supplier would be in order to avoid higher future costs.

Start this process by reviewing some of the more vulnerable suppliers. For example: if you are in the automobile industry start by checking the health and stability of suppliers you share with the North American automakers.

In any industry, in order to implement JIC, and to determine how much and type of inventory need to carry these questions require honest answers:

- How difficult will it be to source replacement parts?

- How long does it take to get customer approval to move the tooling?

- How much testing is required if a new supplier is needed in an emergency?

- How long can you delay in shipping to your customers before it affects relations?

- How much space will be required to carry enough stock in case of emergency?

The answers to these questions will point the way to determining the on-hand inventory levels. In addition, with good strategy and procedures it should also help to determine which components are at the greatest risk.

Please keep in mind that JIC could be a temporary solution to a temporary problem. It is extremely expensive to carry JIC inventory for every part, so the decision needs to be made as to which parts are the most critical. Be aware, the carrying cost may increase exponentially, at least in the short run. Consider JIC an insurance policy but when the crisis is over re-think the policy and return to JIT and LEAN.

Do You Want to Implement Business Best Practices?

You can download in-depth presentations on 100s of management topics from the FlevyPro Library. FlevyPro is trusted and utilized by 1000s of management consultants and corporate executives.

For even more best practices available on Flevy, have a look at our top 100 lists:

- Top 100 in Strategy & Transformation

- Top 100 in Digital Transformation

- Top 100 in Operational Excellence

- Top 100 in Organization & Change

- Top 100 Management Consulting Frameworks

These best practices are of the same as those leveraged by top-tier management consulting firms, like McKinsey, BCG, Bain, and Accenture. Improve the growth and efficiency of your organization by utilizing these best practice frameworks, templates, and tools. Most were developed by seasoned executives and consultants with over 20+ years of experience.

Readers of This Article Are Interested in These Resources

|

|

145-slide PowerPoint presentation

|

|

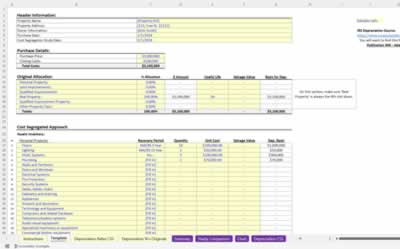

Excel workbook

| |||

About Stuart Rosenberg

Stuart Rosenberg has a regional reputation as a subject matter expert and published author in Supply Chain Management and Lean Six Sigma disciplines. He has outstanding knowledge of all inventory control functions in both manufacturing and distribution environments, and grasp of all data involved with all inventory systems, cost analysis and product evaluations. Stuart has initiated, managed and oversaw all inventory control environments and situations, with direct supervision of various warehouse locations, to certify continuous accuracy, reliability and integrity of companies inventory operational and financial data. He has influenced, counseled, and directed major revisions to enhance companies operational efficiencies. You can read more about Stuart on his blog and find him on Linkedin here. Stuart also has several thought leadership papers available on Flevy (srosenbe7).

Top 10 Recommended Documents